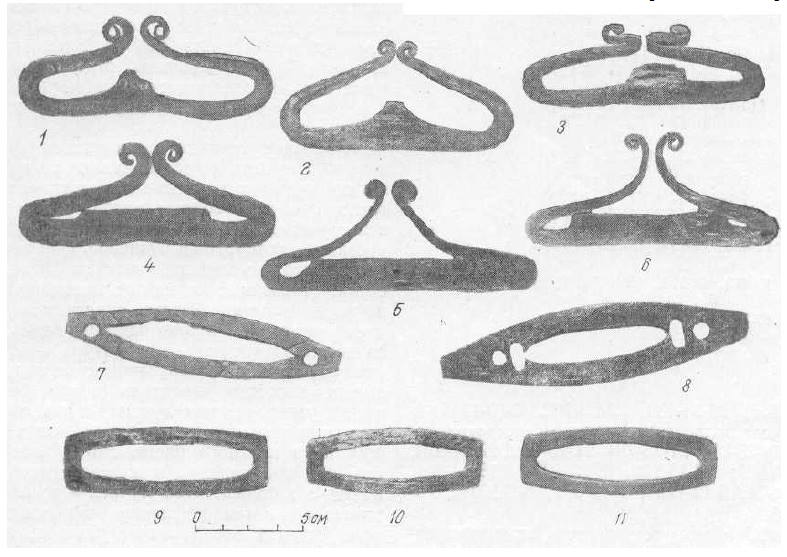

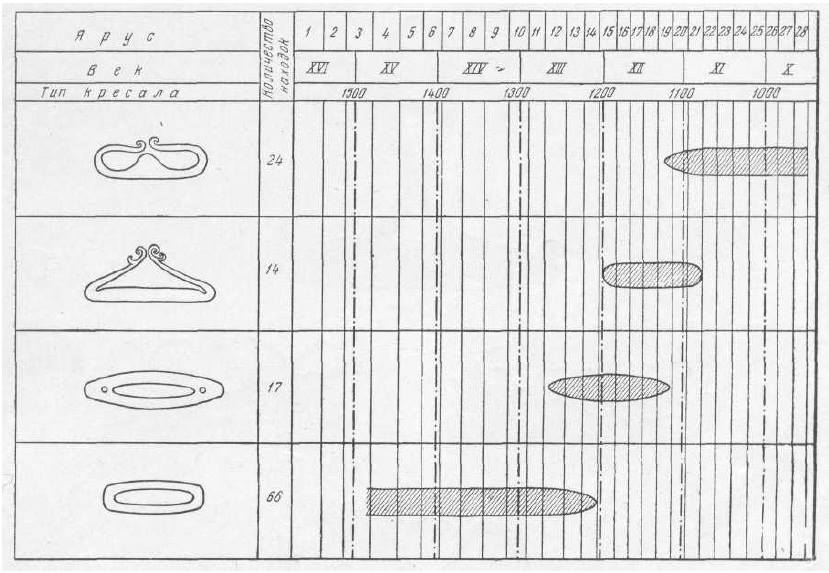

The archeological excavation of the Nerevsky End neighborhood in Novgorod in the 1950s revealed a massive amount of material about everyday life in medieval Novgorod in one of its busiest neighborhoods. The current post is a translation of an article about one major aspect of that life – its blacksmithing community, through evidence of smithies, iron production sites, and a multitude of iron and steel items that were discovered during the dig. The author covers these areas in great detail, giving some historical context on manufacture in the 10th-16th centuries, before delving into descriptions of each type of item found, and where possible, how those items evolved over time, mainly as the result of the move from production on spec to mass production as Novgorod reached its height in the 14th century, followed by its slow decline after it was subjugated to Moscow by Ivan III. Along the way, we get a great view of the tools and everyday items used by Novgorod’s inhabitants. In particular, the author goes into great depth describing the evolution of knives, axes, and fire strikers, which underwent a number of changes over the course of time.

Note that this article contains a number of “passport” or provenance identification numbers for items that were excavated in Novgorod, in the form of three numbers in A-B-C format. Information on how to decipher these IDs is available in my blog post https://rezansky.com/decoding-references-to-items-from-novgorod-archeological-digs/

The Blacksmithing Arts of Novgorod the Great

A translation of Колчин, В.А. «Железообрабатывающее ремесло Новгорода великого. (Продукция, технология).» Труды Новгородской археологической экспедиции, Том II. Материалы и Исследования по Археологии СССР [МИА], № 65. 1959 (2). с. 7-120. / Kolchin, V.A. “Zhelezoobrabatyvajuschee remeslo Novgoroda velikogo (Produktsija, tekhnologija).” Trudy Novgorodskoj arkheologicheskoj ekspeditsii, Tom II. Materialy i Issledovanija po Arkheologii SSSR, No. 65. 1959 (2), pp. 7-120.

[Translation by John Beebe, known in the Society for Creative Anachronism as Boyarin Ivan Matfeevich Rezansky, OL.]

[Translator’s notes: I’ve done my best to convey both the meaning and style from the original. Comments in square brackets and footnotes labeled “jeb” are my own. This document may contain specialized vocabulary related to embroidery, archeology, Eastern Orthodoxy, or Russian history; see this vocabulary list for assistance with some of these terms. This translation was done for my own personal education, and is provided here as a free resource for members of the Society for Creative Anachronism who may be interested in this topic but are unable to read Russian. I receive no compensation or income for this work. If you like this translation, please take a look at other translations I have made available on my blog.]

[The article in the original Russian can be found here:

https://www.twirpx.com/file/761637/. ]

Part I – Introduction and Methods of Study

Novgorod the Great, as with many medieval Russian settlements, was a town of artisans. Soviet historical literature, especially that of the post-WWII era, has clearly proven that high level of development of medieval Russian cities and the widespread distribution of their urban craftsmen. Archeological material has served as a primary source allowing us to refute many old speculations of bourgeois and other historiography.

The excavations in Novgorod, and in particular those of the Nerevskij End, have provided an enormous amount of factual material characterizing the high material culture of this medieval city, including its artistic production.

The production workshops uncovered by these digs and especially the large quantity of artistic tools made of iron, steel, wood, non-ferrous metals, and other materials speak to the manifold artistic activities of medieval Novgorodians. Especially important for the characterization of local Novgorod artistic production are the abundant finds of waste material, semi-fabricated items, manufacturing defects, and finally, source material for this or that production in the form of iron blooms, strips of iron and steel, ingots of non-ferrous metals, blanks made from bone, pieces of amber, glass, and so forth.

These items all allow us to say that there was mass production of craft items, satisfying the needs and demands of the Novgorodians (including blacksmithed items found during the excavations), as well as production by Novgorodian craftsmen intended for the many rural markets of the Novgorod lands, as we shall see below, created using a high level of technical culture in the realm of ironworking. This local production is also shown by the composition of metal in researched items, which we shall discuss further below.

New archeological material serving, as we have seen, as source material for the study of the history of this craft, and the introduction of new physical methods of studying materials allows us to expand the circle of questions of the history of medieval Russian industry and to limit our scientific consideration to that of a single city.

This essay’s tasks included the systematization of an enormous collection of finds: the products of Novgorod’s blacksmithing art, their chronology, and their typology. Aside from this, based on widespread use of physical research (structural and other analyses of examples), we have studied the technique of production for all categories of ferrous metal items found in the Nerevsky End. The second part of our work, which the author is working on now, shall address questions of the economy, social structure, and other phenomena related to the blacksmithing arts.

Over 5 years of archeological study (1951-1955) in the Nerevsky excavation, amongst a huge number of items made of wood, bone, leather, clay, glass, stone, non-ferrous metal, fabric, and other materials, more than 10,000 items of ferrous metal were discovered. These included nearly every category of items made of iron or steel which existed in medieval Rus’. It is worth noting the specification of Novgorod’s cultural layer – its high humidity, which preserved birchbark letters, wood and in general all organic items for science – contributed equally to the preservation of blacksmithed items.

The process by which items of ferrous metals rust in the cultural layer for most archeological monuments significantly damages or frequently completely destroys iron items. The high level of humidity in Novgorod’s soil created such conditions where iron which became buried was covered only in a thin layer of rust, and further oxidation of the metal ceased or was significantly slowed. As a result, items of iron and steel which were found in the Nerevsky dig appeared before the archeologists in almost exactly the same condition as they were when they first were interred (whole or destroyed). Following an insignificant amount of cleaning and sanding of the surface, these metallic items were returned to their natural working state. Honed knives from the 10th-11th centuries became sharp and completely able to whittle wood, axes became able to hew, drills were able to create holes, and scissors were able to cut.

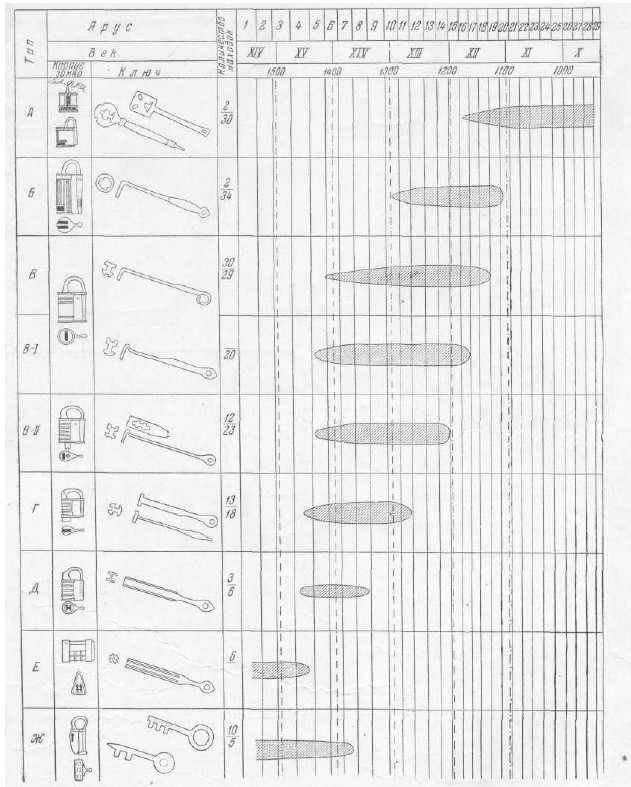

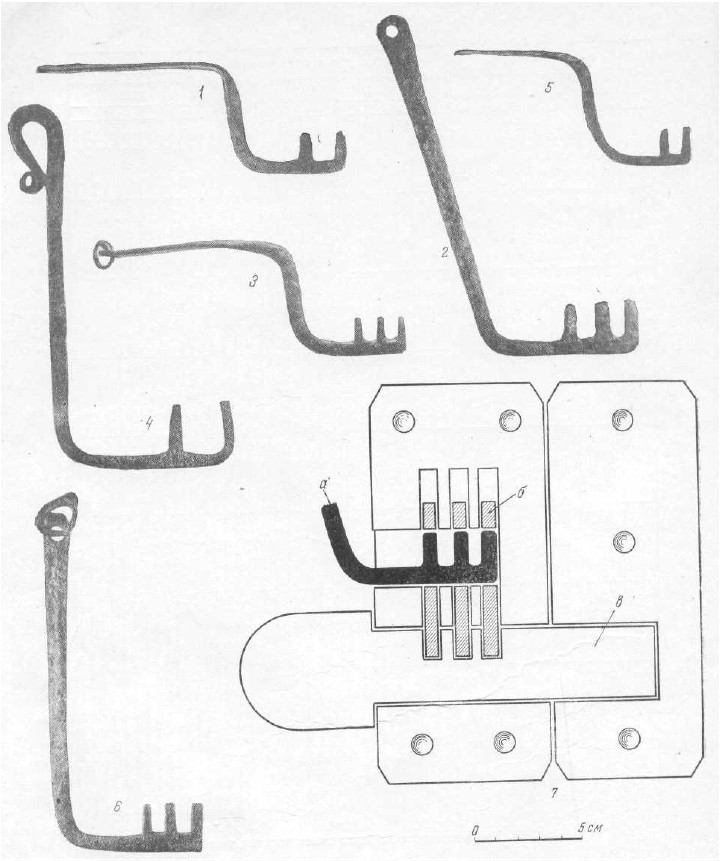

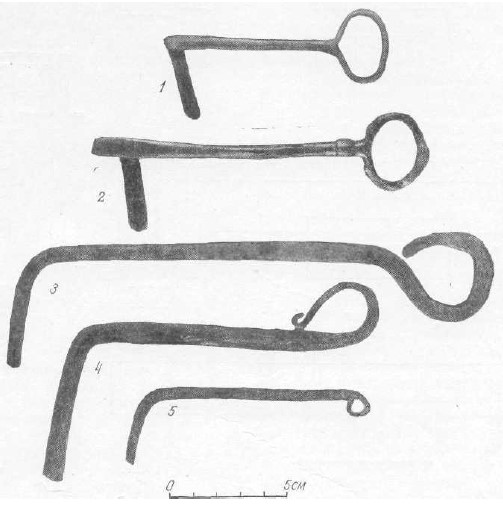

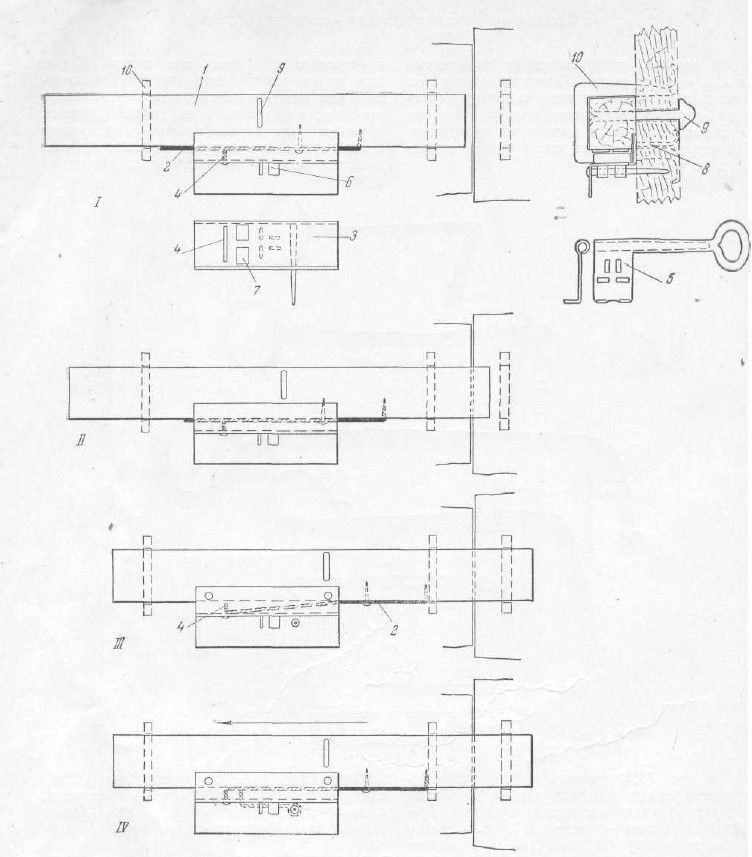

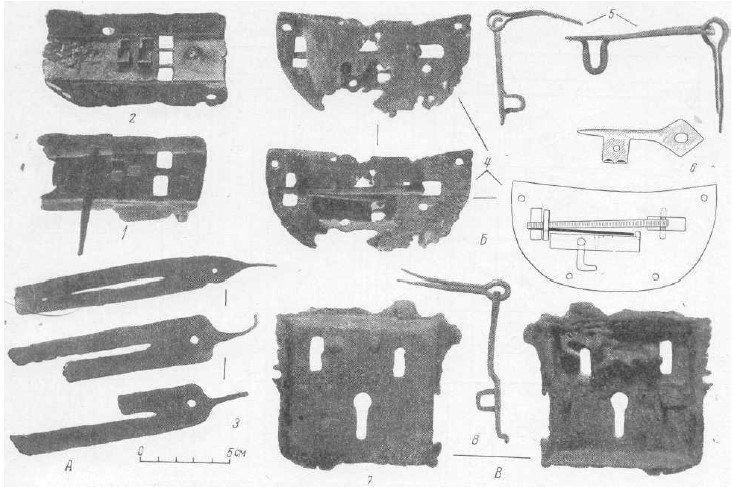

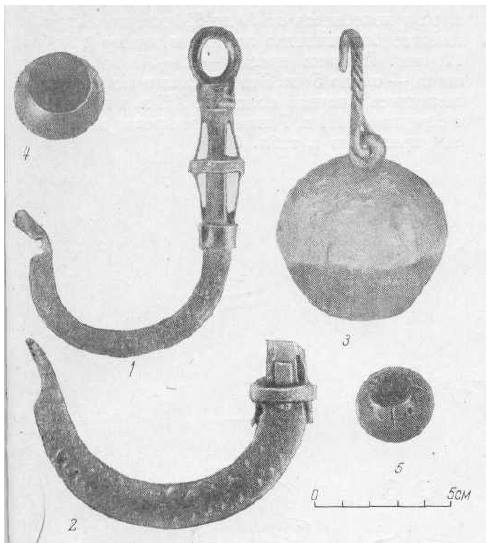

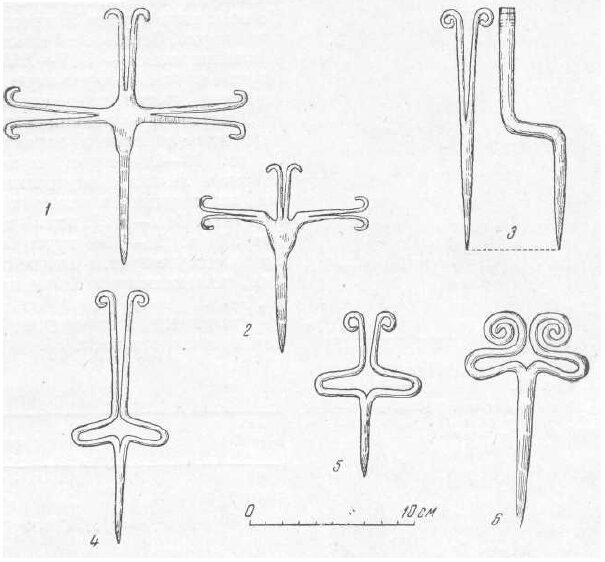

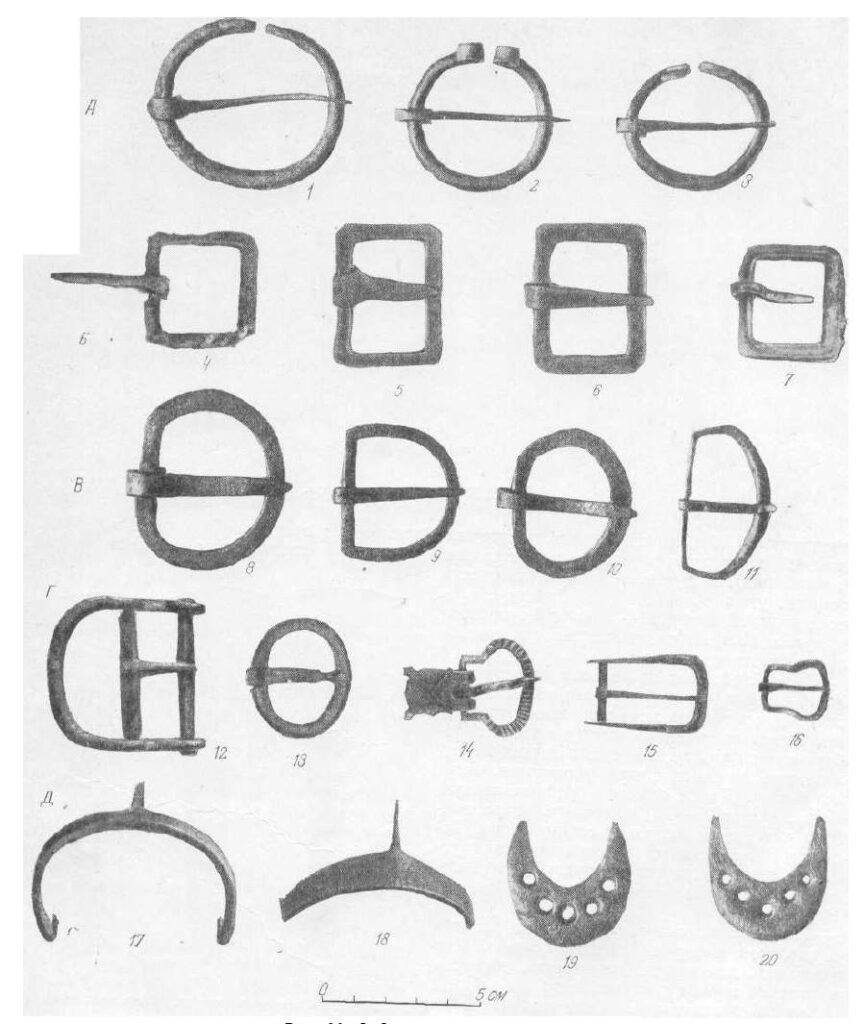

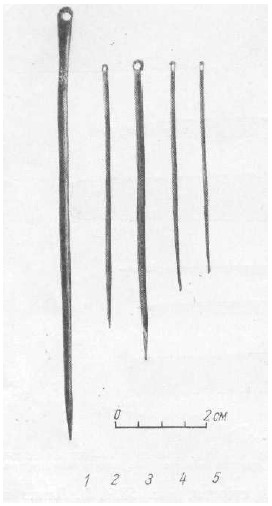

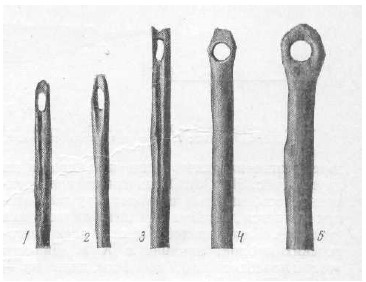

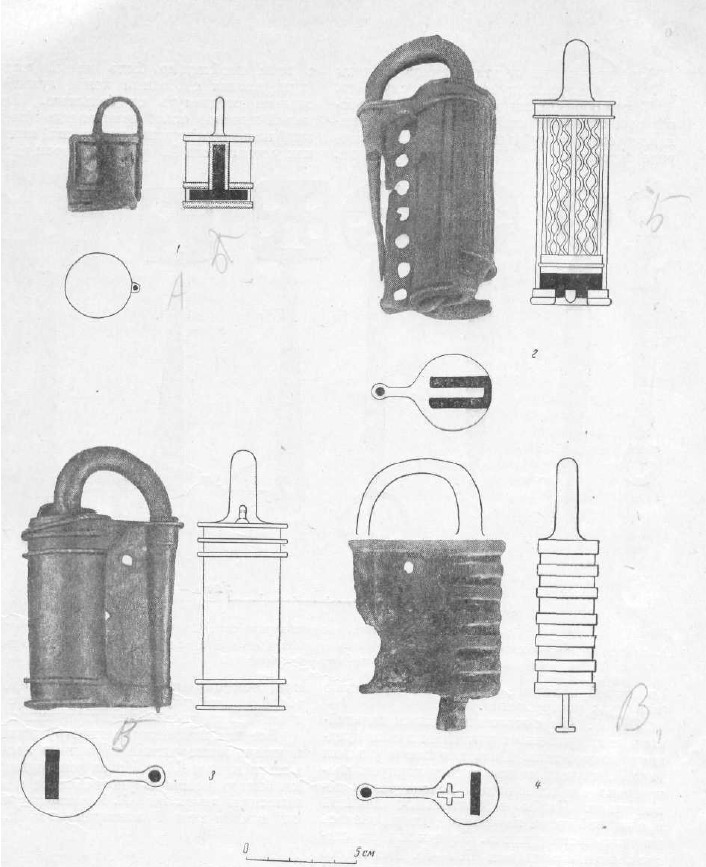

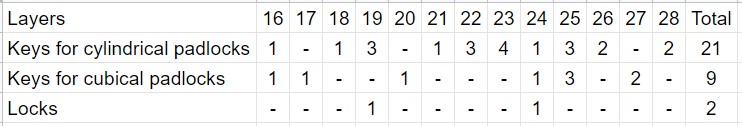

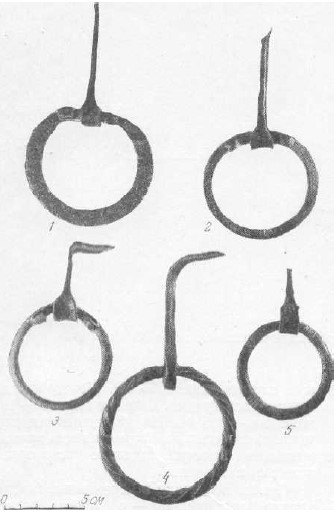

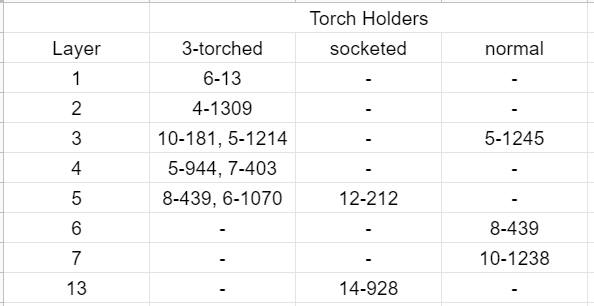

During the Nerevsky dig in layers from the 10th-15th centuries, among ruined dwellings, in outbuildings and other constructions, in workshops, estate courtyards, and along the pavements of the Velikaya, Kholop’ya and Kuz’modem’yanskaya streets, finds have included the following items: anvils, hammers, tongs, files, bits, nail headers, tweezers, chisels, crucible tongs, jeweler’s tweezers. Among woodworking utensils, they have found: axes, drills, bits, saws, adzes, scrapers, drawknives, various cutting tools, chisels, cold files, and nail pullers. Other types of tools have included knives, scissors, awls, needles, razors, bone cutters, bast awls,[1]jeb: Rus. кочедык, kochedyki, a curved awl, used for weaving items from bast. and strainers [?? – Rus. дрышлаг, dryshlag]. Agricultural tools included coulters, sickles, scythes, shovel blades, hoes, beeswax cutters, cowbells, fetters, fishhooks, traps (?? – Rus. остроги, ostrogi, “prisons”), harpoons, lures, and boathooks. Weapons have included arrows, spears, chainmail, armor, maces, battle axes, shield bosses, and parts of swords and sabers. From horse tackle, they have found stirrups, bits, cheekpieces, spurs, scrapers, and horseshoes. A large quantity was made up of household items and utensils: padlocks, interior locks, keys, springs, overlays, covers, probes, door hooks, doorknobs, hinges, handles, hoops and lugs from wooden buckets, nails, rivets, collars, mounting brackets, scales, weights, torch sconces, flint strikers, candlesticks, iron bearings, frying pans, pan handles, various chains, and collars. Costume items have included pins, fibulae, buckles, clips, rings, and boot heel plates. A musical instrument, a mouth harp, was also found. Finally, prison shackles were discovered, a first in Russian archeology.

