The title of this work was perhaps the hardest part to translate. Dragotsennost’ is typically used to mean “gemstone”, but clearly here, the context includes the gold, silver, embroidery, stones, and all other components of ecclesiastical embroidery. I was greatly tempted to translate it as “Bling”, but this word is a bit mundane, given the elevated subject matter. As such, I have translated it as Opulence (the Russian word literally means “high cost”). The article ends with an interesting comparison between liturgical embroidery of the middle ages vs. recent times after the fall of the Soviet Union, both times of rapid expansion of the church in Russia.

Opulence in Ecclesiastical Embroidery

A translation of Хребина, Т.В. “Dragotsennost’ v tserkovnom shit’e.” Isvestija Rossijskogo gosudarstvennogo pedagogicheskogo universiteta im. A.I. Gertsena. Volume 18, Issue 44. 2007, pp. 289-293.

[Translation by John Beebe, known in the Society for Creative Anachronism as Master Ivan Matfeevich Rezansky, OL.]

[Translator’s notes: I’ve done my best to convey both the meaning and style from the original. Comments in square brackets and footnotes labeled “jeb” are my own. This document may contain specialized vocabulary related to embroidery, archeology, Eastern Orthodoxy, or Russian history; see this vocabulary list for assistance with some of these terms. This translation was done for my own personal education, and is provided here as a free resource for members of the Society for Creative Anachronism who may be interested in this topic but are unable to read Russian. I receive no compensation or income for this work. If you like this translation, please take a look at other translations I have made available on my blog.]

The article in the original Russian can be found here:

https://cyberleninka.ru/article/v/dragotsennost-v-tserkovnom-shitie

This work is presented by the Department of Russian Art of the I.M. Repin Institute. The supervisor is Candidate of Theology, Candidate of Architecture, Professor Father Superior Aleksandr (Feodorov).

Research works devoted to medieval Russian ecclesiastical embroidery have primarily focused on the study of historical and artistic questions. Questions of material science have received little attention. The necessity to fill this gap arose in connection with today’s revival of the traditions of church embroidery.

The decoration of fabric with embroidery was well known in the lands of Rus’ since the most ancient of times. The entire Russian way of life was caught up by fabrics, richly decorated with patterns, which accompanied the life of every individual from birth to death. They were indicators of wealth, and a characteristic of the moral quality of any family, regardless of their social status. Every home had a solarium [svetlitsa], the brightest and neatest rooms, or just a corner near a window. Here, they would engage in preparing fabrics that were needed for the household. There were no artificial sources of light; firelight was rarely used for this purpose. In Rus’, winter was typically long, and this meant an extended period of darkened daytimes. It would not be possible for ordinary peasant women to engage in ecclesiastical embroidery at this time as it would have been in spring, summer or fall — the brightest times of the year, suitable for such serious obedience — which were filled with agricultural work. Therefore, from the very beginning, embroidery for the church must have been carried out by professional artisans. Only the solaria of the households of the Great Princes, royals and some boyars would have created items of ecclesiastical embroidery.

The great demand for the manufacture of ecclesiastical artwork arose in Rus’ soon after the conversion to Christianity, just as churches were being built in every city and princely court. The first Greek priests, regents, architects, and iconographers from Byzantium brought with them shrines, icons, liturgical vessels, and ecclesiastical textiles. Likewise, they brought with them the traditions and techniques of church embroidery over a long period of time, importing materials right up until the fall of the empire.

The character of preparing items of church textiles suggests a high degree of division of labor. The creation of a single item may have included the efforts of icon painters (specialists in drawing the cartoon, or depicting nature, or writing inscriptions), dyers, jewelers, embroiderers, sewers, and other artisans. In addition, artisans would specialize in facial [lichnyj] [1]”Facial” [lichnoe] – the face and other parts of the body which are not covered by clothing., body [dolichnyj] [2]”Body” [dolichnoe] – the parts of the composition, including the landscape, buildings, clothing, etc. — everything except the face and uncovered parts of the body., or ornamental embroidery. This work was highly paid. Only very wealthy families could maintain such an atelier.