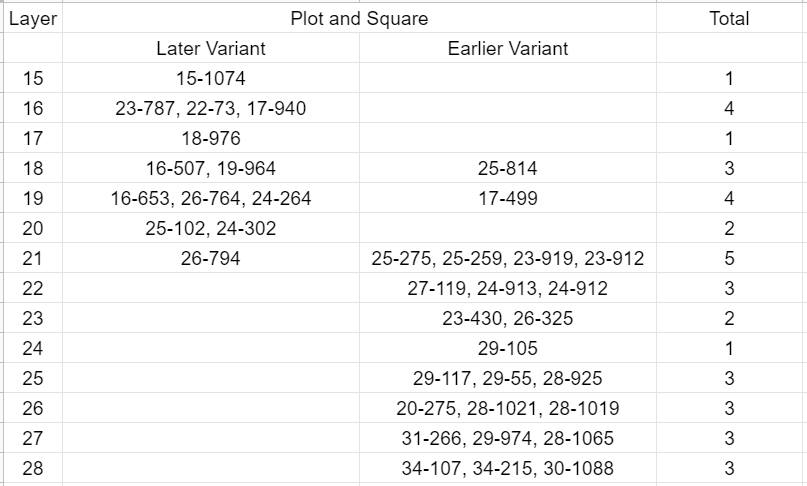

While studying the typology and chronology of these blacksmithed items, we always firmly date all items found in the dig based on the location of their discovery (plot and layer). As such, naturally, preservation of the cultural layer at the location of each find is taken into account. The justification for this chronology was presented by us in “The Topography, Stratigraphy and Chronology of the Nerevsky Excavation,” published by us in the first volume of the Works of the Novgorod Archeological Expedition.[2]Kolchin, B.A. “Topografija, stratigrafija, i khronologija Nerevskogo raskopa.” Trudy Novgorodskoj arkheologicheskoj ekzpeditsii. Tom I. MIA. Iss. 55 (1956), pp. 44-137. We would direct all who wish to further acquaint themselves with the chronology of the Nerevsky dig to that work. The wider typological dating of objects in the archeological record has always agreed with our stratigraphy.

For the study of the technological methods used to create the blacksmithed items under our review, we have widely used metallographic analysis, as well as spectroscopic analysis and measurements of the hardness of the metal in these items. The author performed the metallographic analyses himself in the Laboratory for Structural and Spectral Analysis of the Chair of Archeology in the History Department of Moscow State University.

In our work “Ferrous Metallurgy and Metalworking in Medieval Rus’,”[3]Kolchin, B.A. “Chernaya metallurgija i metalloobrabotka v drevnej Rusi.” MIA. Iss. 32 (1953). as a result of mass microstructural analysis, I was able to track the basic technological methods used in blacksmithing in medieval Rus’ in the 10th-12th centuries. At the root of this technology lay the principle of versatile combination of iron and steel in the construction of items.

For our current work, the primary method of research was microstructural analysis, which we used on 276 items of ferrous metal. For this analysis, a sample was cut from each of the items under study. In each case, the samples were cut from the working area of each item (most commonly, these were blades used for cutting, stabbing or chopping) in cross-section. A thin, cross-section cut was made on each sample, more fully revealing the full range of structures within each example, and providing a clearer presentation of the technologies used to create them. On some items, in order to study mechanical technologies and to capture microphotographs, we also created macrosections.

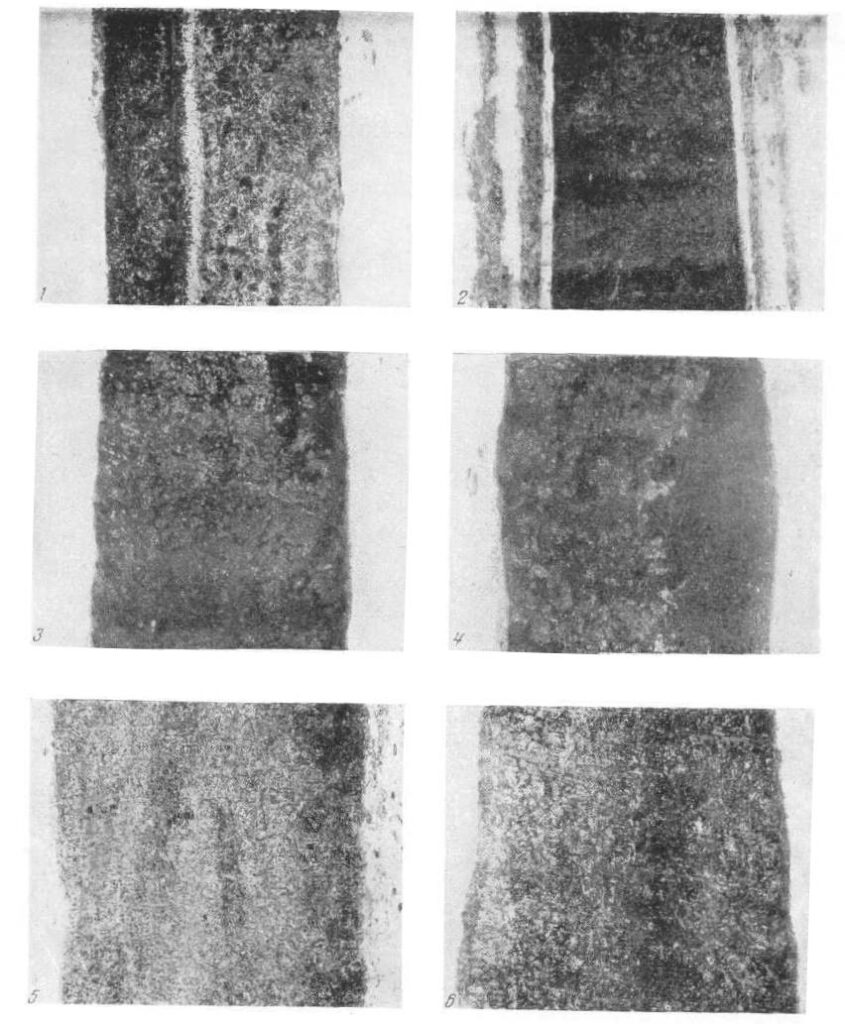

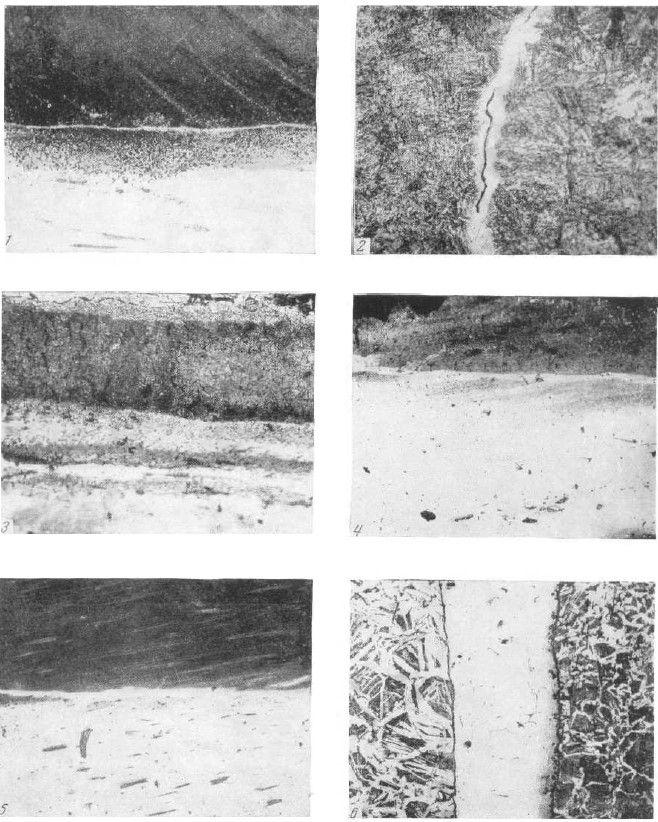

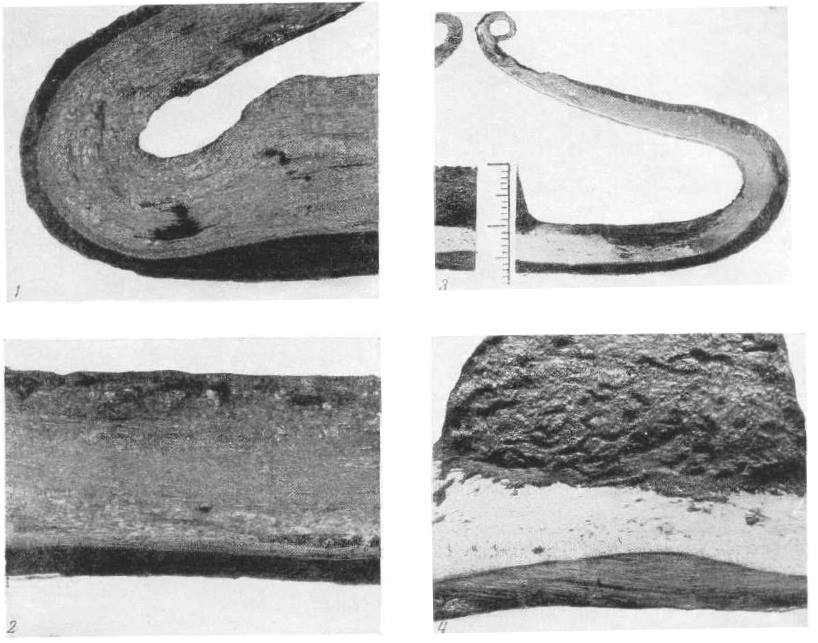

In addition, taking into account the already known typical techniques used for creating this or that item, we used a simplified macrostructural analysis for wider coverage of the studied objects. Macrosections were etched to reveal their macrostructure (on either a cross-section or on the surface of the sample), as well as the whole item in its entirety, without preliminary machining (grinding) of the surface. In this manner, we managed to produce a massive study of the technologies of these medieval items (this analysis was performed on 168 examples), without destroying the items themselves. The reactive agent used for this method of revealing macrostructures was a solution of 25% hydrochloric acid in water. Following the etching, which lasted from 5 minutes to an hour depending on the condition of the item, the surface clearly revealed the structure of ferrite and its carbonaceous alloy (see for example, illus. 25-1). Welding and soldering seams became easily visible. Moreover, the structures of steel zones, depending on heat treatment[4]jeb: that is, quenching and tempering. to which the item was separately subjected, became colored in different shades, ranging from gray to a dark, almost black color. This allowed us to easily reconstruct the technology used to create those items.

For certain structures of iron and steel zones, we measured the hardness and microhardness. This additionally revealed the grade of the iron or steel. This was particularly important for the characterization of steel which had been heat treated.

Part II – Raw iron and steel production in Novgorod

The large quantity of ferrous metal needed for Novgorod’s blacksmithing arts was produced by peasant metallurgists over the vast expanse of the Novgorodian lands. Part of the iron produced by these peasants remained in the countryside for the use of local blacksmiths, but the bulk went to Novgorod’s urban smiths.

Surviving written sources from the late 15th and early 16th centuries reveal a broad picture of the development of peasant iron production in the area along the shore of the Gulf of Finland. Census books from Votskaya Pyatina from 1500 and 1504-1505, which have survived in a far from complete form,[5]Novgorodskie pistsovye knigi (NPK), vol. III; Gnevushev, A.M. Otryvok pistsovoj knigi Votskoj pjatiny vtoroj poloviny 1504-1505 gg. Kiev, 1908. relate that in this small region running from the eastern bank of Luga Bay in a 30-40 km strip, there were more than 204 blast furnaces [Rus. домница, domnitsa] belonging to peasants of the local villages and settlements. Blast furnaces are also mentioned in the region between the Mga River (a tributary of the Neva River) and the Naz’ya River, which flows into Lake Ladoga.

The owners of blast furnaces, and often, a single blast furnace was owned by multiple families, were basically engaged in the production of iron, although they did not break from agricultural activities (the chroniclers rarely call any plots of land unplowed). One supporting fact for this is the large proportion of iron that was paid in their rent. These “blast furnaces,” as the census books call these peasant metallurgists, dug up ore on their own land, that is, on community-owned land, or went to princely or other lands. In the latter case, they would pay “bryazgi,” that is, a rental fee for the right to mine ore. Rent for blast furnaces was paid in iron, or partially in crops.

In order to approximate the annual volume of production of iron in this region over the course of the 15th century, it is sufficient to mention that according to the “old income,” that is, the quitrent before the 1500 census, aside from crops, metallurgists paid for each blast furnace iron in the quantity of around 110 blooms a year.[6]NPK, vol. III, pp. 501, 908, 916, 913, et.al. V.N. Kashin widely studied this topic in his work “Krest’janskaja zhelezodelatel’naja promyshlennost’ na poberezh’e Finskogo zaliva po pistsovym knigam 1500-1505 gg.” Problemy istorii dokapitalisticheskikh obschestv (PIDO). 1934 (4), p. 12. Considering that each blast furnace could produce up to 500 blooms a year (which is realistic even if the oven was loaded only over the 3-4 winter months each year), then the overall production of blast furnaces for the Luga Bay region alone would be around 100,000 blooms a year, or in weight (each bloom weighs around 3 kg) around 20,000 poods of iron a year.[7]jeb: a pood is a medieval Russian measure of weight, equal to about 36 pounds. So, 20,000 poods would be approximately 360 tons of iron.

So far we do not have any data on the level of development of iron-production in the Novgorod region for earlier time periods, but it is undeniable that it was sufficiently developed in order to meet Novgorod’s wide demand for iron, as there were no iron production sites within the city itself.

As is known, iron-production prior to the development of factory metallurgy in the 17th-18th centuries was always an activity done by villagers and rural people in medieval Rus’. This was the result of very many economic and technological facts of metallurgical production itself. The production of icon requires raw materials: ore and wood, both of which were located on common land or land owned by their feudal lord. Production required the participation of a large number of people – to dig up ore, to enrich it, to cut down wood, burning charcoal, and finally, for the metallurgic process itself, which required a minimum of 2-3 people. As a result, blast furnaces were often owned by several neighboring households.[8]See for example NPK, vol. III, p. 912. In addition, metal production was tied to the seasonality of several forms of labor: digging up ore and burning charcoal was done in the summer and fall months, enrichment of ore in the early winter, and the production of iron in blast furnaces in the winter months. All of these conditions predetermined that metallurgic production remained outside the city, the countryside or villages, within the rural community.

The census books from the 1580s in Novgorod also convincingly suggest that there was no urban iron-production: Out of 5465 artisans and merchants living in the city, representing 237 professions, the iron-working arts were represented by 235 artisans (smiths, cutlers, nail makers, locksmiths, arrow makers, needle makers, pin makers, axe makers, brace makers, plow makers, armorers, saber makers, farriers, knife grinders, and steel-makers [Rus. ukladniki]), in addition to 31 iron merchants.[9]Artsikhovskij, A.V. “Novgorodskie remesla.” Novgorodskij istoricheskij sbornik. Iss. 6. Novgorod, 1939, p. 3. Among these, there was not a single blast furnace, and only 4 ukladniki, artisans who enriched iron into steel. All iron-working production in Novgorod was done using imported steel.

The census books from Votskaya Pyatina, while describing the high level of development of rural iron-production in the 15th century, do not provide any evidence of the technique of production. But, we can nevertheless suppose a general picture of this technology. The census books indicate that a blast furnace (domnitsa, the word used by the census books to describe structures which “boiled” iron) consisted of one or two ovens: “one blast furnace consisting of one oven”, or “one blast furnace, consisting of two ovens.”[10]NPK, vol. III, p. 609. Consequently, the blast furnace was not simply a free-standing oven for raw materials, but rather a more complex structure. It is likely that this was a construction consisting of a wooden frame, rectangular or square in shape, inside which there was located either one or two raw material ovens in a typical arrangement. The space inside the frame was filled with earth to the top of the ovens and the top of the frame, forming the upper flat surface. Small notches were cut through the walls of the frame leading to the chest of the oven, through which air was blown, and which was used to remove completed iron blooms. Similar blast furnaces with one, two or even four ovens are known from written sources from the 17th-20th centuries.[11]For example, a Yakutsk blast furnace from the 20th century, cf. Gajduk, A.A. “Proizvodstvo syrodutnogo zheleza v Jakutskom okruge.” Zhurnal Russkogo metallurgicheskogo obschestva. St. Petersburg, 1911, p. 293; Strelov, E.D. “K voprosu ob ekspluatatsii zalezhej rud po rr. Batome i Ljutenge.” Kozjajstvo Jakutin. 1928 (1), p. 55.

The construction of ovens used by metallurgists in the Gulf of Finland shore region in earlier times are also known to use from the archeological record. In 1948, the author of the current article carried out archeological explorations in this region. Near the village of Starodvor’e on the Kovasha River (in the Lomonosov region of the Leningrad district), on the so-called Progonny Field, located on the other side of the river, we discovered a raw-material blast furnace. Ceramics found along with the oven allowed us to date it to the 12th-13th centuries.

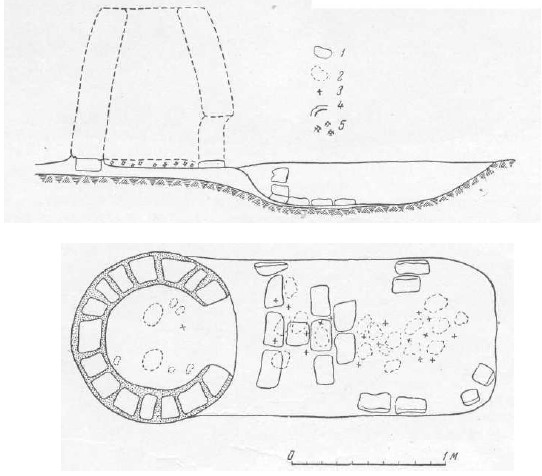

1-Sandstone slabs; 2-Slag; 3-Fragments of nozzles; 4-Clay coating;

5-Charcoal

In one of the pits on Progonny Field, we discovered the clay base of a round oven, with walls about 10 cm thick, lying directly on the ground. Only one row of flat sandstone slabs survived from the walls of the furnace (illustration 1). The walls were coated with clay. The outer diameter of the oven was around 1.1 m, and the inner diameter was around 0.7 m. There were no slabs on one side of the ring of furnace walls; as it turned out later from the clay pavement, this was the location of the furnace belly. In front of the oven there was a small notch , about 1 m wide, 1.75 m long and 0.3 m deep (based on the level of the furnace bottom). The bottom of this notch was covered by about 20 slabs of sandstone. The notch was paved with these slabs (about 3-4 cm thick). Inside the oven and in the pre-hearth notch, a multitude of slag, charcoal, burnt clay coating and nozzle fragments. There was approximately 30 kg of slag. Ingots of slag were found up to 1.45 kg in weight. More than 30 nozzle fragments were discovered.[12]Kolchin, B.A. Otchet ob arkheologicheskikh razvedkakh na poberezh’e Finskogo zaliva v 1948 g. Rukopis. Nauchnyj arkhiv IIMK, D. No. 455.

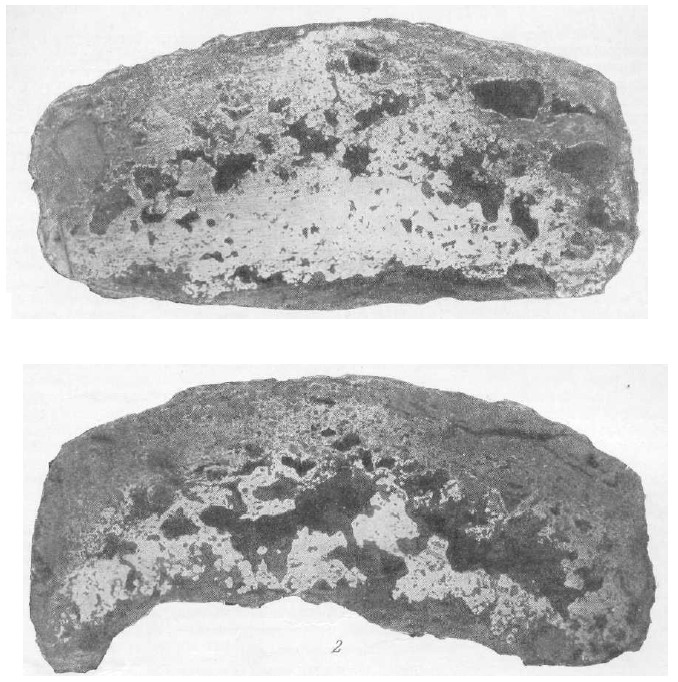

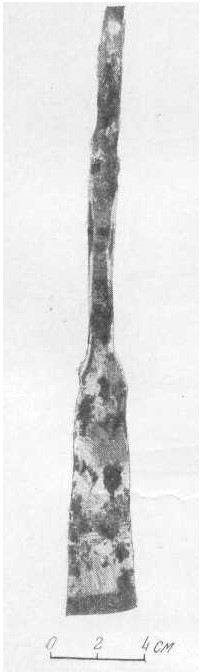

Iron was supplied in Novgorod in the form of commodity blooms. Three such blooms were found in the Nerevsky dig, in a layer from the 13th century (13-6-386, 11-6-255 and 10-8-519). They had a flat, pancake-like shape, slightly convex, around 140 mm in diameter and 60 mm thick. Their weight was approximately the same: sample 13-8-386 weighed 2760 g, 11-6-255 weighed 2650 g, and 10-8-419 weighed 2920 g.

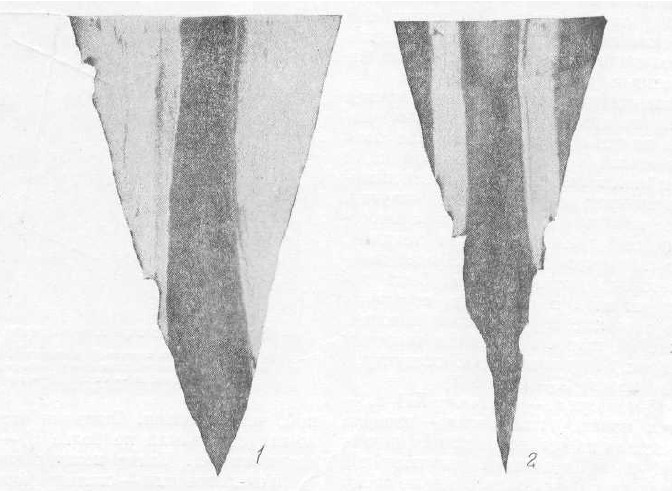

1-late 13th century bloom (10-8-519); 2-13th century bloom (11-6-255)

white: ferrite; light grey: ferrite with slag inclusions; dark grey: voids.

We subjected two blooms (11-6-255, 10-8-519) to macrostructural and microstructural analysis. The cut for the cross-sections was done along the diameter of the bloom. Both cross-sections revealed extremely variegated, spongy structures (illustration 2). In addition to metal (ferrite), these blooms contained large quantities of slag inclusions and voids; in bloom 10-8-519, we even discovered inclusions of charcoal. The metal in these blooms would have required additional purification prior to being forged into any goods.

Microstructural analysis of the metal in these blooms revealed the typical structure of ferrite (illustration 14, 1). Grains measured from a 3 to a 6 on the grain size scale. By carbon content, the ferrite was relatively pure; there were almost no perlite (carbonaceous) areas in the ferrite field. The hardness of the ferrite in the studied blooms measured 40 units on the Rockwell scale (scale V). As such, the macrostructural analysis of these blooms revealed that iron arrived in Novgorod in a relatively raw form. It would have been necessary to process these iron blooms into semi-finished product (rods or plates), to remove the slag, and to cook the metal into flatter, more monolithic pieces. This work was done by Novgorodian smiths.

In order to determine the quality of the steel which Novgorodian smiths used for their items, we mass annealed steel items which, as a rule, were always found in a heat processed state. 37 microsections were annealed. After being annealed, these samples always revealed a structure of ferrite with perlite, containing various quantities of carbon.

The study of annealed structures revealed that the selection of steel in terms of carbon content was determined by the intended prepared item. Even as early as the 10th-11th centuries, Novgorodian smiths strongly distinguished steel based on its carbon content and selected high- or medium-carbon steel in direct relation to the technical conditions for preparing instruments, tools, etc.

The quality of steel was distinctly high. It was relatively free of non-metallic inclusions. Slag was always lower in quantity than in high-quality iron. The steel was also distinctly homogenous in terms of the distribution of carbon into the ferrite. But, if the quality of steel is studied chronologically, by century, then we note that the purest steel was used in the 11th century and occasionally in the 12th century. By the late 12th and the 13th centuries (and in particular by the second half of the 13th century), the quality of steel fell somewhat; we find larger slag inclusions, as well as occasional variation in the carbon content. The quality of steel did not improve in the 14th century, and in the 15th century it even fell slightly further. We shall discuss the reasons for this decline in the quality of steel production below.

As we have already said, pig iron was reworked into steel by specialists, called ukladniki, who worked in Novgorod itself. Archeologically-speaking, little is known about the technology used to produce steel. This ancient and rather complex process has to date escaped the notice of archeologists. In relation to this, let us review further several finds uncovered in the Nerevsky dig.

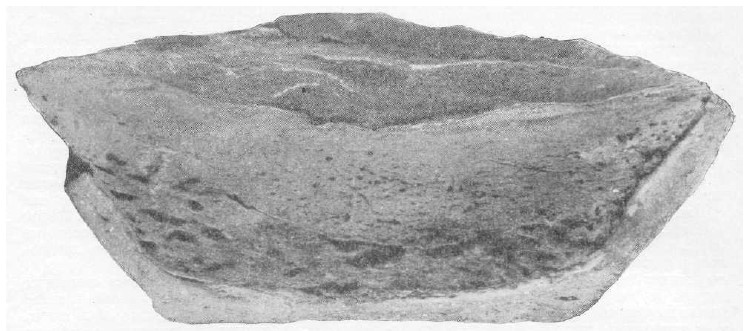

Among the small quantity of iron slags collected in the Nerevsky excavation (in total, 37 finds found in 1951-1955, of which each was either a piece of slag or an accumulation of such pieces) there were 4 finds, typically joined by archeologists into a single group with the other slag but which were distinctly different. These finds were a sintered solid mass covered by a plaque of dark blue oxidation. Two such pieces were shaped like the bottom of an ordinary clay pot (25-24-517, 10-15-186), and in two cases, the pieces were still located in clay pots, occupying the entire lower area of their vessels (18-19-297, 5-10-1125). Similar archeological finds are known from other medieval Russian cities, including Moscow[13]Rabinovich, M.G. “Raskopki v Moskve v 1950 g.” KSIIMK, 1952 (44), p. 117. and Staraya Ryazan’.[14]Mansurov, A.A. “Drevnerusskie zhilischa.” IZ. 1941 (12), p. 85. Many similar finds, that is, found together with clay vessels, have been collected from among the Volga Bulgars.[15]Efimova, A.M. “Metallurgicheskie gorny v gorode Bolgare.” KSIIMK. 1951 (38), p. 129. Structural analysis revealed that the mass filling the lower portion of the vessel consisted of a fine, sifted, yellow or grey sand, which was strongly burned and in some locations somewhat impregnated with slag (illustration 3). The surface of the sand was more heavily infiltrated with slag and looked like a sort of thin crust that was, as we have already stated, dark blue in color. There were no fine crystals of metal (ferrite), as are commonly found in slag. On the surface of the sand and around the walls of the vessel in several places, there were small clusters of charcoal.

Spectral analysis for the formation of impurities discovered that, in addition to the typical impurities found in Novgorod sand and clay, there was a “high” concentration of sodium.

From the description above, one thing is indisputable: some sand was poured into these pots before some kind of production operation, creating a mound at the bottom of the vessel; in the sample reviewed above, this layer was found 30-36 mm deep. In addition, we know that the vessel also contained charcoal and ferrous metal. Most likely, similar vessels were used as crucibles for carbonizing iron during the creation of steel. Charcoal was used as the carburizing agent (carburizer). In order to activate this process of carburization, it appears that sodium chloride was added to the coal, as can be seen from the presence of high levels of sodium in the composition of the pot’s sand layer. It should be noted that in modern carburization, among numerous compositions used as carburizers, we still use charcoal, sodium chloride and potash.

This method for producing carburized steel or “tomlyonki”, judging by the data obtained by our metallographic analysis of steel items, was widespread in Novgorod, but not the only method in use. Structural analysis of the metal from many steel blades created through carburization also revealed structures of welded steel produced by ukladniki in typical smithy forges.[16]On the technology for creating welded steel, cf. Kolchin, Chernaja metallurgija… p. 51, et.al. As I have already noted, however, he primary method used by Novgorodian smiths to create steel for tools, instruments, etc. was carburization.

To conclude our review of the metallurgy of iron and steel, let us review the results of spectral analysis of the metal in the Novgorod finds (table 1). It is known that marsh and field iron ores, which belong to the group of exogenous formations, during their formation often concentrate along with base metal oxides; for example, iron forms with a small number of oxides of other metals: molybdenum, nickel, vanadium, cobalt, titanium, chromium, etc. The conditions for the formation of these oxides are the same as for iron. Any of these metals found in the ore along with the iron are reduced simultaneously in the blast furnace, and pass into the iron bloom and further remains in its final composition. As such, the existence of admixtures in the iron of this or that metal or alloy allows us to classify the iron based on the areas of distribution of these metals. When the geographic allocation of these alloys becomes known (for example, in Eastern Europe), we are able to easily localize the iron ore deposits that were used to create a given item. These studies have already begun on a wide scale in the Soviet Union.[17]This work is being performed by the Laboratory for Structural and Spectral Analysis of the Chair of Archeology for the Department of History at Moscow State University and in the Laboratory for Spectral Analysis of the Institute for the History of Material Culture. Recently, as a result of mass spectral studies of ores and metals, it has been possible to obtain initial data to compile maps of the geographical distribution of iron ores and metals. Similar work is also underway for non-ferrous metals.

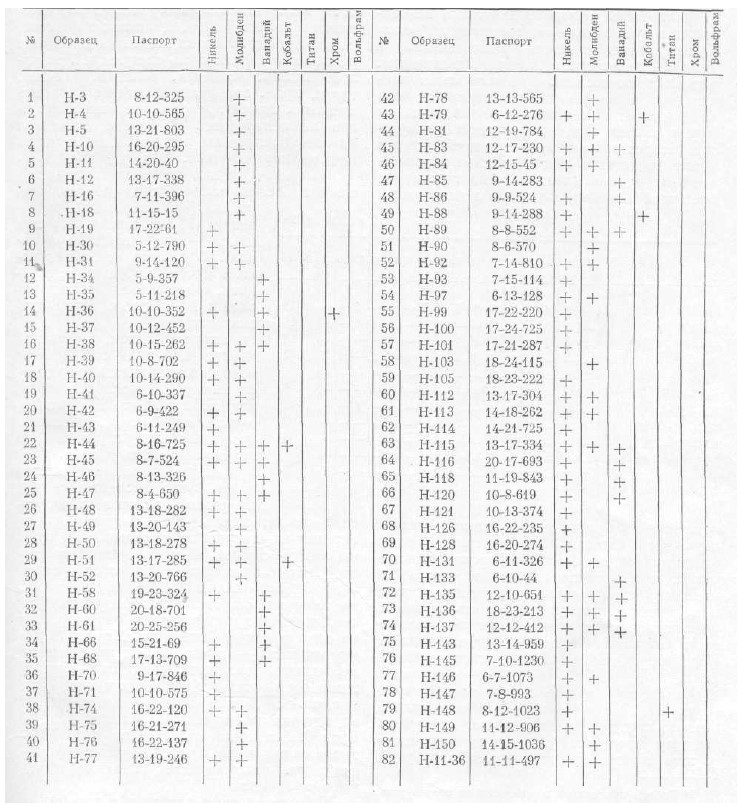

[jeb: translations: Образец-Sample; Паспорт-Passport/certificate; Никель-Nickel (Ni); Молибден-Molybdenum (Mo); Ванадий-Vanadium (V); Кобальт-Cobalt (Co); Титан-Titanium (Ti); Хром-Chromium (Cr); Вольфрам-Tungsten (W)]

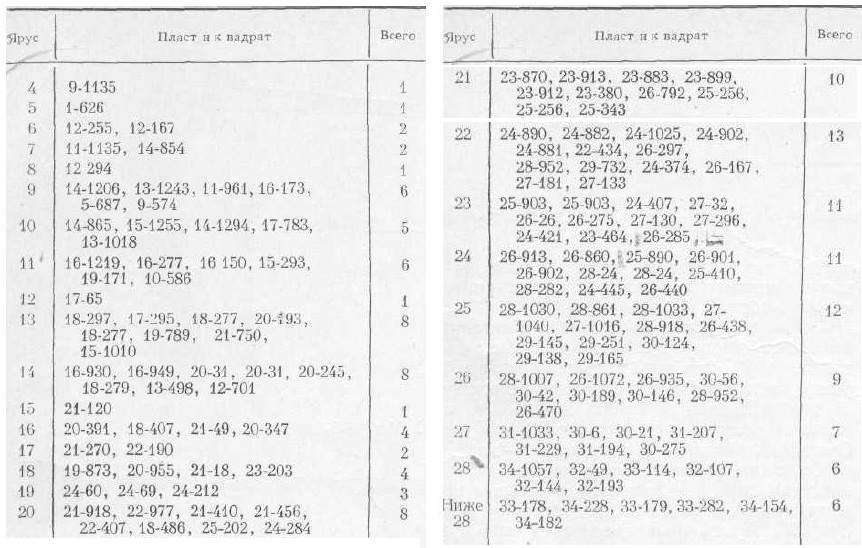

As evidence of our primary attempts, we are publishing the results of our spectral qualitative analysis of the iron in Novgorodian knives.[18]This analysis was carried out by Ju.L. Schapova and A.N. Repin in the Laboratory for Structural and Spectral Analysis of the Chair of Archeology for the Department of History at Moscow State University. The analysis was performed on the butts of knives which had welded steel blades (107 knives from 12th-15th century layers). Qualitative analysis was performed on 36 elements accepted in the practice of spectrography. For our purposes, we selected the following 7 metals from those elements: nickel, molybdenum, vanadium, cobalt, titanium, chromium, and tungsten. The steel of 25 examples did not contain any of these elements. The steel of the remaining 82 knives contained admixtures of these metals, or mixtures thereof (table 1).

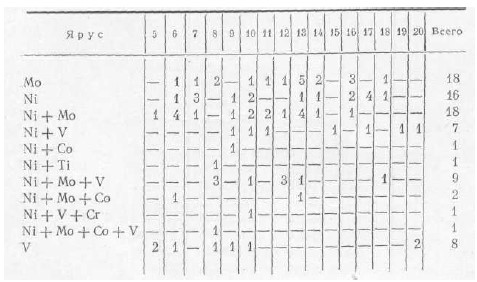

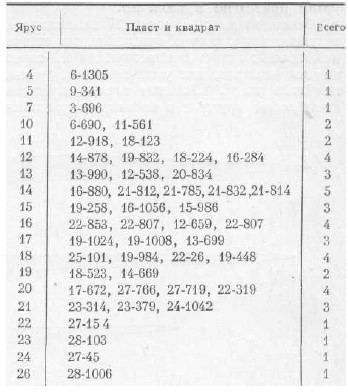

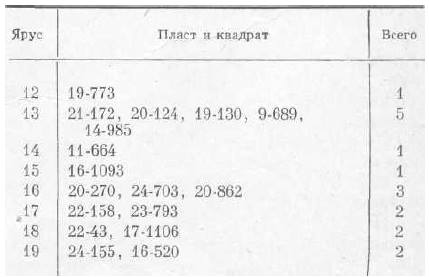

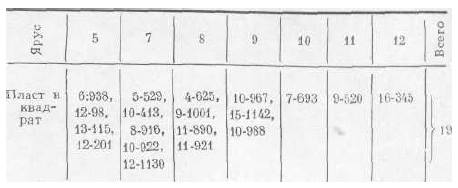

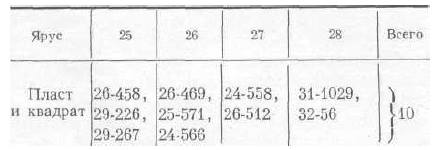

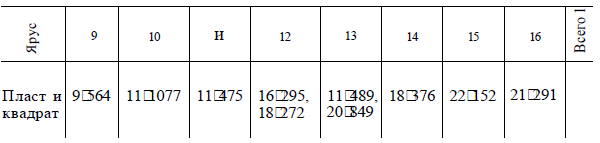

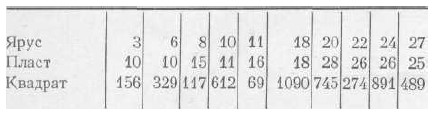

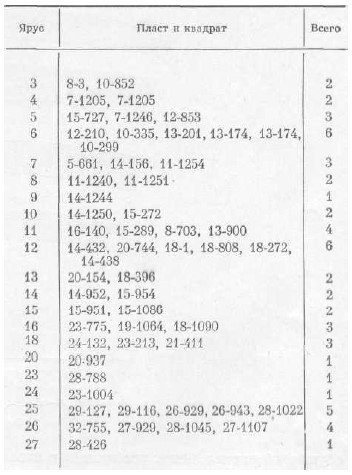

Based on table 1, we can see that the principle admixtures in the iron of Novgorod knives was nickel (16 samples), molybdenum (18 examples), or a nickel-molybdenum alloy (18 examples). The iron of the remaining knives, aside from 8 examples which contained vanadium, contained admixtures of nickel and molybdenum with a series of other metals. As such, the base character of admixtures to iron in the Novgorod items was nickel and molybdenum. These were found in 74 out of 82 samples which contained admixtures. The distribution of these samples by layer (time period) is shown in table 2.

[jeb: translations: Ярус-Layer; Всего-Total]

The next step of our work will be a study of the ores from various locations in the Novgorod region; then, by outlining the areas of various admixtures in works and ore, we will be able to determine from which location a given set of iron was brought to Novgorod. But, for now, by analyzing the table of admixtures, we note the absence of chromium and titanium in Novgorod item items (they are found only once each in items from the 14th century). We know that (albeit from a relatively small number of samples analyzed) chromium and titanium were found relatively frequently as admixtures in iron items produced in the central and southern regions of medieval Rus’.[19]Kolchin, Chernaya metallurgija… This strengthens our theory stated above about the local metallurgical basis for Novgorodian ironworking arts.

Moreover, we performed spectral qualitative analysis on the iron from 12 items from the lower reaches (7th-8th centuries) of Staraya Ladoga. This analysis revealed the same 36 elements. In the iron from 5 items, no admixtures of the elements listed above were found. The remaining 7 items contained molybdenum, 3 of which also contained cobalt. This data sufficiently supports our observation about the local use of iron with admixtures of molybdenum and nickel in the Novgorod region.

Part III – Construction, Typology, Chronology, Technology

The construction, typology, chronology, and technology of production of iron and steel items will be studied by sections in the order of the aforementioned nomenclature. The current work excludes items classified as weapons or horse tackle. These will be be broadly covered by A.F. Medvedev’s article “The Weapons of Novgorod the Great”, published in this same volume.[20]Medvedev, A.F. “Oruzhie Novgoroda Velikogo.” Trudy Novgorodskoj arkheologicheskoj ekspeditsii, Tom II. Materialy i Issledovanija po Arkheologii SSSR, No. 65. 1959 (2), pp. 121-191.

Metalworking Tools

We mentioned above that numerous items of steel, iron, and non-ferrous metals found in the Nerevsky Excavation were created by Novgorod’s smiths, jewellers, and other artisans who worked with metal. In the technical organization of metalworking production, tools which were used by these masters in their work play a significant role. Several data for the characterization of tools belonging to Novgorod’s smiths and jewellers can also be extracted from these materials found in the Nerevsky End.

At different sites in the excavation, from early and later layers, more than 30 examples were collected of various tools used in the metalworking arts. The sphere of metalworking and locksmithing tools included blacksmith tongs, blacksmith hammers, files, pritchels, and nail headers. Jeweler’s tools included anvils, jeweler’s hammers, tongs, a chisel, and tweezers (forceps). Steeler’s tools included crucible tongs [Rus. кричные клещи, krichnye kleschi, “bloom tongs”]. Several items were discovered in the locations of ruined workshops (for example, the jeweler’s hammer 20-29-738, or the smith’s hammer used by a jeweler, 12-17-66), but the majority of items were discovered among various household and everyday inventory in ruined dwellings or in the area of various manor courtyards. We will describe each item in detail, following the order listed above.

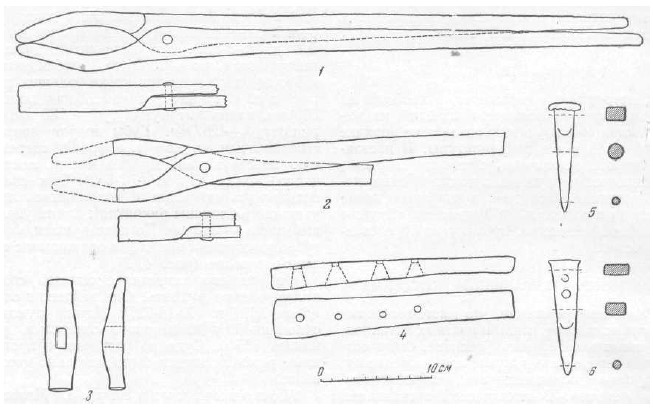

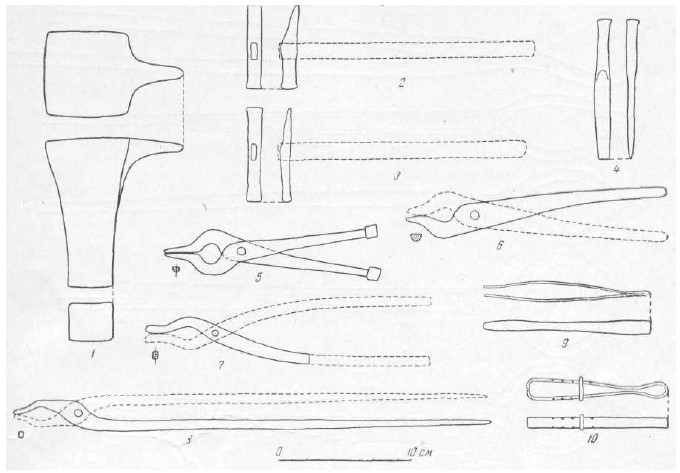

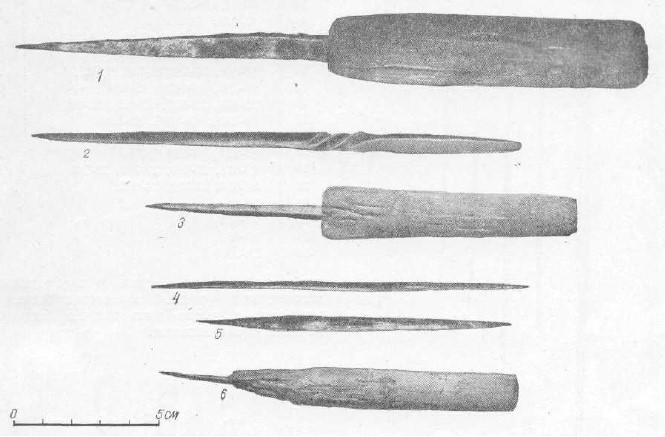

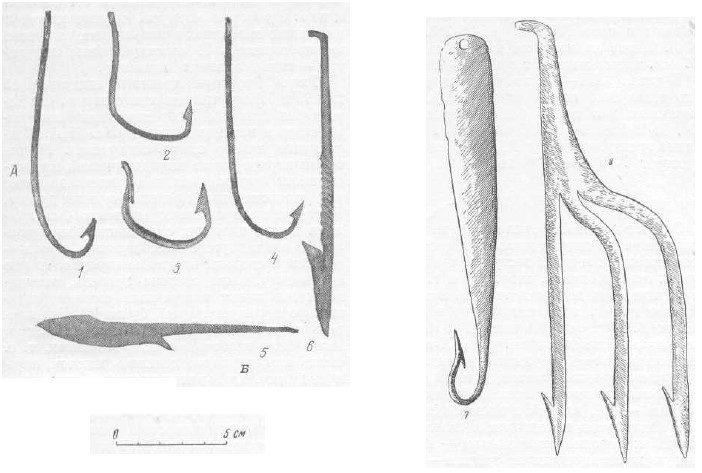

1-tongs, 15th cent. (5-8-392); 2-tongs, late 14th cent. (6-7-532); 3-hammer head, 13th cent. (10-13-1299); 4-nail header, late 14th cent. (6-7-928); 5-pritchel, 14th cent. (8-8-1064); 6-pritchel, late 14th cent. (6-8-896)

Smith’s tongs [Rus. кузнечные клещи, kuznechnye kleschi]

Three examples of these were found. One well-preserved pair was found in a layer from teh early 15th century (5-8-392). This massive, heavy tool (weighing 1350 g) was intended for holding large items during forging (illustration 4, 1). It was 550 mm long, with elongated heads that were 130 mm long. The width of head was 25 mm. The heads have a hinge with articulated steps (that is, a completely modern construction). Other tongs were found in a 14th century layer (6-7-532). They were severely corroded and are only partially preserved (the handles have broken off). The surviving part is 340 mm long. In their construction, form of the heads, and proportions, these tongs are identical to those described above (illustration 4, 2).

From the third example, only the handles survive. They were found in a layer from the late 13th century (10-18-737). The length of these handles, which broke off near the hinge hole, is around 365 mm. Judging by the size and proportions of these handles, the tongs must have been decidedly massive.

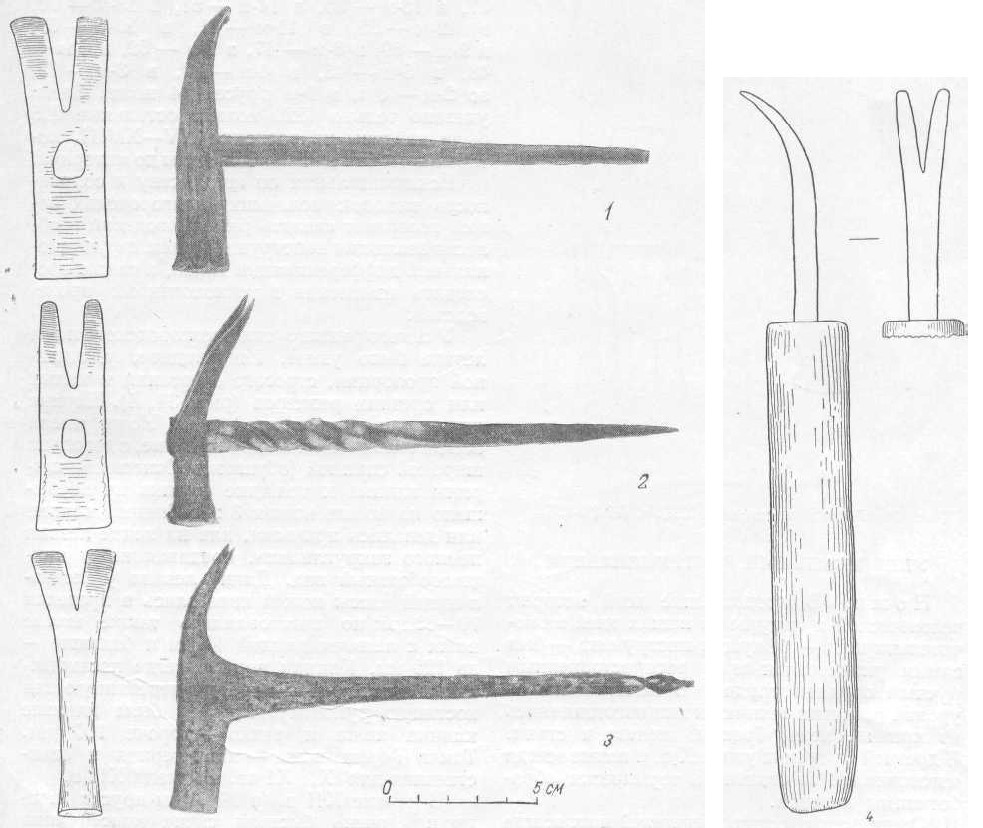

Smith’s hammers [Rus. молотка кузнечная, molotka kuznechnaja]

These hammers were used in blacksmith, locksmith, or sometimes jewelry workshops. Of these, 2 examples have been found. In terms of their construction and the weight of the iron hammer heads, these belong to the type of bench hammers. The form of these hammers can be clearly seen from illustration 4, 3. A hammer found in a layer from the late 13th century (10-3-299) had a head 102 mm long, a striking surface 20 x 15 mm, a blade 20.5 mm wide with a curve radius of 5 mm; the opening for a wooden handle was 18 x 8 mm, and the head weighed 210 g. A second hammer found in a layer from the mid-13th century (12-17-66) had a head 100 mm long, a striking surface measuring 25 x 20 mm, and a blade width of 25 mm. The oval, elongated hole for the handle was 27 x 7 mm, and the head weighed 290 g.