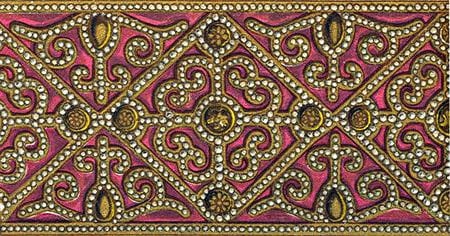

Considering the materials used in ecclesiastical embroidery, it’s clear that they were all imported, with the exception of linen fabric: silk fabric and thread, gold, silver and gilt threads, jeweled details from precious metals, gems, pearls and beads. Foreign merchants obtained these items from distant lands: Byzantium, Persia, India, China. The distance and the dangers of these trade routes, wars, uprisings, looting and pillage, steep taxes, and in Byzantium and China, the prohibition against the export of certain goods — these all played a direct role in the steep cost of materials.

Gold and silver have enjoyed popularity in Russia since ancient times, as attested by archeological finds. Foreigners were amazed by their abundant use in the decoration of churches and temples, but also in festive national outfits and in everyday life. For a very long time, Rus’ had no precious metals of its own; great quantities of them were purchased from Western Europe. The first examples from home-grown sources were created during the reign of Peter the Great.

The manufacture of goldwork materials — metallic threads[3]Metallic threads – very thin wires [voloki] made by repeatedly pulling (or “drawing”) a cylindrical rod through a row of holes in an iron plate, and then through precious stones of great hardness (ruby, diamond). Classified by: chemical S, color, form of cross-section, and by configuration and texture. and their derivatives, spun thread[4]Spun threads [prjadenye niti] – metallic threads of various types, twisted onto a silk, linen or cotton core. and gimp[5]Gimp [kanitel’] – spirals of thin wire, wound around thin mandrels of various sizes. — for embroidery and weaving was established only in the early 19th century. Most often, they used gimp of various sorts, plate[6]Plate [bit’] – flattened narrow metallic threads, less than 1mm wide. , and spangles.

Threads from pure gold were used in Rus’ until the 14th century. Later they began to use gilt threads — thin silver or bronze wires covered in a thin layer of gold or silver.

Gold-fabrics were imported primarily from Byzantium, and beginning in the mid-14th century, from Persia. Later, fabric from Italy and France was in great demand. It was only at the end of the 16th century, during the reign of Tsar Fedor Ioannovich, that the first manufactory was opened in Russia, establishing the production of brocade[7]Brocade [parcha] – general term in Russia for any fabric with metallic threads.. The business of gold-fabric in Russia took hold in the second half of the 17th century. Several factories were built, but business grew slowly. The assortment and quality of the fabric produced here could not compete with imports. But, production constantly improved, and by the late 19th century, the quality and assortment of brocades reached the highest degree[8]At the beginning of the 20th century, there were 20 factories operating. The largest firm, supplier to the Court of His Imperial Majesty, was the Commercial-Industrial Partnership of P.I. Olovjanischnikov and Sons.” The factories of the Alekseevs, Vyshnjakovs, and Shamshins were also well known..

Right up until the beginning of the 20th century, silk fabric and thread was imported. These materials came at first from Byzantium and China, but later also from Persia, Turkey and Italy. A multitude of fabric items is mentioned in countless historical sources: various monastic records, manuscripts, and economic treaties. They received various names based on their place of manufacture and their ornamentation:

- damask[9]Damask [kamka] – a thin, dual-sided, monochromatic fabric, having a matte design on a shiny background on one side, and a shiny design on a matte background on the other. — “burskaja” [“from Buer”], “misjurskaja” [“from Egypt” — jeb: cf. Arabic مِصر, “Egypt”], “adamashka” [“from Damascus”], “kufter’” [jeb: cf. Persian کبوتر, “dove”], “cheshujchataja” [“scaly”], “strujchataja” [“banded”]

- taffeta[10]Taffeta [tafta] – a smooth or patterned fabric of plain weave, with small transverse ribs created by various thicknesses of warp and weft threads. — “dvoelichnaja” [“double-sided”], “shamarkhanskaja” [“from Samarkand”(?)], “angulinnaja” [“from Angoulême”]

- satin[11]Satin [atlas] – a silk fabric with a shiny surface, achieved through a special weaving method. — “gladkij” [“smooth”], “uzornyj” [“patterned”], “nemetskij” [“German”], “kizilbashskij” [“from the Qizilbash”(?)], “turskij” [“from Tours”], “kitajskij” [“Chinese”]

- velvet[12]Velvet [barkhat] – fabric with a thick, close-cropped nap on the front side, held at the base by a plain or twill weave. — “rymyj” [“excavated”], “kosmatyj” [“shaggy”], “dvoemorkhij” [“double frosted”], “petlevatij” [“looped”], “florenskij” [“Florentine”], “veneditskij” [“from Venice”], “turskij” [“from Tours”], “burskij” [“from Buer”], “kizilbashskij” [“from the Qizilbash”(?)], “kitajskij” [“Chinese”]

- et.al.