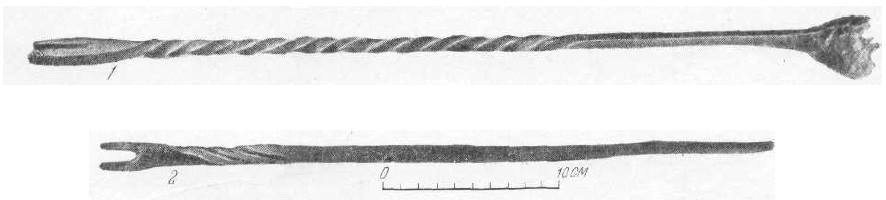

Files [Rus. напильник, napil’nik]

In the excavation, four files were discovered: 2 intended for use on metal, and 2 for use on bone, leather or wood.

A small metal file was found in a 10th century layer (27-30-1011). Its overall length was 115 mm, and length of the blade was 83 mm. The file was rectangular in cross section, 7.5 x 4.5 mm at the tang and 5.6 x 3.6 mm at the end. The hatching was simple and single cut, with the teeth perpendicular to the longitudinal axis. The tooth interval[21]jeb: the term used here, шаг зуба / shag zuba, literally translates as “tooth pitch”, which is measured as the number of teeth per 1 inch/25.4 mm. The author appears to actually mean tooth interval, the distance from one tooth point to the next tooth point. I have translated accordingly. was 1 mm. The notches were hand-cut, but are very even and regular. All four surfaces were notched (illustration 5, 1).

The other file was found in a layer from the 14th century (7-8-928). The overall length was 194 mm, and the blade was 134 mm long. The cross-section of the blade was rectangular, 15 x 4 mm at the tang and 12.5 x 3 mm. The hatching was simple. On the wide sides of the file, it was triple cut in a herringbone pattern; the thin sides were single cut. On average, the tooth interval was around 0.6 mm. The notches were hand-cut and are uneven.

1-10th cent. (27-30-1011); 2-14th cent. (7-8-928); 3-14th cent. (9-15-789); 4-14th cent. (7-11-1138)

Both files were subjected to microstructural analysis. The samples were taken as cross-sections of the blade at 20 mm (for file 27-30-1011) and 10 mm (for file 7-8-928). The microsection of file 27-30-1011 was found to be a homogenous martensitic structure. The martensite was large-needled. The metal hardness fluctuated from 62-65 units on the Rockwell scale (scale C). As such, we have before us an all-steel file which has been heat treated. The microsection for the other file revealed the following structure. The file blade was made up of 3 zones, that is, of 3 stripes of steel, fused together. The welding seams were thin and straight. The structural condition of the metal was martensite with troostite, that is, the file was heat treated. The hardness of the two bands on the edges, which were notched, ranged from 59 to 60 units on the Rockwell scale (scale C). Annealing the sample revealed that these edge bands were made of good carbon steel, with a carbon content around 0.8%.

The bone file was found in a layer from the 14th century (9-15-789). The overall length was 180 mm, with the blade 106 mm long. The slightly curved blade was rectangular in cross-section, 8 x 5 mm in size. The hatching was large and single-cut (illustration 5, 5). The tooth interval ranged from 4.5-5 mm.

The other, larger file for working bone and leather was a rasp (illustration 5, 4), also found in a 14th century layer (7-11-1138). It was overall 245 mm in length, with the blade 185 mm long. The cross-section of the blade was rectangular, 23 x 11.5 mm at the tang and 19 x 10 mm at the end. The hatching was only on the broad sides of the blade, in the form of small teeth at a 2.5-3 mm interval. Particles of the processed material would have been cut off by the forward motion of the file.

Pritchels [Rus. бородок, borodok]

In blacksmithing, a tool called a pritchel is used to make a hole in a product. Two such tools have been discovered in Novgorod. A pritchel from a 14th century layer (8-8-1064) was in the form of a round rod with a wide, rectangular butt (measuring 18 x 12 mm) and a pointed end (illustration 4, 5). The pritchel was 100 mm long, and 3.5 mm in diameter at the pointed end (the working end, which is used to punch the hole into heated metal). The rod widened conically to a diameter of 15 mm. Cross-sectional analysis showed that the last 25 mm of the working end had a steel structure.

The other pritchel, found in a layer from the late 14th century (6-8-896), had the same kind of working end (illustration 4, 6). The pritchel was 106 mm long; it’s rot had a rectangular cross-section, measuring (at the butt) 25×11 mm. The shape of the working end was the same as that on the previous pritchel, and was cone-shaped with a truncated top that was around 2.5 mm in diameter. Around the butt on the wide side of the rod there were 2 holes, 6 mm and 8 mm in diameter. This part of the tool was mostly likely used as supports when hammering holes into a product using another pritchel. Similar stands were used to control the passage of the pritchel into the punched metal.

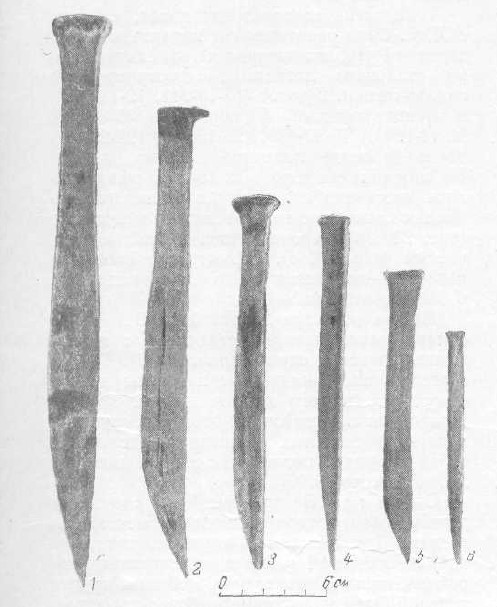

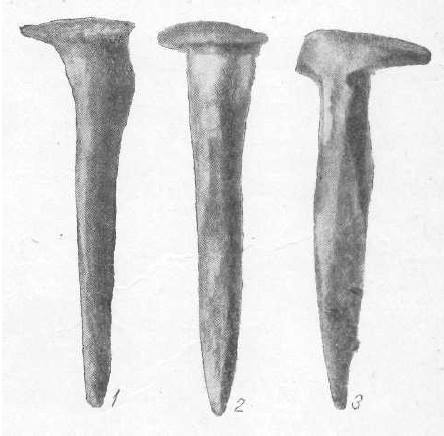

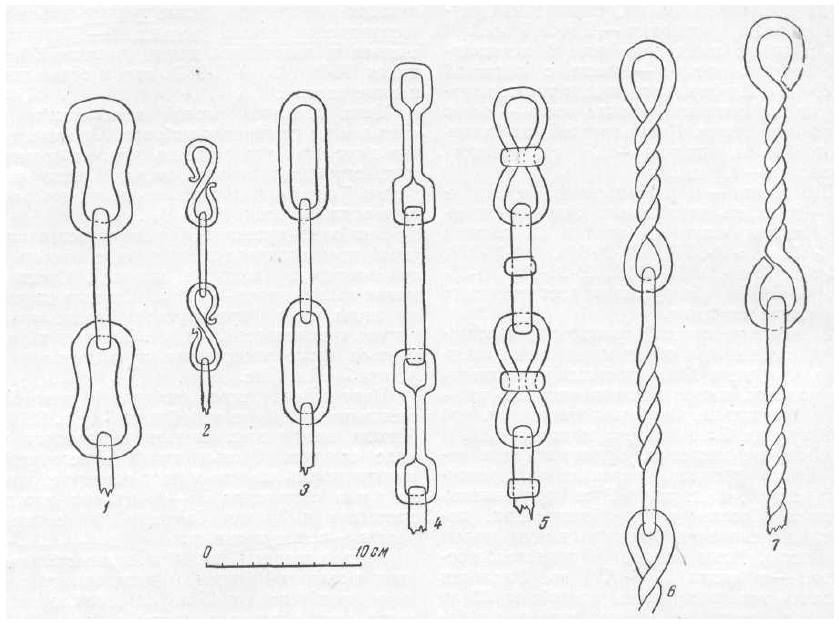

Nail header [Rus. гвоздильня, gvozdil’nja]

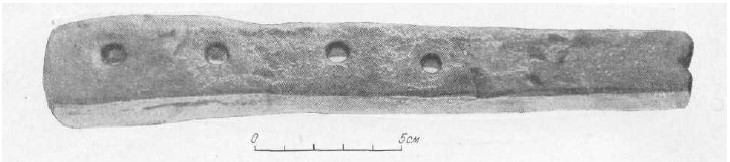

A specialized tool used by nail makers was a massive block of iron with several perforating holes through it, used to forge the heads of nails and rivets (illustration 4, 4; illustration 6). One nail header was found as a solitary example, in a layer from the late 14th century (6-7-928). This sample (215 mm in length) was rectangular in cross-section, measuring 34 x 19 mm at the working end and 26 x 15 mm at the handle. The item weighed 730 g. At one end of the block there were four holes, located around 30-40 mm apart one after another. The hole arrangement was as follows: on the face side of the block, they had a regular round form, preserved to a depth of 3 mm. Afterwards, the holes sharply widened, forming a funnel-shaped recess. The diameter of the holes on the face measured 5.2, 6.2, 6.1 and 7.2 mm, but judging by the worn edges of the holes, two of them (5.2 and 6.2 mm) were originally 4 and 5 mm in diameter. As such, this nail header was adapted for the forging of nail heads 4, 5, 6 and 7 mm in diameter. The funnel shaped holes were necessary and determined by the technology at hand. The holes were made such that the body of the nail or rivet did not become stuck in the long channel (and its length was determined by the thickness of the block, which in turn was tied to the size of the nail header, such that the thicker the nails, the more massive the block needed to be). It is worth noting that in modern artisanal nail making, nail headers of exactly the same shape are still in use.[22]jeb: To clarify a bit on the use of this header, stock rod would be forged into a conical or tapered shape, such that when inserted into the hole on a nail header, the nail body was able to pass through the hole, but when the taper reached the size of the hole, the rod could be inserted no further. The rod would be cut a short distance above the hole, reheated in the forge, and then reinserted into the nail header. By hammering the hot iron over the nail header’s hole, this end of the nail would become flattened out into the head of the nail. The funnel shape on the underside of the header helped to prevent the nail from becoming stuck in the header, and made it easier to remove the finished nail.

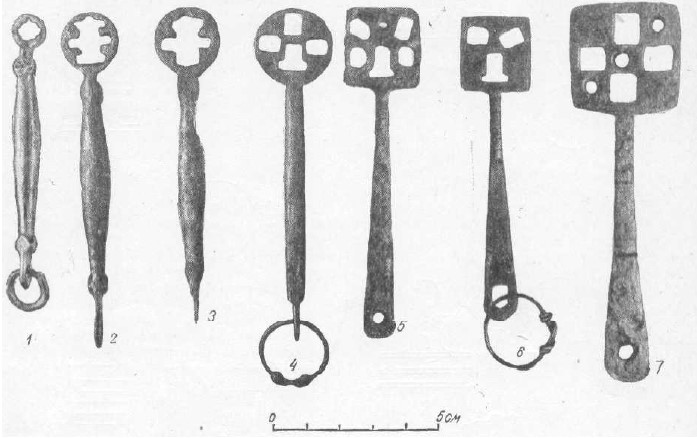

Jeweler’s anvil [Rus. наковальня ювелирная, nakoval’nja juvelirnaja]

For the first time among Russian antiquities, a jeweler’s anvil with a horn (18-25-725) was discovered in a 12th century layer. In form and size, it is reminiscent of a typical jeweler’s anvil as are frequently encountered by archeologists, but unlike those, it has an elongated horn on one side (illustration 7, 1). Similar anvils were most convenient and universally used in the mechanical technology of jewelry production. The elongated horn allowed the production of, aside from normal forging, all kinds of curled works. The dimensions of the anvil were as follows: 112 mm in height, 103 mm in length for the working surface along with the horn, 64 mm in width, and the horn was 36 mm in length. The cross-section of the anvil was rectangular with rounded edges, 19 x 16 mm in size. The size of the lower part, where the anvil was inserted into a wooden block, was 34 x 29 mm. The anvil weights 1460 g.

Jeweler’s hammers [Rus. ювелирная молоточка, juvelirnaja molotochka]

Two jeweler’s hammers were technologically very similar to the jeweler’s anvil. Both were found in a layer from the 11th century. The first hammer (20-29-738) has a strait, very rational form and weighs 33 g (illustration 7, 2). We incidentally note that it is absolutely analogous to modern so-called watchmaker’s hammers. The hammer has a flat head on one side, and on the other, a rear claw [Rus. задок остряк, zadok ostrjak, “rear ramp”] (that is, a wedge-shaped rounded point). In the center there is a hole with elongated jaws for the wooden handle. The hammer is 61 mm long, the claw is 9.5 mm wide, the head is 11 x 9.5 mm, and the oval hole for the handle is 14 x 4.5 mm.

The second hammer (23-22-611) is of the same construction, but is somewhat elongated and is simpler in form (illustration 7, 3). This hammer is 70 mm long, with a flat head 13 x 7 mm, a claw that is 11 mm wide, and the small hole for the handle is 10 x 6 mm. This hammer weighs 34 g.

1-12th cent. anvil (18-25-725); 2-hammer, late 11th cent. (20-29-738); 3-hammer, 11th cent. (23-22-611); 4-chisel, 11th cent. (22-24-876); 5-pliers, late 15th cent. (3-4-525); 6-pliers, 14th cent. (7-11-1128); 7-tongs, 11th cent. (25-24-522); 8-tongs, 11th cent. (23-23-955); 9-tweezers, type A, 12th cent. (18-20-1049); 10-tweezers, type B, 12th cent. (16-19-866).

Jeweler’s pliers/tongs [Rus. ювелирные клещи, juvelirnye kleschi]

When working in the forge with molten or heated metal, a jeweler (or in general, any artisan working in metal) would need to use small hand-held tongs or pliers. Several examples of these tongs were found in layers from the 11th, 14th, and 15th centuries. Only the tongs from the 3rd layer were completely preserved, the remainder survived only as halves or broken handles and jaws. Even these partial items allow us to restore the complete construction and form of jeweler’s tongs. In an 11th century layer, one half of a pair of tongs (23-23-955; illustration 7, 8) was found. These tongs were 357 mm in overall length, with jaws that were 49 mm long. The construction of these tongs was of a lightweight type; the thickness of the head and handles did not exceed 2.6 mm. The ends of these handles, which were tapered and specially worked, were covered with wood. In an 11th century layer, one more half of a pair of tongs was found (25-24-522). These tongs, which were also lightweight, were around 200 mm long (part of the handles has been broken off). The jaws were 55 mm long, and their width was 3 mm at most (illustration 7, 7).

A larger pair of pliers (illustration 7, 6) was found in a 14th century layer (7-11-1128). This pair was also only partially preserved. It was 195 mm long, with jaws around 52 mm long. The tapered jaws were 4 mm wide and were very tightly fitted one atop the other, achieved via a tight curve near the hinge on each jaw. As a whole, this was constructed very similarly to the next set (illustration 7, 5), found in a layer from the late 15th century (3-4-525). This set is 162 mm long, with jaws 57 mm long. The gripping part of the jaws are more elongated in this pair. The pointed jaws, similar to modern round-nose pliers, are 22 mm long. The width of the jaws averages 6 mm. Part of the handles of a pair of pliers was found in an 11th century layer (22-22-472). This handle was broken off near the articulation hole. It is 265 mm long. Most likely, the original set was 315-325 mm long.

It is worth noting that pliers 7-11-1128 and 3-4-525 (illustration 7, 5 and 6) could have been used by a smith while working on very small items.

Jeweler’s chisel [Rus. зубило ювелирное, zubilo juvelirnoe]

A small chisel was found in a layer from the 11th century (22-24-876). This round rod (8 mm in diameter) had a flat head for hammering on one end, and at the other end, a flat blade ending in a cutting edge (illustration 7, 4). The overall length was 105 mm, with a 7 mm wide blade. The blade of this chisel has survived in a very worn state; the steel weld has been completely ground off.

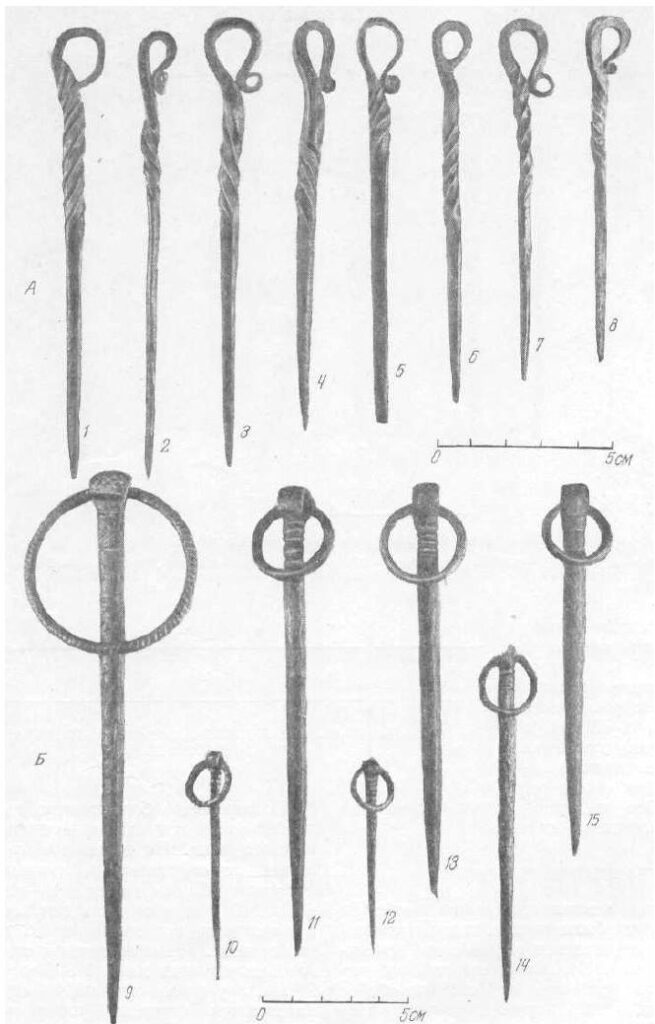

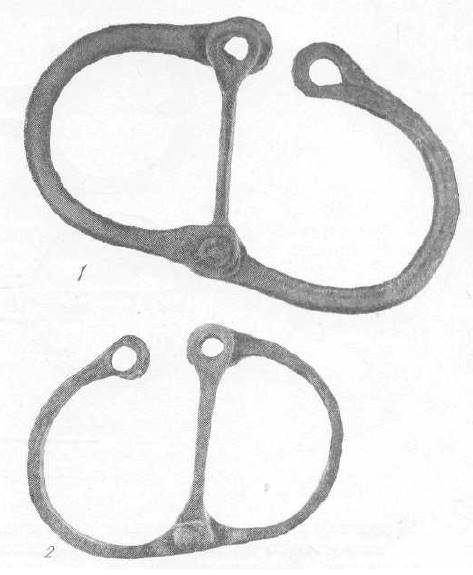

Tweezers [Rus. пинцеты, pintsety, or щипчики, schipchiki]

This tool is used for grasping or holding various kinds of items. In medieval Rus’, the tweezers which we are publishing were widely used by jewelers and artisans in general who worked with non-ferrous metals (the creation of filigree, cloisonné, etc.). Tweezers consist of two elongated arms which have a springy fastening at one end (most frequently, they are made from one rod which has been bent in half) and surfaces made for gripping at the other. Based on the form of the gripping end, tweezers are divided into two groups: ones with flat (parallel) tips, and ones which have Г-shaped (perpendicular) tips. The second type always have a so-called locking ring used for clamping an item in the tweezers.

In the Nerevsky dig, 15 sets of tweezers have been found, of which 8 were of the first type, and 7 were of the second. The construction of the first type of tweezers is very simple; their construction can clearly be seen from illustration 7, 9. These tweezers differed in terms of size, from large (120 mm long) to small (60 mm long). The were found in layers from the 10th-14th centuries (26-20-689, 23-22-503, 18-20-1049, 16-21-252, 12-17-364, 11-16-4, 7-10-868, and 16-22-73).

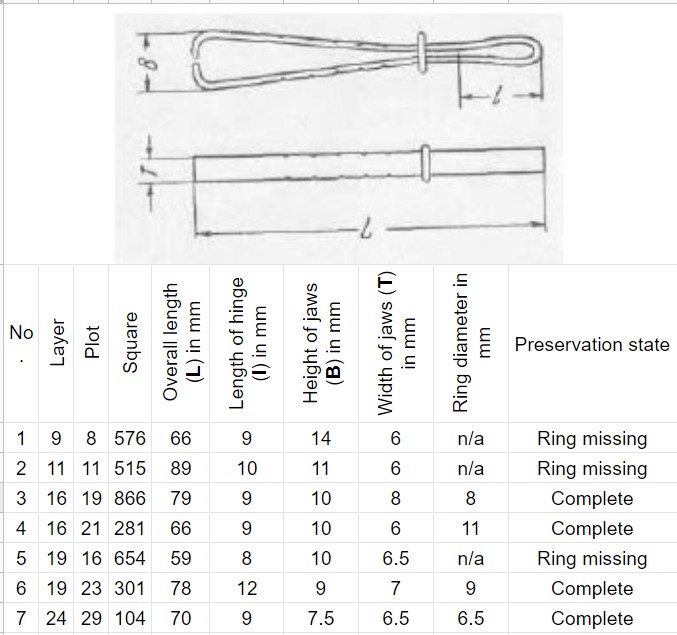

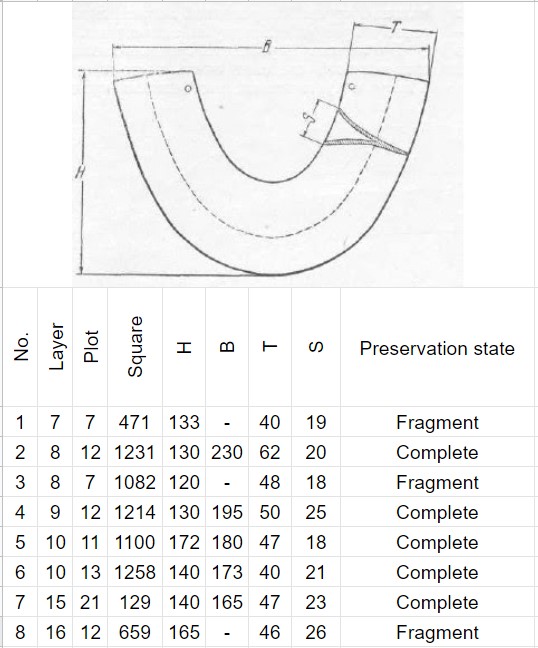

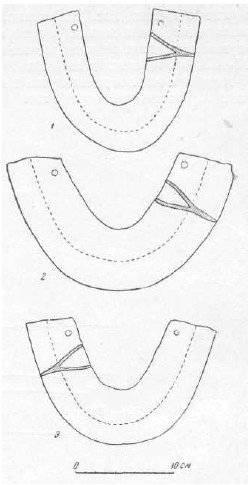

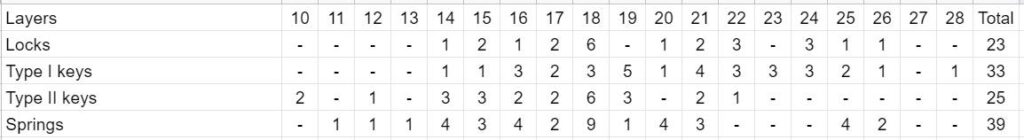

The construction of the second type of tweezers is more interesting. Their form, size (in millimeters) and location by layer is shown in table 3. Tweezers of this second type are used as a sort of manual vise. Having grasped a small item (thin plate, wire, etc.) in the jaws, the artisan would be able to easily work upon it.

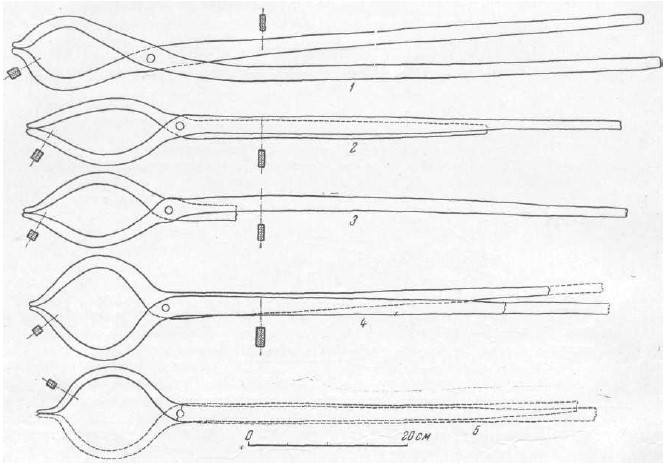

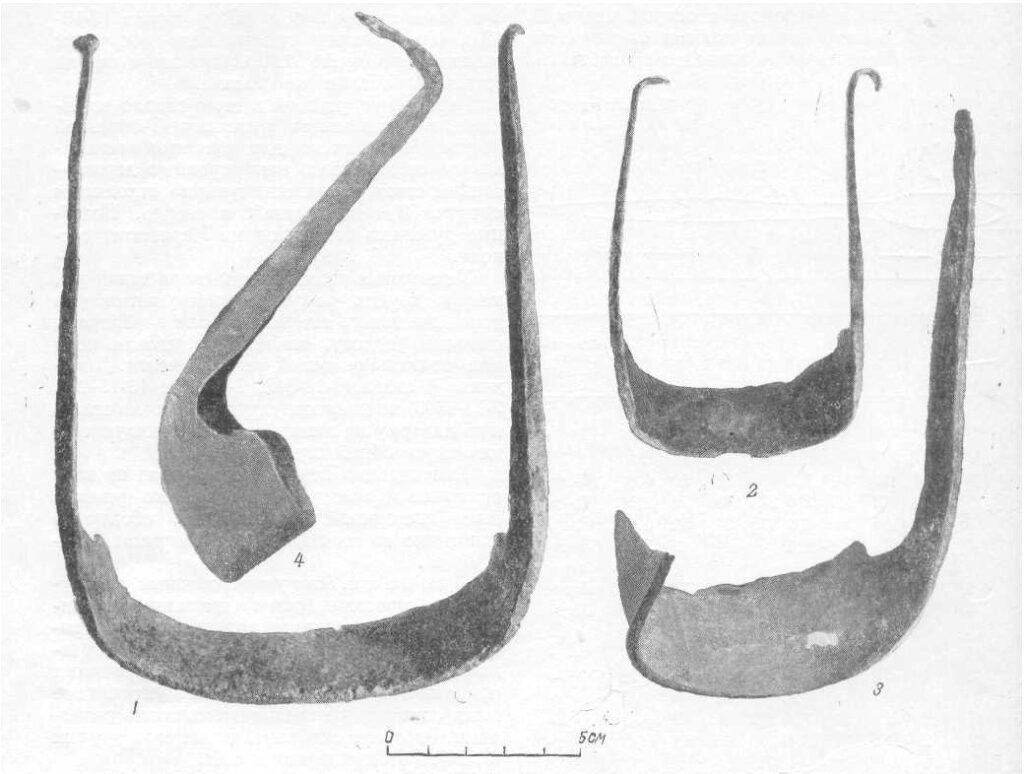

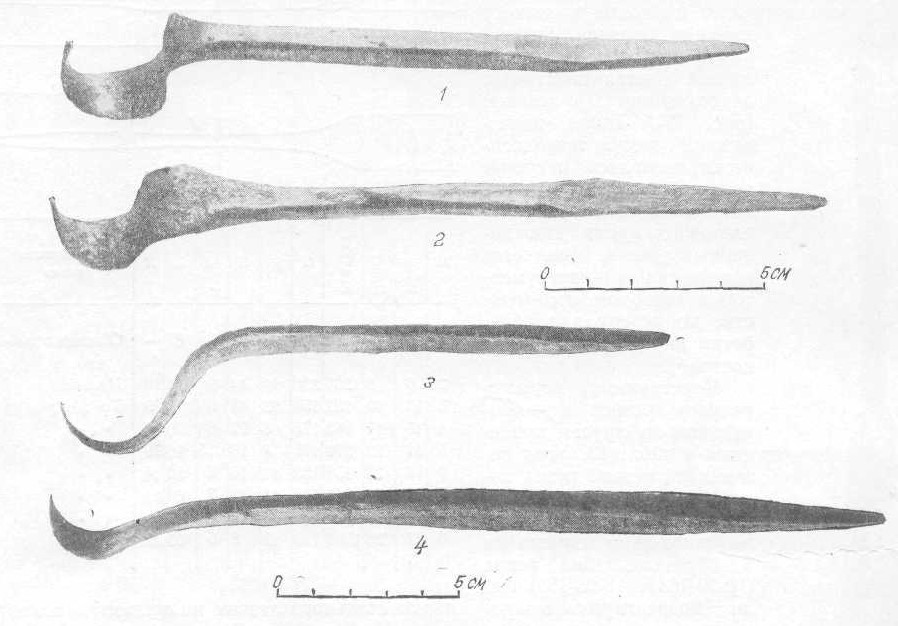

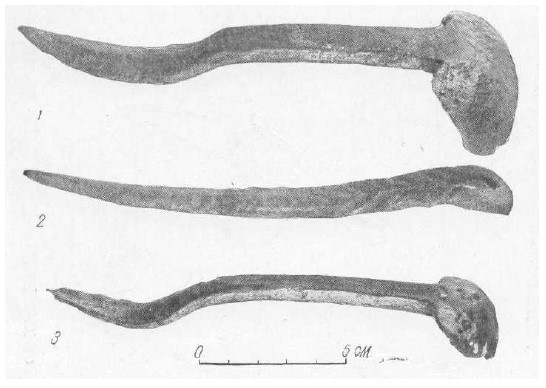

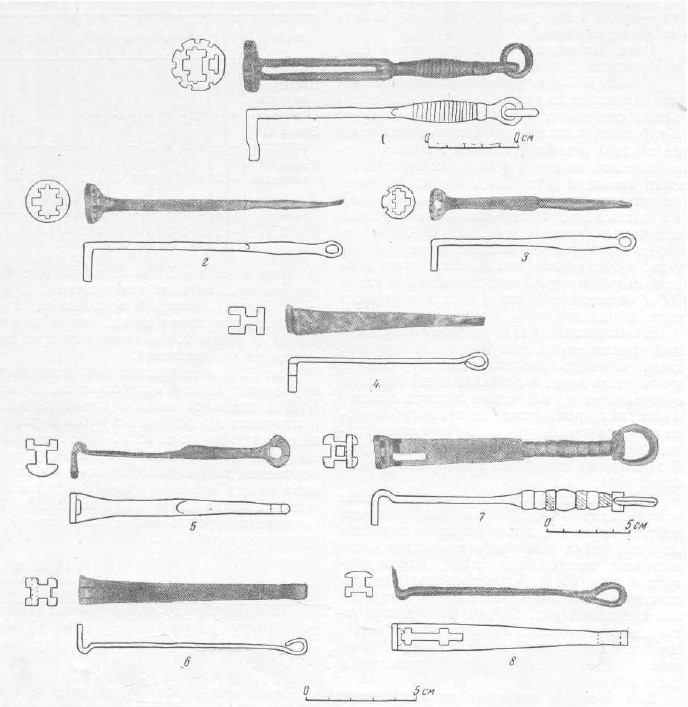

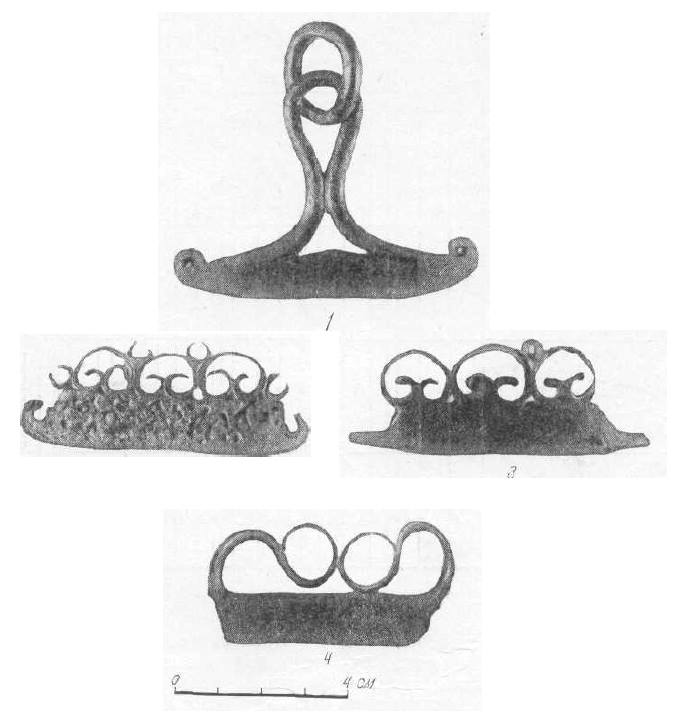

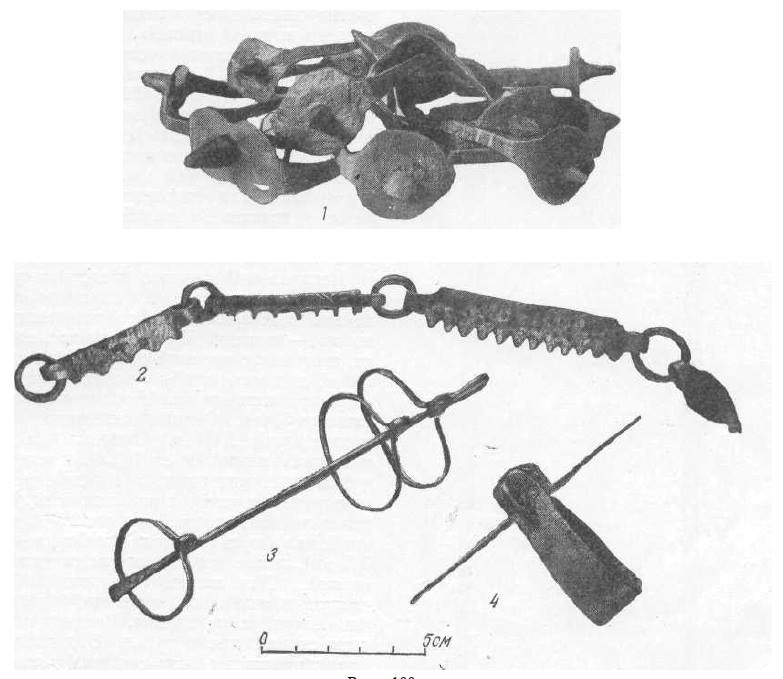

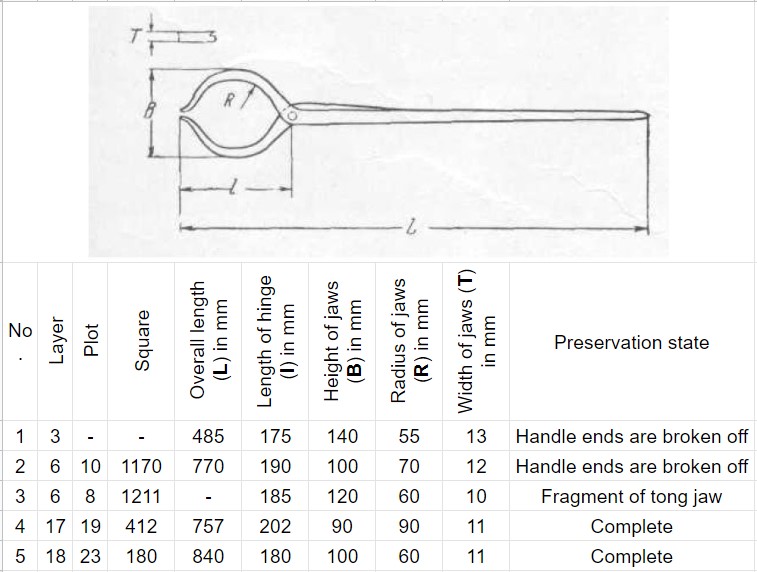

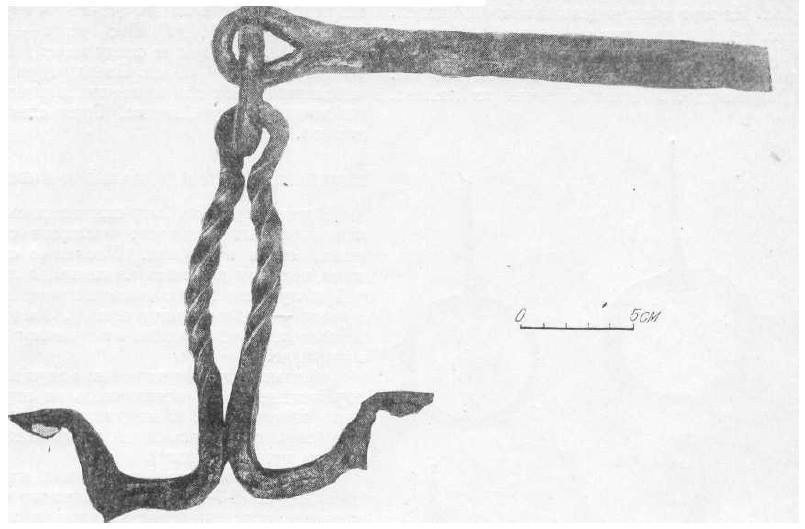

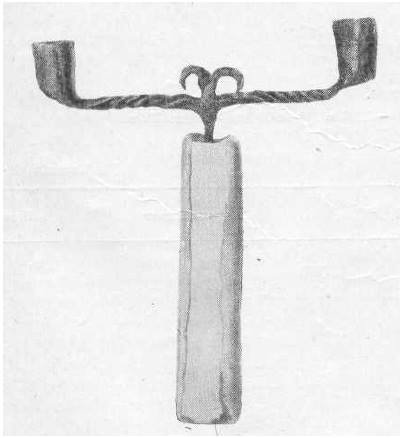

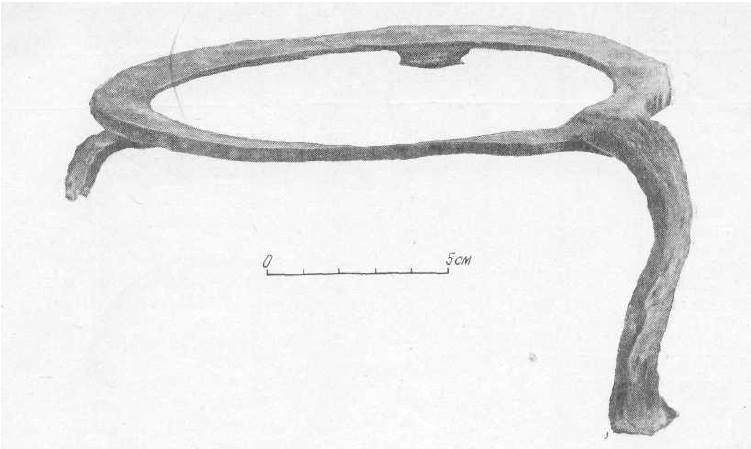

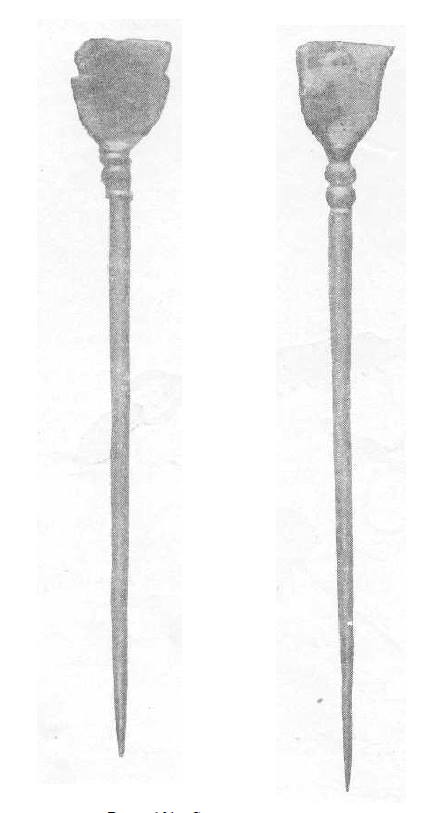

Crucible tongs [Rus. кричные клещи, krichnye kleschi]

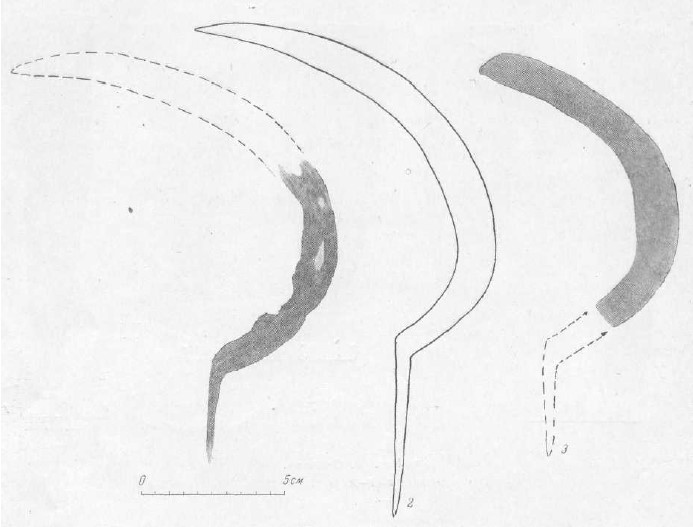

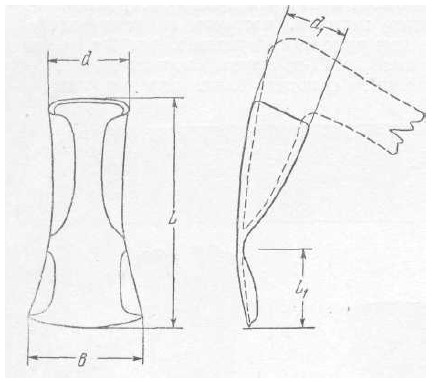

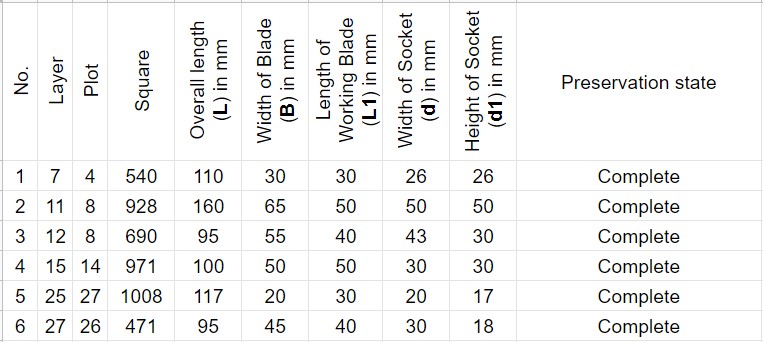

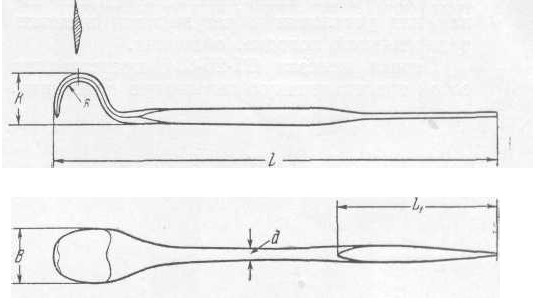

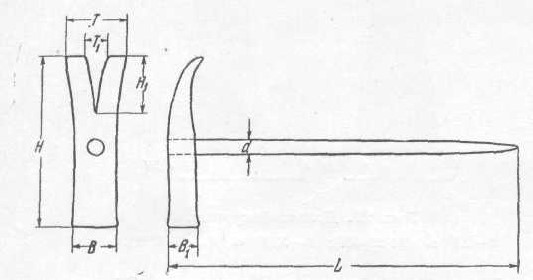

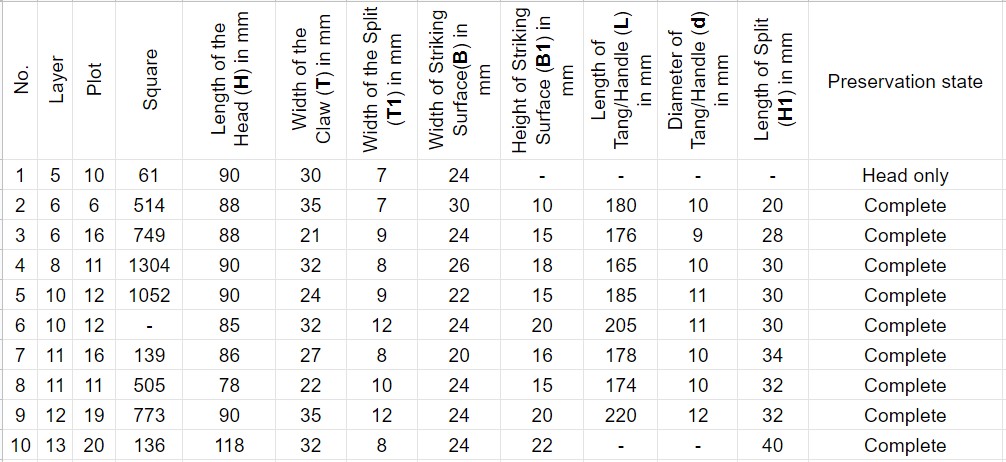

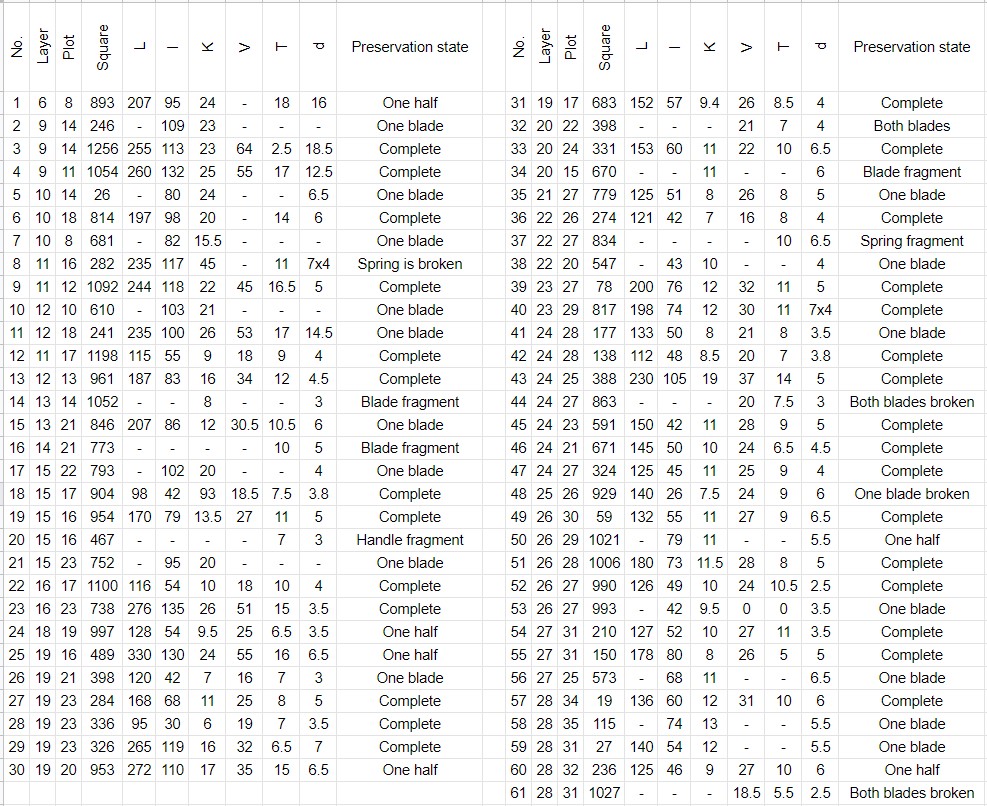

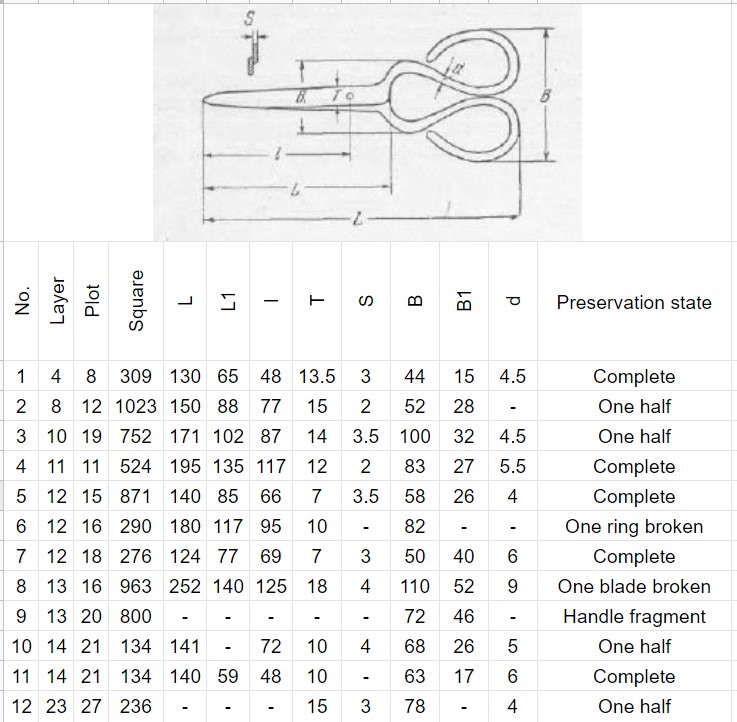

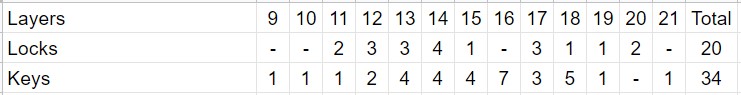

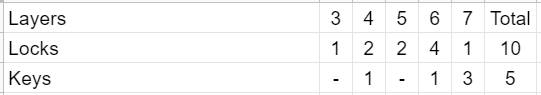

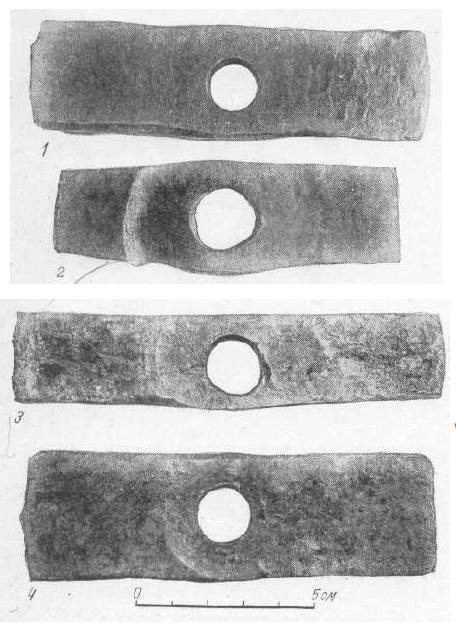

Among the antiquities of medieval Novgorod, this specialized tool used by metallurgists and ukladniki is represented by 5 examples. These tongs were found in layers from the 12th-15th centuries, and they all have large, characteristically rounded jaws for grasping blooms or crucibles, as well as long handles (illustration 8). The form and dimensions of these tongs (in millimeters) and their distribution by layer is shown in table 4. In addition, in layers from the 13th and 14th century, 2 broken handles from this type of tongs (14-16-407, 10-12-1108) were found. These handles were 560 mm and 540 mm in length, respectively.