During the reigns of tsars Mikhail Feodorovich and Aleksei Mikhailovich, attempts were undertaken to establish the production of silk. In the regions near Astrakhan and Moscow, the first mulberry trees were planted. By order of Peter the Great early in the 18th century, state lands were allocated in the Caucasus for sericulture. By 1762, the number of silk manufacturers had reached 44. It was only by the end of the 19th century, however, that the production of silk fabric developed from the creation of raw materials[13]In 1913, 80% of all raw silk was imported from abroad., because the climate was inhospitable for raising silkworms.

Textiles were typically dyed or painted to the desired shade with the aid of natural dyes. Purple[14]Until the 14th century, these were obtained from Mediterranean mollusks. (red) and indigo[15]Well known since the first millenium BC. It was extracted from “true indigo” (Indigofera tinctoria). For a long time, this was one of the most expensive, and yet also one of the most popular dyes, as it had good color saturation, did not fade from washing, didn’t fade, and gave fabrics durability. (dark blue) were most sought after, and very expensive.

Gems began to appear in Russian embroidery in the 16th century. They could be diaphanous or opaque, sparkling or matte, polished or unprocessed. Precious and semi-precious stones were sourced from many locations in Russia – the Urals, Altai, the Eastern Sayan mountains, Central Asia, and the Caucasus. At the same time, stones were also purchased in great quantities from foreign merchants. The most commonly used stones , according to historical sources, were:

- Yellow: topaz, yellow sapphires

- Red: so called “red sapphires” (rubies), “laly” and “chervtsy” [“worms”] (low-quality rubies), garnets (almandines, pyropes)

- Blue: blue sapphires, “bausy” [kyanite or tourmaline]

- Green: emeralds, beryl

Pearls for ecclesiastical embroidery were obtained “overseas,” meaning they were of the highest quality[16]Pearls found in northern rivers of Rus’, used only for the decoration of fabric..

Even beads were purchased up until the late 19th century in enormous quantities. The brilliant Russian scholar M.V. Lomonosov unsuccessfully called for and attempted to establish their mass manufacture in Russia in the late 18th century. He created the first and, it would turn out, the only batch of metal and glass beads. Only in the late 19th century was the production of material finally established.

Based on the facts presented above, it is possible to draw the following conclusion about the characteristic quality of medieval Russian church embroidery: the labor and materials were extravagantly expensive. This artwork was therefore rare and unique.

Even modern church embroidery is a little studied form of ecclesiastical artwork. It is an integral part of worship and of the church interior, and must always meet certain requirements prevailing in the Russian Orthodox Church. These provisions primarily relate to ideological content, compliance with dogmatic iconographic canon, and masterful incarnation of the material. Embroidery displayed in the church, on par with works of other ecclesiastical artwork, “serves,” affects a setting, and overall creates an atmosphere in each particular parish that is unique, and yet at the same time united in spirit with all other churches during the Divine Service.

Certain circumstances in our history have given rise to the necessity to quickly find all the prerequisite items necessary for regular services. Ruined churches rise without their interior decorations. Such a situation requires great one-time material costs. No church is able to quickly resolve this problem. Impatience appears on the part of the priesthood and the congregation. Church embroidery is therefore carried out hastily. This situation naturally affects its ideological, symbolic, artistic and technical quality. Such extravagance in modern church embroidery is an almost unattainable quality. Until the need to restore this quality is understood, it is impossible to speak about the normal development of church embroidery.

At this moment, there are two explicit tendencies directly concerning the problem of luxuriance arising from the desire to embroider “both a lot and quickly”: the simplification of works, and the use of poorer materials. Both negatively affect the quality of ecclesiastical embroidery.