1-12th cent. (18-23-180); 2-12th cent. (17-18-412); 3-late 14th cent. (6-10-1170); 4-late 15th cent. (on the pavement of the 3rd tier); 5-late 14th cent. (6-8-1211)

Woodworking Tools

For the processing of wood, especially decorative material in the everyday life, technology and construction of medieval Rus’, many technically varied and constructively perfected tools were used. Carpenters and turners, shipwrights[23]jeb: Rus. учанник, uchannik, “one who builds учаны / uchany, ‘river ships’.” and coopers, ladle-makers and wood carvers had an abundance of such tools. This is why woodwoorking tools make up one of the largest groups of archeological finds encountered in medieval urban and rural layers. These tools are also numerous and widely varied in the collection from the Nerevsky dig. Over the dig’s five years, in layers from the 10th-16th centuries, the following tools have been discovered: 72 axes, 7 adzes, 8 saws, 28 chisels, 15 drills, 18 drawknives, one-handed drawknives [Rus. скобелька, skobel’ka, “little drawknife”], 7 slicks [Rus. стамеска, stameska, ‘hand-pushed chisel’], 9 woodturning gouges [Rus. токарный резец, tokarnyj rezets, “lathe tool”], 2 cooper’s crozes [Rus. уторная пилка, utornaja pilka, “croze file”], 2 curled chisels [Rus. фигурное долото, figurnoe doloto], 3 rounded gouges for artistic carving, and 15 nail pullers [Rus. гвоздодёр, gvozdodjor]. This nomenclature includes all forms of woodworking tools found from medieval Rus’.

Finds from the Nerevsky dig were distributed more or less equally throughout all layers. Each tool was typically located among everyday, household, or other items, but a few toolkits were also found. The most interesting selection of tools was uncovered in a woodworker’s workshop from the turn of the 12th-13th centuries. This workshop was located in the courtyard of manor “B” near the intersection of Velikaya and Kholop’yaya Streets and was found in layers 15 and 14. It was destroyed sometime in the 1220s. The remains of this workshop included a saw (15-15-963), an adze with a wooden handle (15-14-971), a drawknife (15-14-952), a cutting tool (15-17-942), a chisel (15-17-952), and not far from the workshop, an axe (14-16-900).

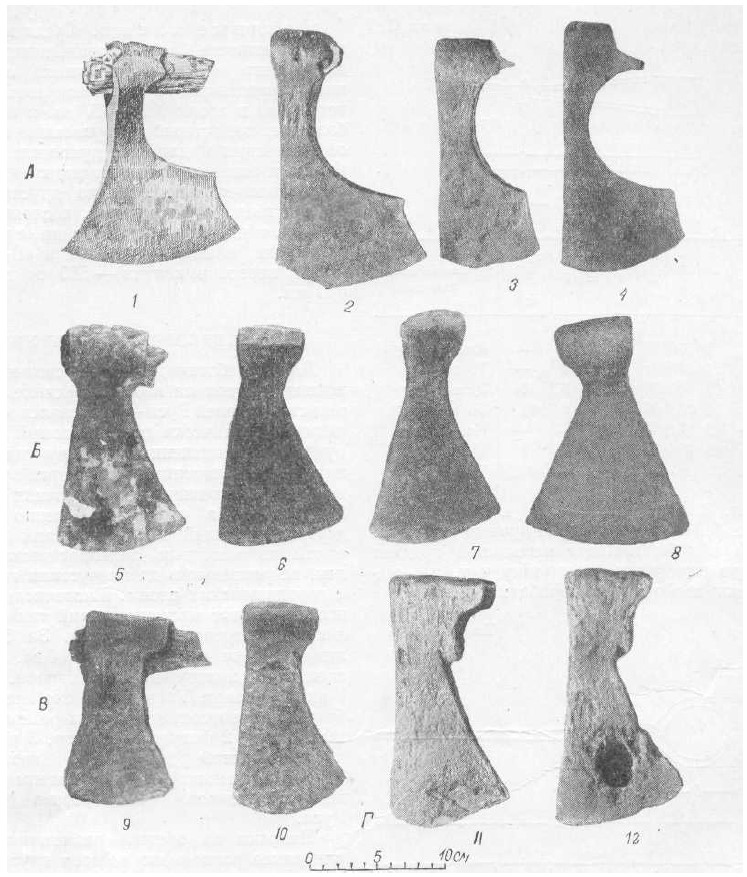

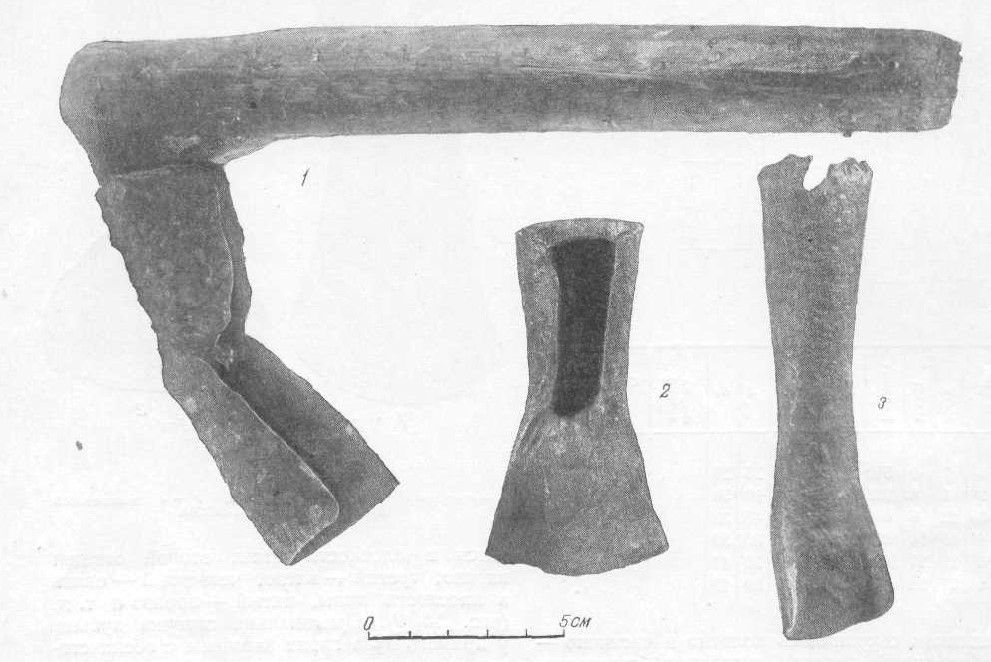

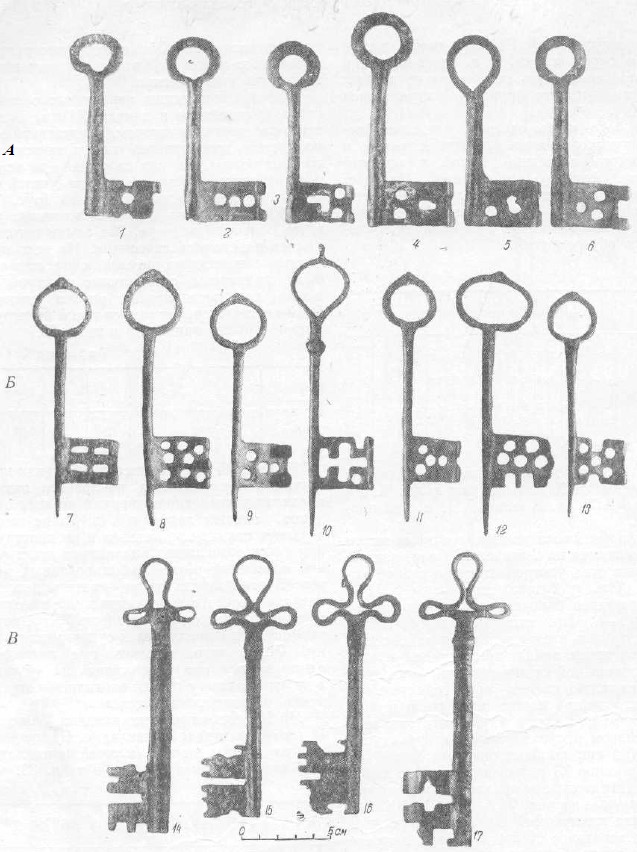

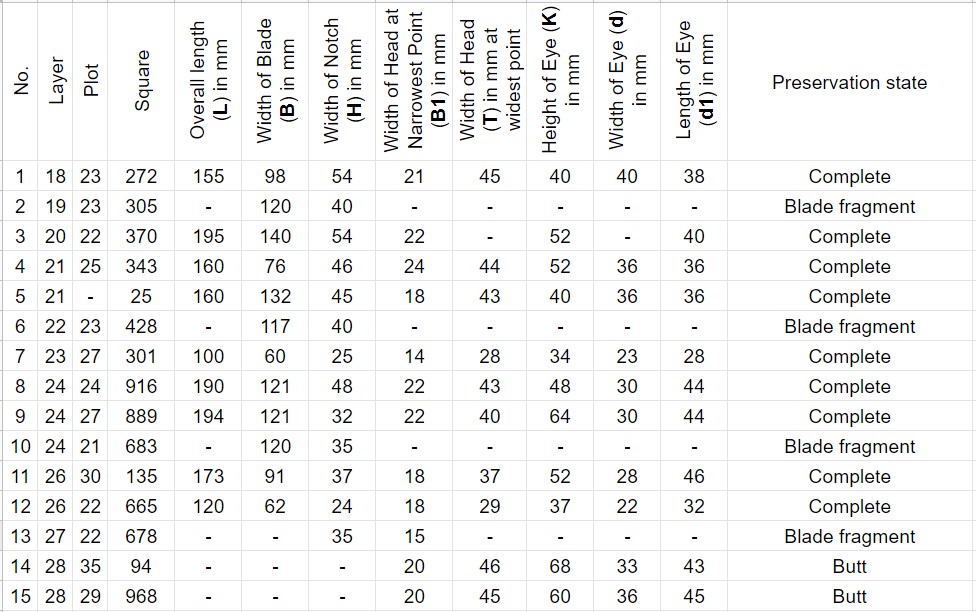

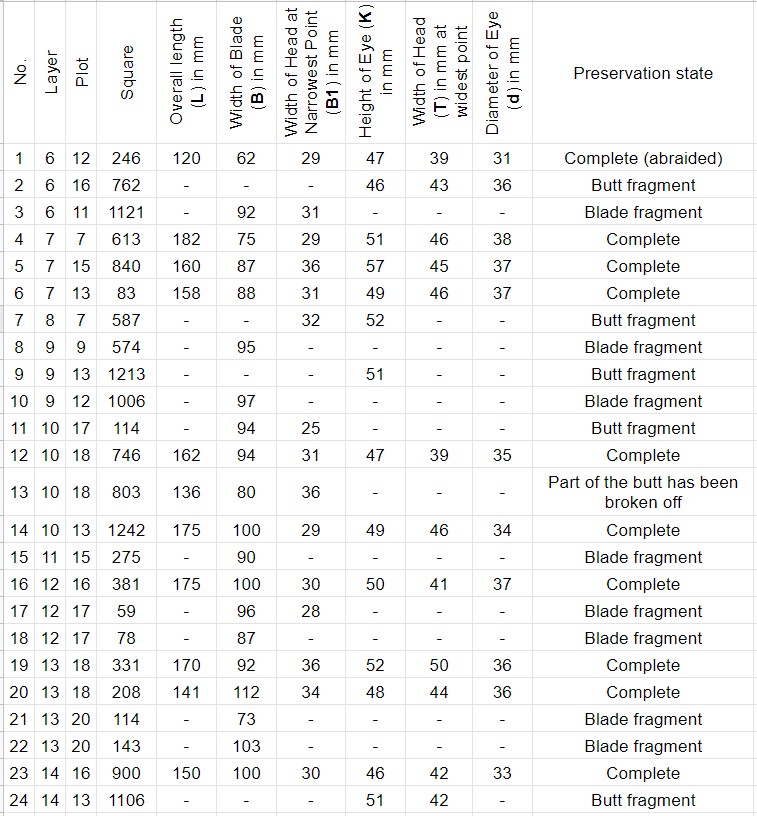

Row 1 (“A”) – First type: 1-11th cent. (21-00-25); 2-11th cent. (24-24-916); 3-11th cent. (21-25-343); 4-10th cent. (26-30-137)

Row 2 (“Б”) – Second type: 5-13th cent. (13-18-331); 6-late 13th cent. (10-18-746); 7-14th cent. (7-13-83); 8-13th cent. (13-18-208)

Row 3 (“B”) – Third type: 9-15th cent. (5-15-716); 10-15th cent. (5-15-715)

Row 3 (“Г”) – weighted axes of the third type: 11-15th cent. (5-00-00); 12-15th cent. (5-8-1034)

Several sets of 2-3 tools were found in various layers. For example, a saw and a slick were found together in the courtyard of manor “B” in the 23rd layer. A drawknife and a decorative chisel were found near building 17L. Two axes, a cutting tool, and a nail puller were discovered in the courtyard of manor “A” (in the 13th-12th layers), where a jeweler lived. In the same layers, in the courtyard of manor “D”, a saw and an adze were found together. Similar sets were also found in the 25th, 21st, 11th, and 10th layers.

We will describe each item in detail, following the order listed above.

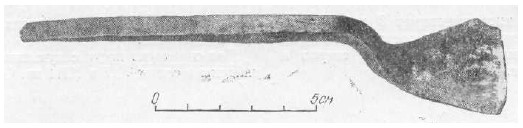

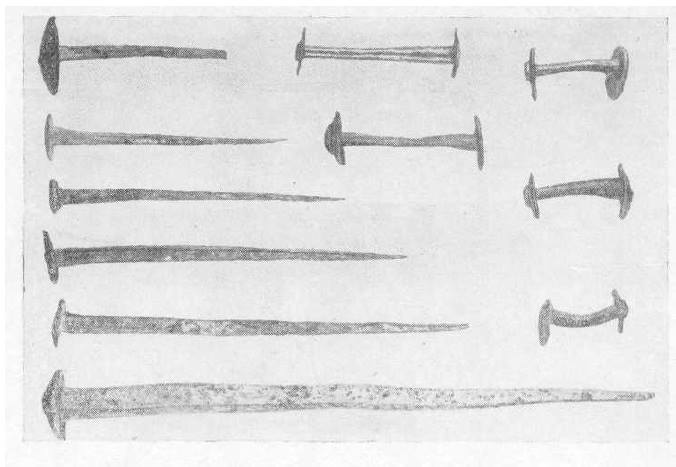

Axes [Rus. топор, topor]

Axes made of stone, then copper, bronze, iron, and finally steel were basic and the most versatile tools for working wood over the course of many centuries. Steel axes became widely used in medieval Rus’. They were widely used not only by professional craftsmen or builders, but by almost every urban and rural inhabitant. In the vast majority of dwellings in the Nerevsky excavation, independent of their owners’ professions, archeologists discovered one or two axes (or their fragments) amongst the plethora of household items.

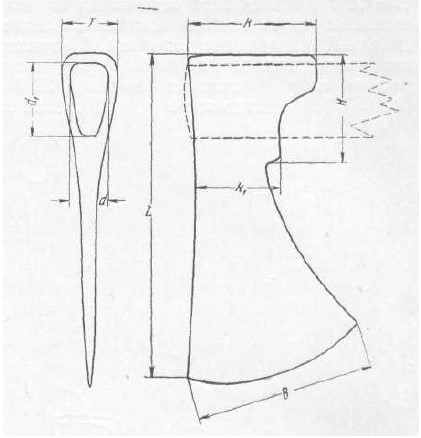

The construction, form and technology for creating the medieval Russian, wide-bladed eyed axe was developed in the second half of the 1st millennium CE.[24]A detailed trace of the chronological evolution of the development of iron axes in Eastern Europe, in particular in the second half of the 1st millennium CE, is not possible at this time due to a lack of archeological data. In Novgorod, in the earliest layers dating to the 10th century, we encounter wide-bladed eyed axes of an already developed form. This form was modified over the subsequent centuries in some elements, but the construction itself and its basic parts remained has stable up to modern times.

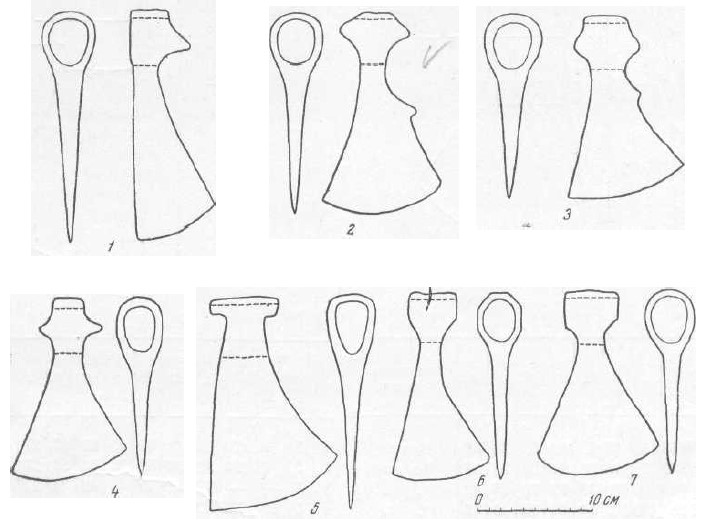

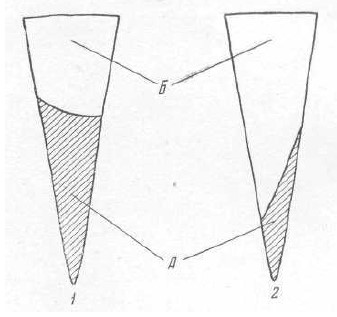

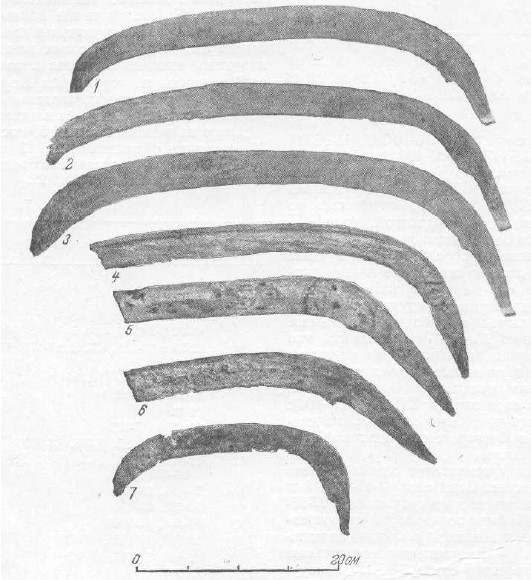

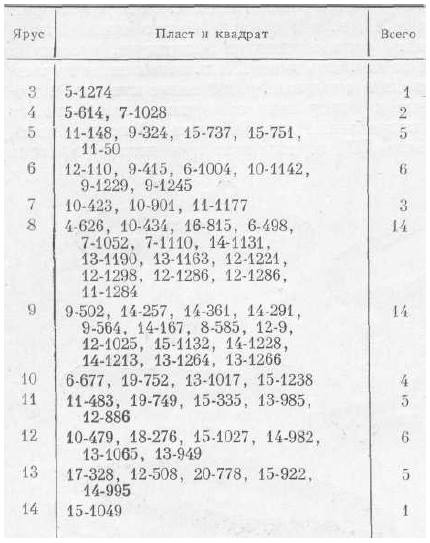

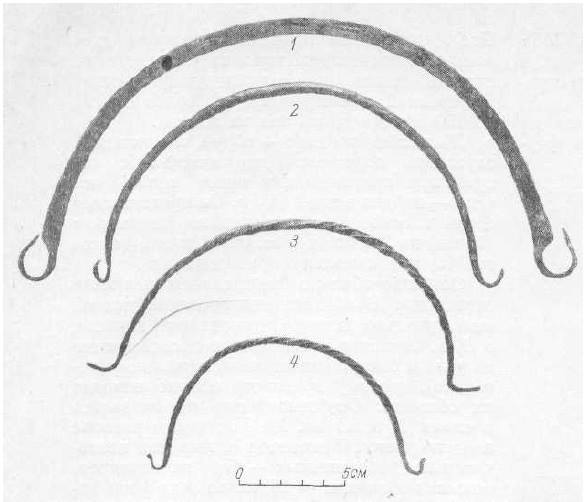

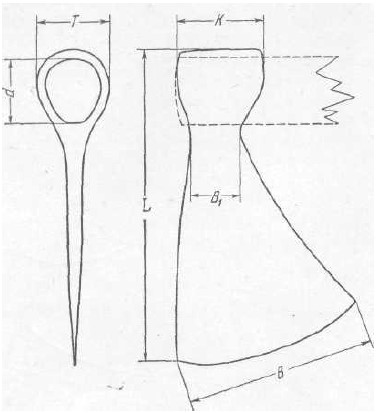

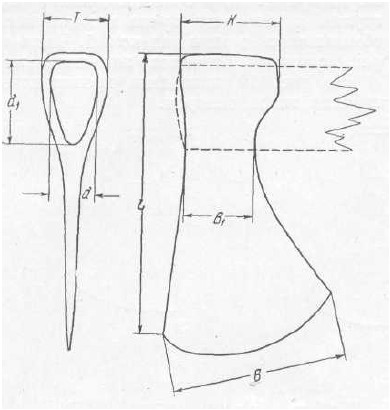

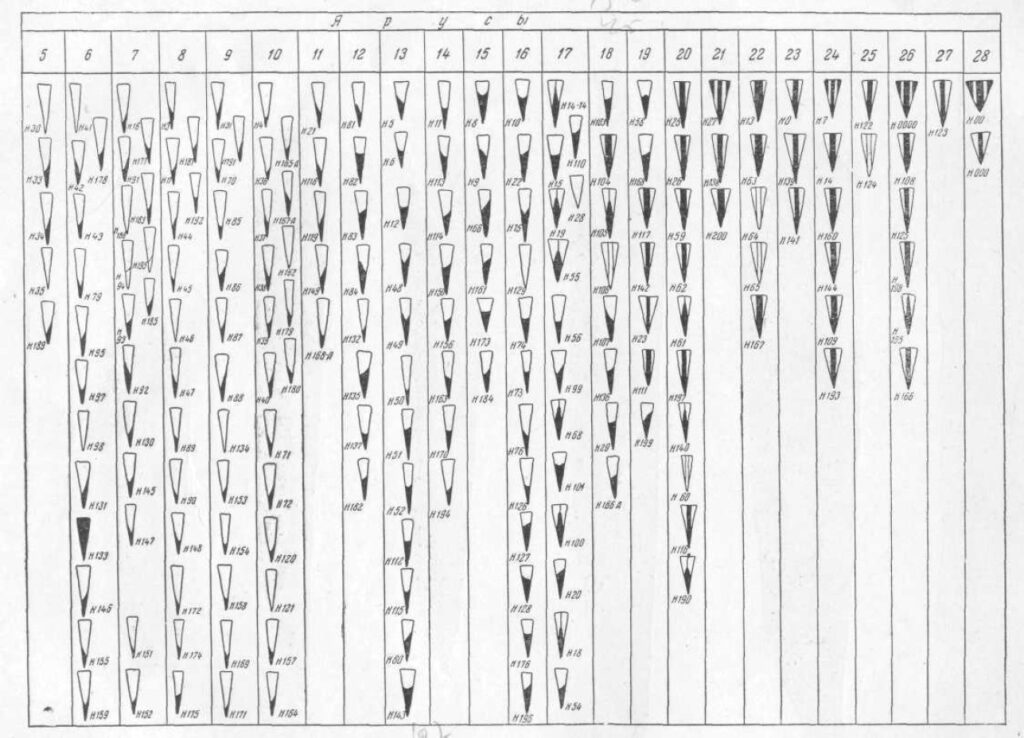

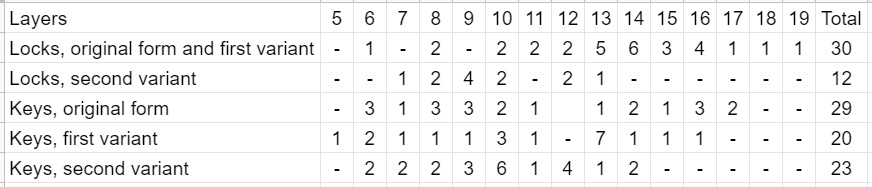

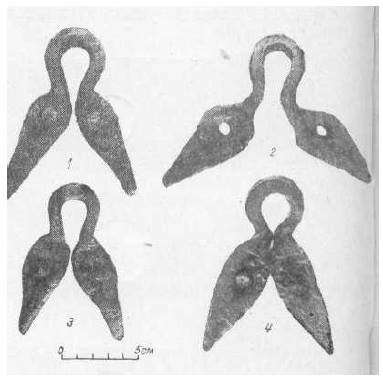

From the entirety of Novgorod axes, we can distinguish three basic chronologically successive types and several transitional and individual forms (illustrations 9 and 12).

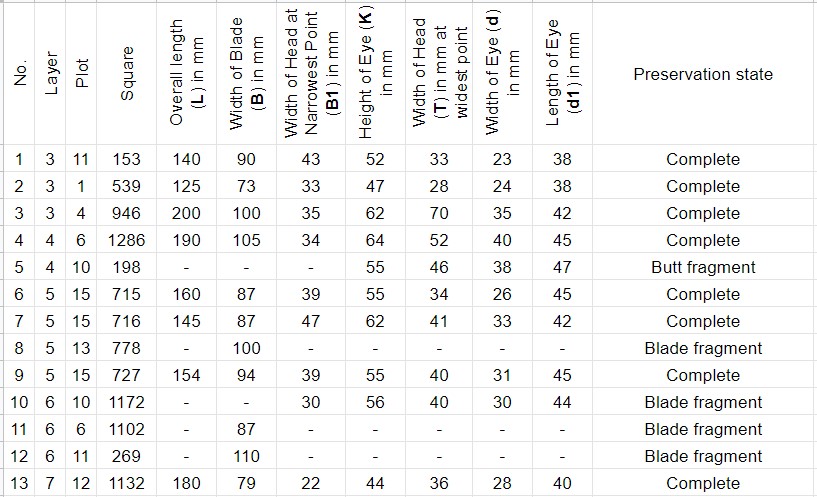

The first and oldest type of axe (15 were found, plus one in a later layer, where it ended up as a result of digging) has a massive, wide, lowered blade, with a notch and an eyelet with one inner flange (illustration 9, A). The dimensions of these axes and their distribution by layer is shown in table 5. The cutting angle of these axes’ blades is around 20°. The average weight for large axes was around 850 g. For fine cooper’s, woodturner’s and carpenter’s work, there were lighter axes of the same type, but with smaller blades, with lengths running from 60 to 120 mm. Axes of the first type were used in the 10th and 11th centuries, and up to the middle of the 12th century (28th-18th layers).

In the second half of the 12th century, two transitional forms of axe appeared. In one of these, which continued the configuration from the first type, the notch in the blade was significantly smaller, with a small beard at the bottom of the notch (illustration 10, 2 (side)). Similar axes (5 examples) were found in the 17th-14th layers. Axes of the second transitional type (6 example) found in the 17th-14th layers, have symmetrical blades and a lightweight butt (illustration 10, 4, 7). Axes of this type later developed into the second type of axe.

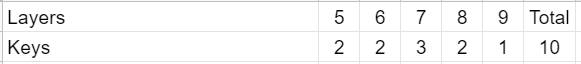

Axes of the second type (24 examples have been found) have symmetrical blades, and are somewhat lighter and thinner than those of the first type, with a rounded butt (illustration 9, Б). The form and dimensions of these axes of the second type and their distribution by layer can be seen on Table 6. These axes were relatively light, weighing around 670-700 g on average. This type of axe appeared in the 13th century and existed to the end of the 14th century (14th-16th layers).

Around the turn of the 14th-15th centuries, axes of the second type became noticeably heavier, the blades became more asymmetrical, and the butt became more massive, with a flat (or nearly flat) upper surface, while the blade itself became smaller (illustration 9, В). We shall divide these out into a third type (with 13 examples found). The dimensions of these axes and their distribution by layer is shown in Table 7. The average weight of these axes was 600 g. Axes of this type existed for the entire 15th century and into the 16th century (7th-3rd layers).

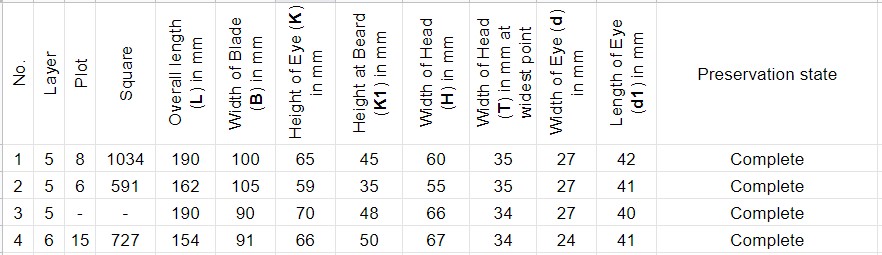

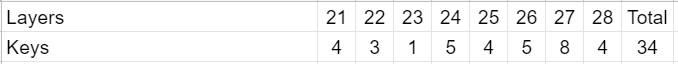

At the same time, in the first half of the 15th century, a heavier form with an elongated, flat butt (illustration 9, Г) emerged. Four examples have been found of this type. The form and dimensions of these axes are shown in Table 8.

Aside from the axes of the listed types, 4 axes were found with individual shapes. In a 10th century layer, an axe (26-24-611) was found of a type which is sometimes encountered in military burial mounds from the 9th-10th centuries.[25]Brandenburg, N.E. “Kurgany Juzhnogo Priladozh’ja.” Materialy po arkheologii Rossii. 1895 (18), St. Petersburg. This axe had an elongated shape (210 mm in length), with a narrow blade (78 mm wide) and with “earflaps” on the butt. This axe weighed 836 g (illustration 10, 1). In a layer from they 14th century, 2 axes were found of a decidedly original construction. One of these (8-11-1272) has a blade similar to those on type two axes, and had a narrow neck and a faceted butt (illustration 10, 6). On the other one (8-13-220), the wide curved blade goes directly, without a neck, into a butt with a flattened upper surface (illustration 10, 5).

1-10th cent. (26-24-611); 2-12th cent. (17-24-101); 3-13th cent. (14-12-681); 4-13th cent. (14-21-772); 5-14th cent. (8-13-220); 6-14th cent. (8-11-1272); 7-13th cent. (14-10-659)

Aside from the large number of working axes, there were also a number of small children’s toy axes found. All of these, depending when they were created, were completely identical in form to the larger working axes of the time. For example, a 10th century hatchet (26-29-1057) had the form of axes of the first type, while a hatchet from the early 14th century (10-15-1204) with a wooden handle was made following the second type of axe. These hatchets were usually created simplistically, from strip iron, without any welds, but one hatchet (22-27-106) was made by all the rules of blacksmithing technology, with a welded butt and even even a welded blade.

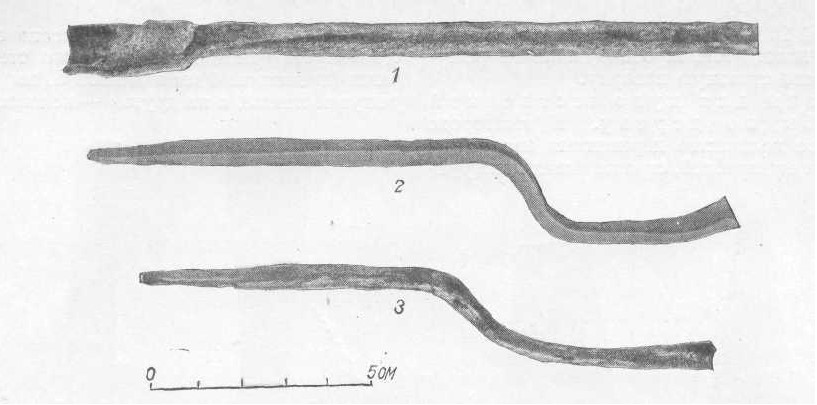

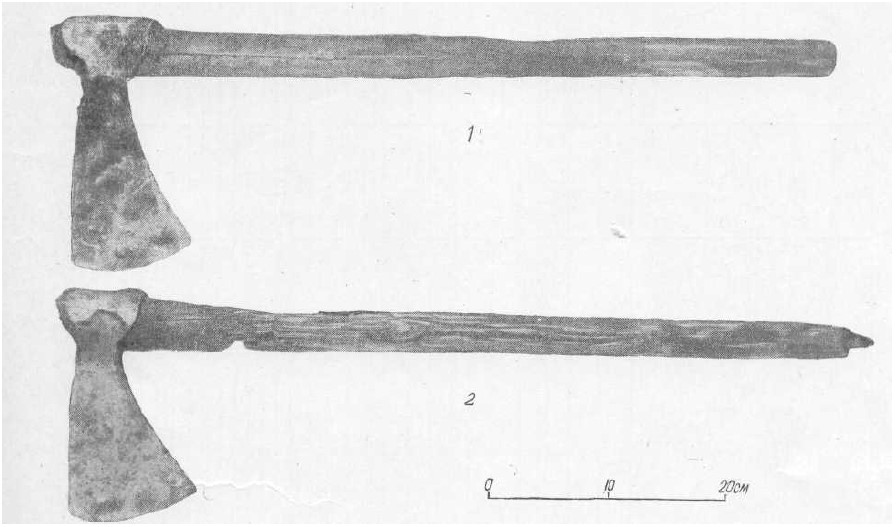

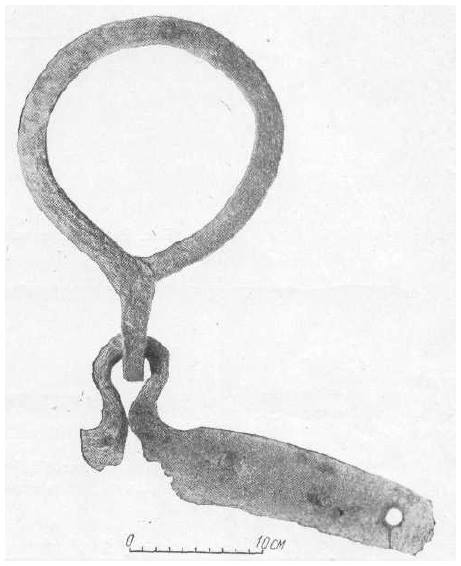

To conclude our discussion of the construction of axes, let’s take a look at their handles [Rus. топорище, toporische]. Thanks to the exceptionally good preservation of wood in the Novgorod cultural layer, 8 axes were found along with their wooden handles. Depending on the shape of the axe’s eye, they had either round or oval cross-sections. These handles were all straight and relatively elongated (illustration 11). On average, the handles were around 650 mm in length. The method of attaching the axes to their handles was interesting. For a more snug fit of the axe handle to the axe, the handle was wrapped in a single layer of leather where it passed through the butt. Often, an iron wedge was also driven into the end of the handle.

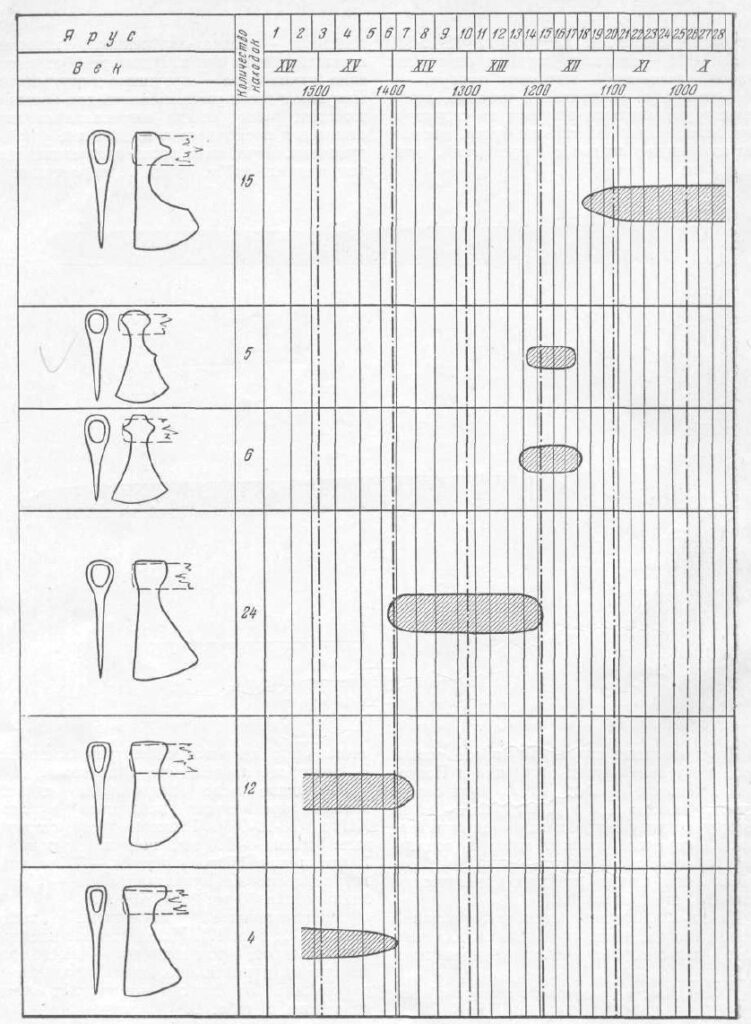

Illustration 12 shows a chronological table of types of axes.

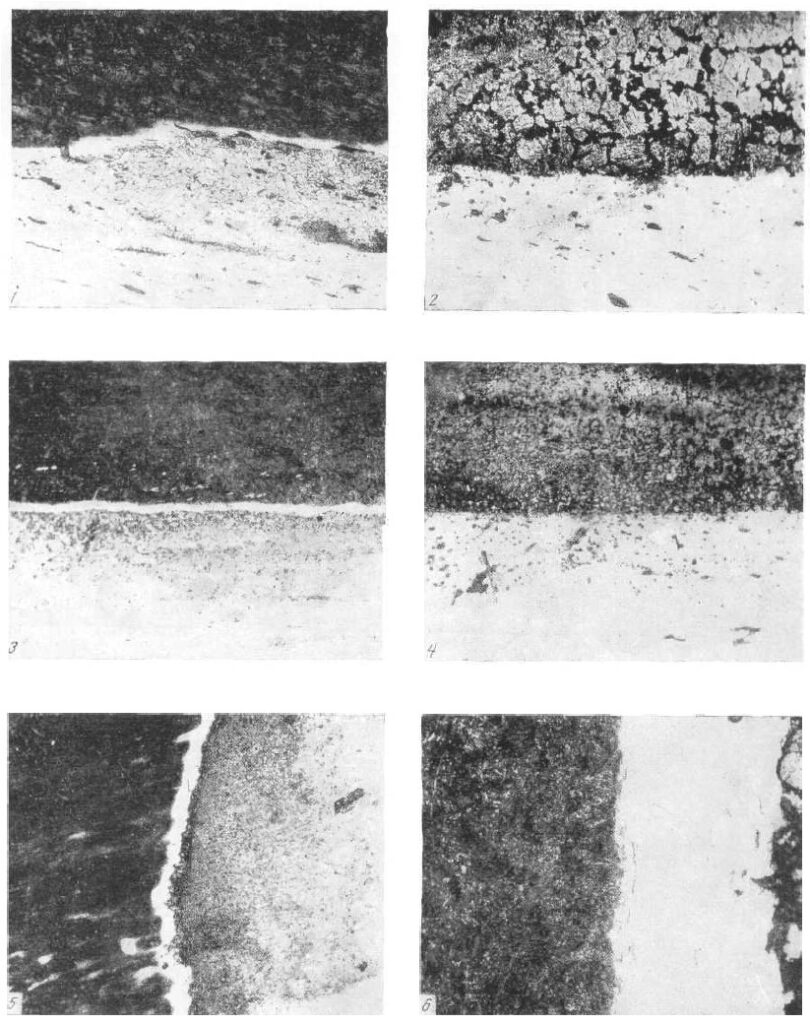

In order to study the technology used to create these axes, we subjected 15 examples to structural examination. These included 5 axes from the 14th-15th centuries (5-13-778, 8-13-220, 9-9-574, 9-12-1006, 9-14-000), 7 axes from the 13th century (11-15-275, 13-20-143, 14-17-421, 12-16-381, 10-17-114, 14-21-772, 14-16-900), 2 axes from the 11th century (24-27-889, 24-21-683), and an axe from the 10th century (26-24-611). Microsections were taken from 9 of these axes’ blades; of these, on 3 examples we preliminarily made microsections of the entire cross-section, and the remaining 6 were subjected only to macro-etching. Both the microstructures and macrostructures showed that on all 15 axes, there was a rod of steel welded into the cutting edge (illustration 13). This appears to have been a common medieval Russian technology, combining iron and steel to produce a single item, thanks to which the axe had a level of viscosity in the body, along with hardness and durability in the blade.

The welding seams which joined the iron and steel were, for the most part, thin and clean, providing evidence of the great mastery of the Novgorod blacksmiths who made these axes. Illustration 14, 3, 4 shows the welding seams from the blades of 13th and 14th century axes.

Illustration 12: Chronological table of types of axes

[jeb: translations: Ярус-Layer; Век-Century; Количество находок-Number of Finds.]

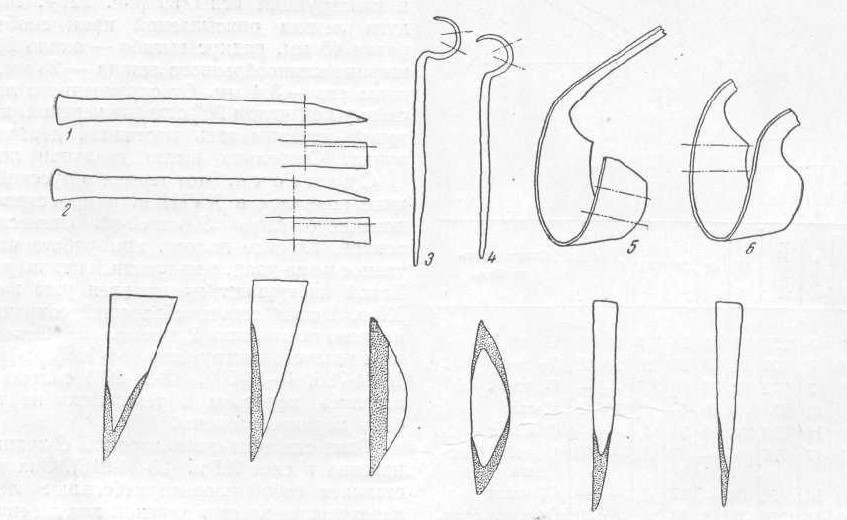

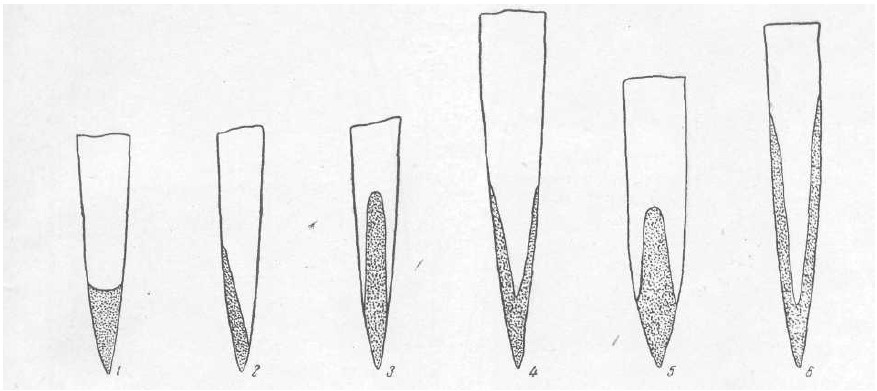

Illustration 13: Technological diagram of axe blades.

Dark field – steel; white – iron

1-13th cent. (11-15-275); 2-14th cent. (9-9-874); 3-15th cent. (5-13-778); 4-13th cent. (14-21-772); 5-11th cent. (24-21-683); 6-13th cent. (14-17-421)

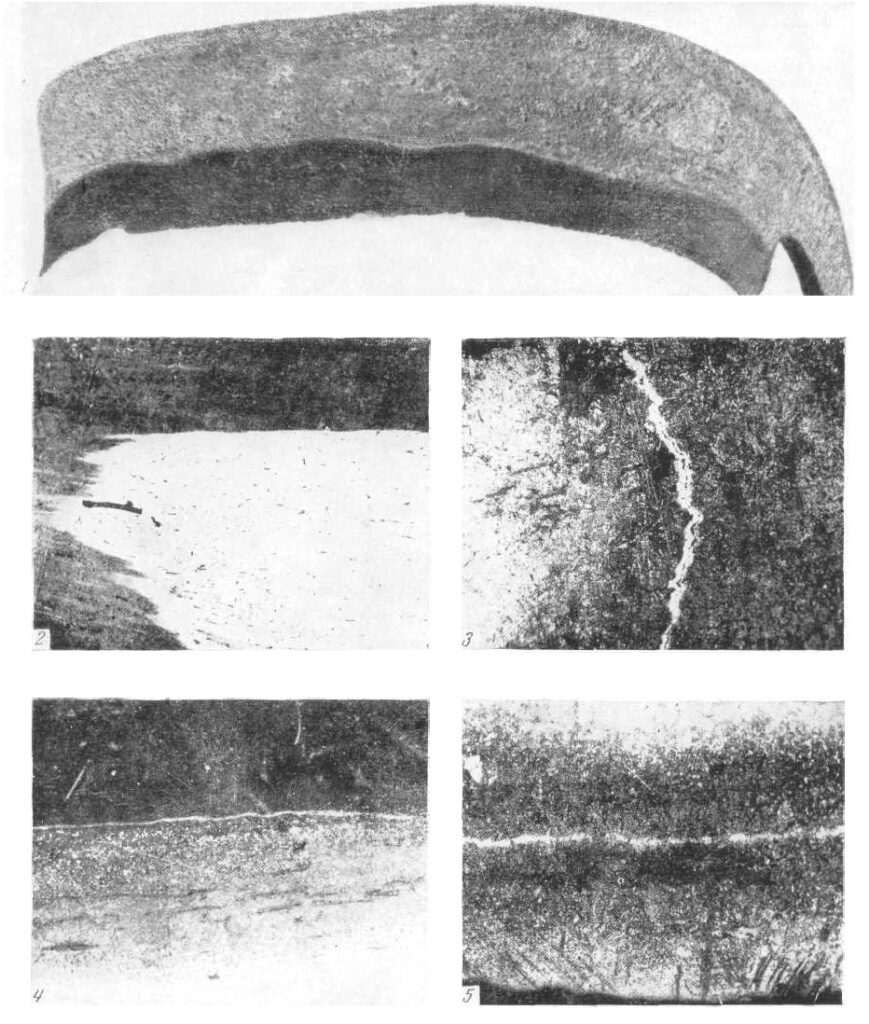

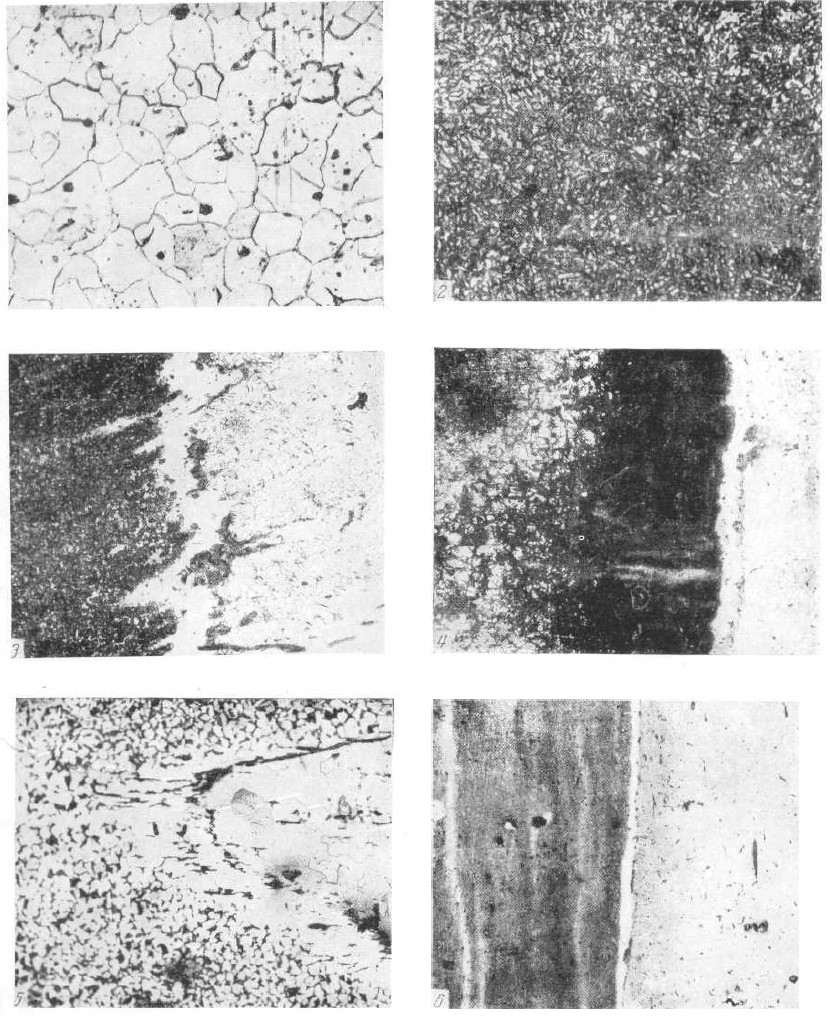

Illustration 14: Microstructures. Magnification 140x

1-bloom, late 13th cent. (10-8-519), ferrite; 2-file, 15th cent. (7-9-928), troostite-martensite; 3-14th cent. axe (9-9-574), weld seam; 4-13th cent. axe (11-15-275), weld seam; 5-chisel, 12th cent. (17-18-941), weld seam; 6-chisel, 13th cent. (12-13-1025), weld seam.