The value of works of modern-day ecclesiastical embroidery has plainly not yet been defined by the clergy, nor by the donors, nor by the embroiderers themselves. Practically every artisan is constantly struck by the fact that by the time they complete an order, its cost has increased many fold. Such is the fate of ecclesiastical embroidery. On the one hand, the work itself is so delicate and meticulous that a few hours of sewing covers only a few square centimeters of fabric. On the other hand, there’s a great deal of unpredictability in the final result. It is impossible to foresee every nuance in the execution of this artform. Every work is an experiment, with negative results being corrected, sometimes repeatedly. The unfinished work increases, and accordingly the item becomes more and more expensive.

The manual, painstaking work in modern ecclesiastical embroidery is recognized to be very slow and expensive. There is a widespread introduction of machine and computerized embroidery in church textiles. Today some artisans, seeking to survive economically, acquire embroidery machines. This is a natural process, and has nothing in common with authentic art, as it engages in imitation where to do so is forbidden. All too often, these artisans will, without thinking, brush aside one of the most important principles of the embroidery of faces – instead of using 2 tones of the same color, they may use as many as 20. They are employed pictorially via the art of “artistic smoothness.” This in turn distorts the traditions of liturgical art.

Modern synthetic materials undoubtedly worsen the appearance of the work, even if the embroidery is meticulous. This change in the properties of artistic materials can cause unpredictable results. Therefore, it is necessary before their selection to take into account their raw materials, as well as their physical and chemical compatibility. The use of unequal, expensive and cheap materials in a single item can result in the high-end elements beginning to appear cheap. Glass, cheap beads, plastic, and gaud do not add nobility. Even the most exquisite technique of use can save such a performance.

Awareness of luxuriance as a particular characteristic of ecclesiastical embroidery can be seen in its further development. It is necessary to inform members of the priesthood and potential benefactors of these specific features. An accurate assessment of the money spent on raw materials for the manufacture of a specific embroidered ecclesiastical item can drastically affect not only its artistic, but also its liturgical quality.

Footnotes

| ↟1 | ”Facial” [lichnoe] – the face and other parts of the body which are not covered by clothing. |

|---|---|

| ↟2 | ”Body” [dolichnoe] – the parts of the composition, including the landscape, buildings, clothing, etc. — everything except the face and uncovered parts of the body. |

| ↟3 | Metallic threads – very thin wires [voloki] made by repeatedly pulling (or “drawing”) a cylindrical rod through a row of holes in an iron plate, and then through precious stones of great hardness (ruby, diamond). Classified by: chemical S, color, form of cross-section, and by configuration and texture. |

| ↟4 | Spun threads [prjadenye niti] – metallic threads of various types, twisted onto a silk, linen or cotton core. |

| ↟5 | Gimp [kanitel’] – spirals of thin wire, wound around thin mandrels of various sizes. |

| ↟6 | Plate [bit’] – flattened narrow metallic threads, less than 1mm wide. |

| ↟7 | Brocade [parcha] – general term in Russia for any fabric with metallic threads. |

| ↟8 | At the beginning of the 20th century, there were 20 factories operating. The largest firm, supplier to the Court of His Imperial Majesty, was the Commercial-Industrial Partnership of P.I. Olovjanischnikov and Sons.” The factories of the Alekseevs, Vyshnjakovs, and Shamshins were also well known. |

| ↟9 | Damask [kamka] – a thin, dual-sided, monochromatic fabric, having a matte design on a shiny background on one side, and a shiny design on a matte background on the other. |

| ↟10 | Taffeta [tafta] – a smooth or patterned fabric of plain weave, with small transverse ribs created by various thicknesses of warp and weft threads. |

| ↟11 | Satin [atlas] – a silk fabric with a shiny surface, achieved through a special weaving method. |

| ↟12 | Velvet [barkhat] – fabric with a thick, close-cropped nap on the front side, held at the base by a plain or twill weave. |

| ↟13 | In 1913, 80% of all raw silk was imported from abroad. |

| ↟14 | Until the 14th century, these were obtained from Mediterranean mollusks. |

| ↟15 | Well known since the first millenium BC. It was extracted from “true indigo” (Indigofera tinctoria). For a long time, this was one of the most expensive, and yet also one of the most popular dyes, as it had good color saturation, did not fade from washing, didn’t fade, and gave fabrics durability. |

| ↟16 | Pearls found in northern rivers of Rus’, used only for the decoration of fabric. |