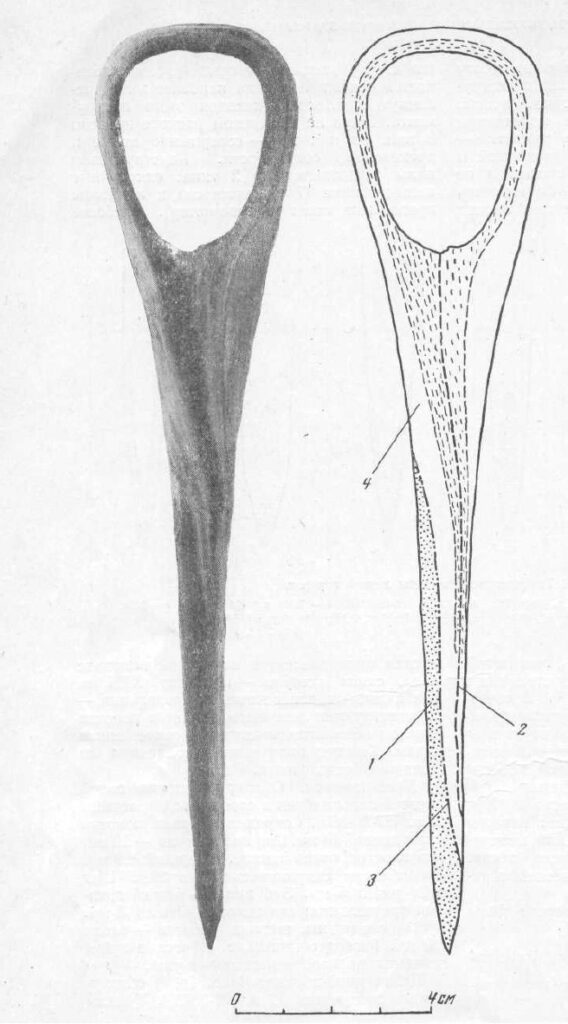

Illustration 15: Cross-section, 11th cent. axe (24-27-889)

1-hardened steel welded onto blade; 2,3-weld seams; 4-body of the axe, welded from two strips (iron and low-carbon steel)

All of the steel blades from these axes were heat treated. On the axes for which we performed microstructural analysis, we discovered the following structures. Axe 11-15-275 had a martensite structure. 5 axes (9-9-574, 5-13-778, 12-16-381, 14-21-772, 14-17-421) had a troostite-martensite type structure, and 3 axes (10-17-114, 24-21-683, 24-27-889) had a sorbite structure. The hardness on the Rockwell scale C of these steel blades measured 51 (9-9-574), 53 (12-16-381) and 48 (13-20-143) units. The hardness of the iron bodies of these axes measured around 40-41 units on the Rockwell scale B.

We used 2 technological methods on the cross-sections of three axes to study the body of those axes. On axe 24-27-889 (illustration 15), the butt was created by folding the blank of iron in the middle then forging the blade. On axes 12-16-381 and 10-17-114, one end of the iron blank was looped around and then forged back into the body of the axe. We are only reconstructing in brief the technology of creating axes based on the results of our structural analysis, as it is completely similar to the technology we have already previously discussed.[26]Kolchin, Chernaja metallurgija…, pp. 104-108. As such, study of the structures of these axes showed that their method of manufacture in Novgorod from the 10th-15th centuries was completely the same. In both the 10th and 15th centuries, an iron axe body was welded to a steel blade subjected to heat treatment, that is, quenching and tempering, which fully met the technical needs of these items.

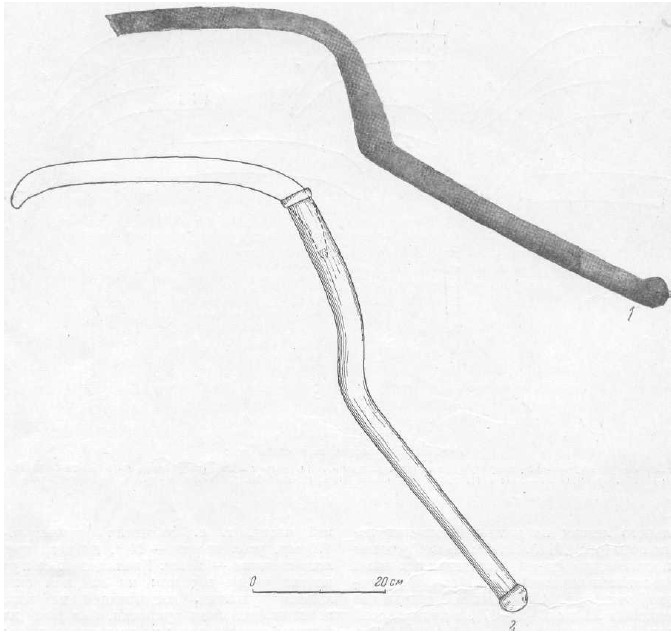

Adzes [Rus. тесло, teslo]

1-eyelet adze, 13th cent. (13-12-506); 2-with a conical socket, 13th cent. (11-8-928)

As a specialized form of axe, adzes were used for rough preparation of recesses in wooden objects: dugout boats, troughs, ladles, spoons, etc. In medieval Rus’, there were two types of adze: eyelet, and socket. Eyelet adzes were used for large, heavy work, and were always large and affixed to a long, straight handle. Socket adzes were intended for fine work, and were lighter and often created with a shaped blade. Both types of adzes have been found in Novgorod.

Eyelet adzes are represented by a single example found in a 13th century layer (13-12-506). The dimensions of this adze are: width – 160 mm, blade width – 70 mm, width of the neck at the eye – 30 mm, diameter of the eye – 35 mm, length of the butt – 40 mm (illustration 16, 1).

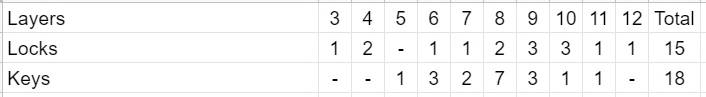

Socketed adzes are more commonly found (illustration 16, 2; illustration 17). Six examples were found in the Nerevsky dig, of which 2 were found along with their wooden handles. Their form, size and distribution by layer is shown in Table 9.

Socketed adzes, intended for use with one hand and with a small tool span (for making pans, ladles, bowls, spoons, etc.) had a light, bent handle (illustration 17, 1). The handle was no more than 275 mm in length. The angle between the handle and the plane of impact was beveled and did not exceed 60°. Tools of this form were very convenient and most rational for light hand work. It is worth noting that a similar form of adze also appeared in the East around the late 2nd millenium BCE.[27]Flinders Petrie, W.M. Tools and weapons. London, 1917, p. 18. Identical socketed adzes have also survived to modern times.[28]Filippov, N. Kustarnaja promyshlennost’ Rossii. St. Petersburg, 1913, p. 168. The large socketed adze (11-8-928) with a conical socket was seated on a long (80 cm), straight handle. It was used to carve mortices in wood boards.

1-with a wooden handle, late 12th cent. (15-14-971); 2-10th cent. (27-26-471); 3-11th cent. (25-27-1008)

The technology for creating adzes in the 10th and 20th centuries are identical: a steel blade is welded to an iron or low-carbon steel flat body. Adze blades were heat treated.

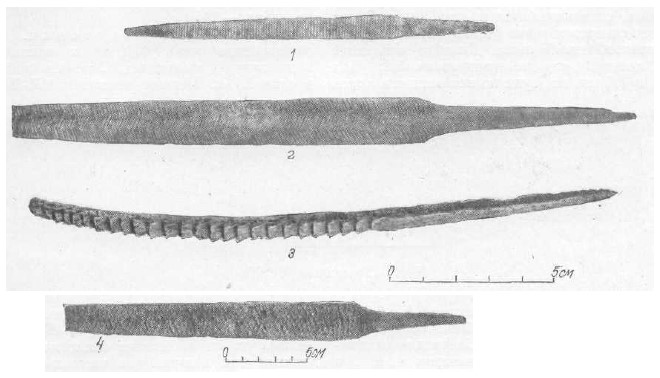

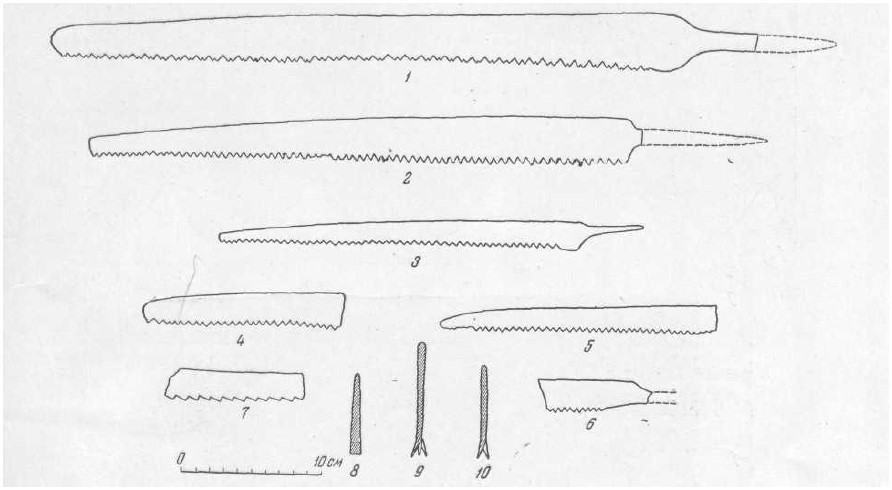

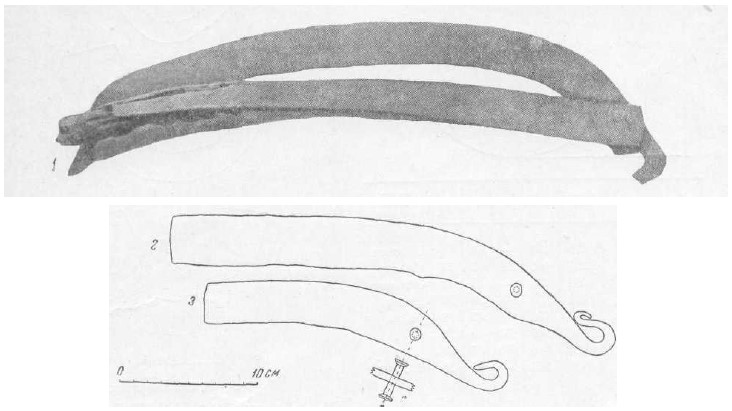

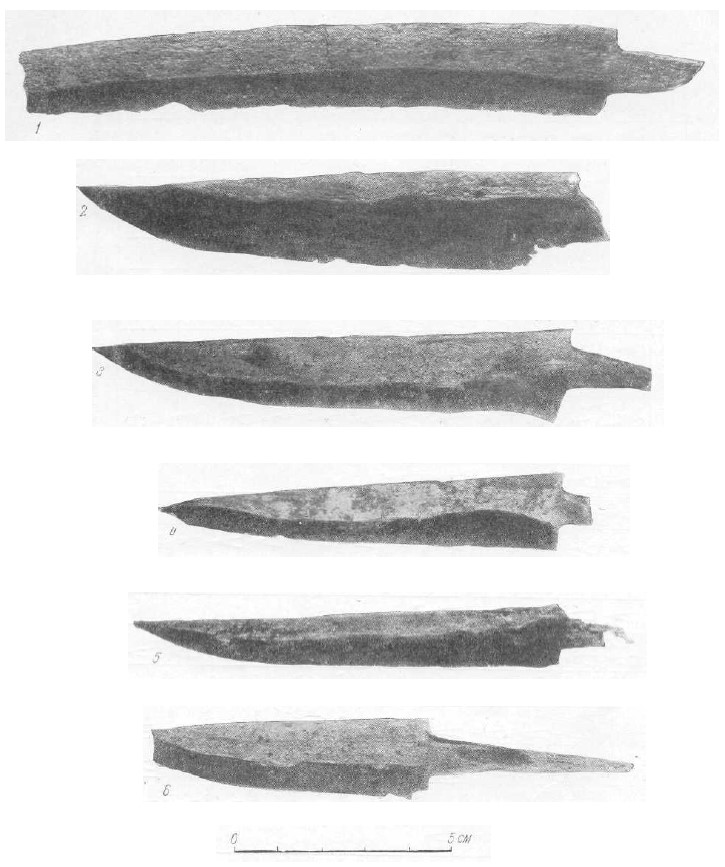

Saws [Rus. пила, pila]

(Wood) saws discovered in Novgorod make up among Russian antiquities the main and to date the largest collection of finds of this tool. In total from the Nerevsky excavation, 8 saws have been found, of this three were completely whole and excellently preserved. In terms of construction, saws are divided into two types: single-handed hacksaws (7 examples) and bow saws (1 example). The earliest saw dates to the second half of the 10th century, while the latest dates to the late 13th century. All saws, both single-handed hacksaws and bow saws, are completely analogous to modern saws in their construction of the cutting teeth and blade. We shall describe each of the saws in our collection separately.

1-12th cent. (15-15-963); 2-11th cent. (21-25-21); 3-13th cent. (13-9-680); 4-11th cent. (22-21-1096); 5-12th cent. (17-20-387); 6-11th cent. (23-24-905); 7-13th cent (10-15-220); 8-cross-section of blade (10-15-220 #7); 9-cross-section of blade (21-25-21 #2); 10-cross section of blade (13-9-680 #3)

Hacksaw blades [Rus. пила ножовки, pila nozhovka].

A fragment of the blade from the oldest saw was found in a layer from the second half of the 10th century (27-30-880). One end of the saw blade, 65 mm in length, has been preserved. The blade is 16 mm wide, flat, and very thin, with a thickness of 0.9 mm. The fragment has 12 teeth preserved. The tooth interval is about 5 mm. The teeth are in the shape of isosceles triangles, about 3 mm tall. The teeth are set about 1.8 mm apart. The teeth have a common offset, that is, where the even-numbered teeth are set to the right, and the odd-numbered teeth to the left.

An entire hacksaw blade (illustration 18, 2) was found in an 11th-century layer (21-25-21). The entire blade was preserved, as well as a broken off section of the handle, consisting of an extension of the blade (similar to a knife handle). The blade was 390 mm long. The width of the blade was 36 mm at the handle, and 17 mm at the tip. The blade is wedge-shaped, narrowing toward the teeth. The blade thickness averaged 2.5 mm, with most of the thickness toward the top. The teeth are strictly placed in a straight line. The teeth are larger at the handle than at the tip. The tooth interval at the handle is about 5.5 mm, but is closer to 4.5 mm at the tip. The teeth are in the shape of isosceles triangles, measuring 4.6 mm tall at the handle, shrinking to 3.3 mm at the tip. In all, there are 73 teeth on the blade. The teeth angle outwards by around 3.5 mm, in an interestingly regular pattern: the first tooth extends straight down from the blade; the second is bent to the right, the third to the left, then the pattern repeats (illustration 18, 9). The sharpening of the teeth is unusual: the straight teeth are sharpened on both sides, while the left and right teeth are sharpened only on the edge facing the tip of the blade. The iron tang was covered with a wooden handle.

A partial saw blade (22-21-1096) was discovered in a layer from the 11th century (illustration 18, 4). The tip of the blade, measuring 145 mm in length, has survived. The blade is 28 mm wide at the break. The blade is flat, measuring 1.6 mm thick. The fragment has 27 teeth, with an average tooth interval of 5 mm. The teeth are in the shape of isosceles triangles, with a height around 3.5 mm. The teeth angle outwards, with a width of separation about 3.5 mm. The separation is typical, that is, with even-numbered teeth angling to the right, and odd-numbered teeth to the left. Judging by the proportions of the surviving fragment, we estimate that the overall length of the blade was most likely around 350 mm.

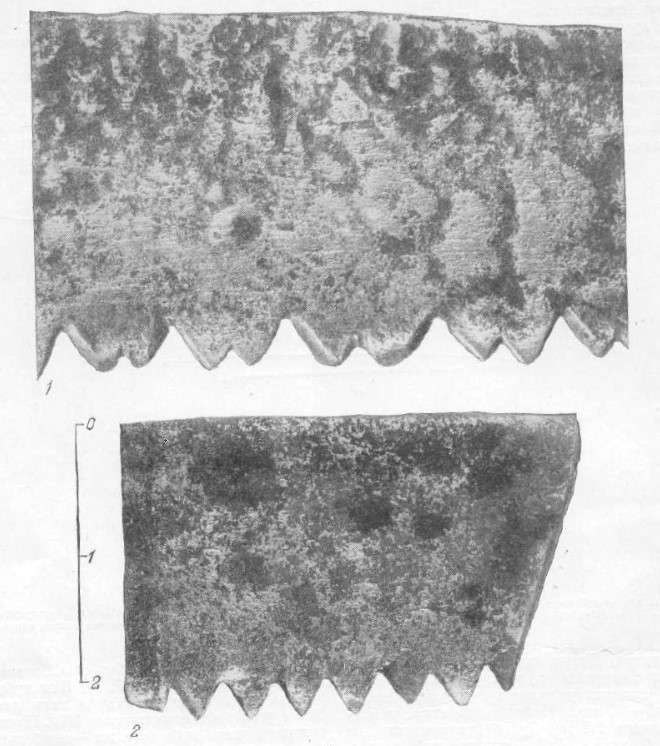

1 – 12th cent. (15-15-963); 2-11th cent. (23-24-905)

Another fragment of a saw blade (23-24-905) was found in a layer from the mid-11th century (illustration 18, 6). Part of the blade has survived, along with the handle tang. This fragment is 70 mm long. The blade is flag, 24 mm wide and 1.3 mm thick. The fragment includes 10 teeth. The tooth interval averages 4.2 mm. The teeth are shaped like isosceles triangles, 3 mm tall (illustration 19, 2). The teeth on this blade are angled outwards widely, with an average spread of 3 mm.

Another partial saw blade (17-20-387) was found in a mid-12th century layer (illustration 18, 5). This was the end of a saw blade, measuring 195 mm long. The blade was 22 mm wide at the break. The blade is flat, with a thickness of 1.4 mm. This fragment includes 40 teeth, with an average tooth interval of 34 mm. The teeth are shaped like isosceles triangles, around 3.5 mm in height. The teeth are angled outwards in a typical fashion, with a spread around 2.5 mm.

A complete saw blade (15-15-953) was found in a layer from the turn of the 12th-13th centuries (illustration 18, 1), inside a carpenter’s workshop. The blade was completely preserved, but the tang for the handle was partially broken. The handle was a direct continuation of the blade, the same as on the blade from the 21st layer. The blade was 450 mm long, and the overall length including the tang was 525 mm. The blade was 43 mm wide at the handle, and 25 mm wide at the tip. The teeth were positioned along a straight line, except that in the central section of the blade, this line is a bit concave in the direction of the blade as a result of multiple sharpenings, because the teeth in this section grow dull more quickly than those on the ends. The teeth are of a large triangular shape, and are doubly pointed, meaning that at the top of each tooth, an additional triangular cut has been made, creating two peaks at the top of each tooth (illustration 19, 1). Overall there are 44 teeth (or 88 small teeth). The interval for the major teeth is 10 mm, with an average height of 4.5 mm. These major teeth are angled outwards in the typical fashion, that is, with even-numbered teeth to the right, and odd-numbered to the left. This spread measures 4 mm. The edges of all teeth, both the major teeth and the small teeth atop them, are sharpened only on the one external side.

In a layer from the mid-13th century, a complete saw blade (13-9-680) was found (illustration 18, 3). It’s handle was straight. The blade was 260 mm long, while the overall length including the tang was 300 mm. The blade was 20 mm at the handle, and 10 mm at the tip. The blade was flat, around 2.5 mm thick. The teeth were located along a straight line. The teeth were triangular, around 2.7 mm tall. The tooth interval was 5 mm. In all on the blade, there are 50 teeth. The teeth are set according to the typical method. The spread measures 3 mm (illustration 18, 10).

We performed microstructural analyses on 4 of the samples (23-24-905; 17-20-387; 27-30-880; 22-21-1096). On all of the samples, we revealed a homogenous structure of low-carbon steel. The 10th century blade (27-30-880) was in a heat-treated state; the sample revealed a sorbite structure, that is, the blade for this saw was hardened followed by high tempering.

Bow ripsaw [Rus. луковая продольная пила, lukovaja prodol’naja pila].

A fragment of a blade from this type of saw was found in a layer from the turn of the 13th-14th centuries (10-15-220). The fragment was 100 mm long, and 22 mm wide. The blade was conical, that is, the cross-section is wedge shaped. The base of the wedge faces the teeth. The teeth are one-sided and 2.2 mm tall (illustration 18, 7, 8). The tooth interval is 8.5 mm. The sawtooth angle is 90°, while the cutting angle is 109°. The cutting edge of the teeth (the maximum thickness of the blade) is 2.5 mm. This type of blade would have been stretched by a wooden frame. Based on an analogous find from Knjazha Gora,[29]Collection of the Kiev Historical Museum, inv. no. S67005. this Novgorod blade may have originally been 500-600 mm in length. A saw with this sort of blade and teeth would have been used only for longitudinal sawing of wood. The blade is completely made of steel.

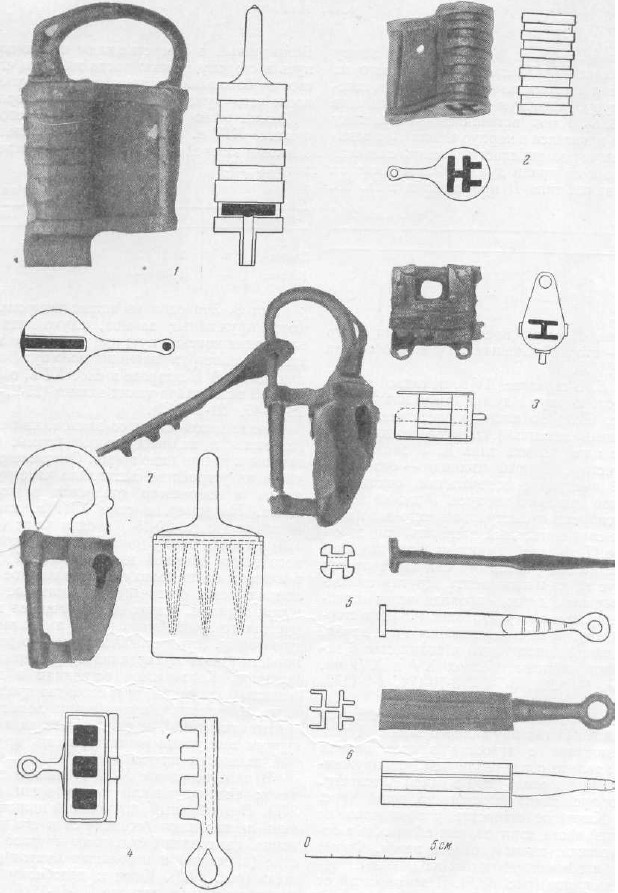

Chisels [долото, doloto]

1-Late 12th cent. (15-14-1003); 2-Late 13th cent. (10-14-1229); 3-Late 14th cent. (6-8-1027); 4-late 11th cent. (20-21-1075); 5-13th cent. (12-11-488); 6-11th cent. (25-27-1007)

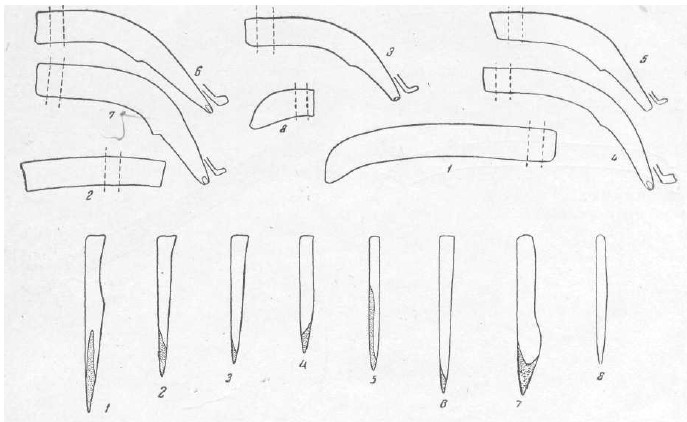

In a previous article, I stated that medieval Russian chisels were divided into two types: socketed and simple.[30]Kolchin, Chernaya metallurgija…, pp. 108-111. Following study of Novgorod and additional analogous finds, I have determined that this statement was not quite correct. The difference in types of chisels now appears to be chronological, rather than technological. Large, socketed chisels were characteristic for the end of the first millenium CE. In the 10th century, a new type of chisel appeared – completely metallic simple ones. Large, socketed chisels disappeared in the 11th century. In the Nerevsky dig, in all 28 chisels were discovered. Of these, one was large and socketed, found in a mid-10th century layer. The remaining 28 chisels were all simple and completely metallic. They were found in all layers up to and including the 15th century.

From the socketed chisel (28-33-104), only the cutting surface is well preserved; the socket is partially destroyed. As with analogous chisels from the Podbolot’e, Maksimovskoe, Ljadinskoe, and other burial grounds, this was a large tool with a reinforced, wide blade. The chisel was 30 mm wide, and 150 mm tall from the tip to the socket. Judging by the proportions of the lower parts of the socket, it’s diameter in the upper half would have been no less than 50 mm. This iron chisel had a welded steel blade.

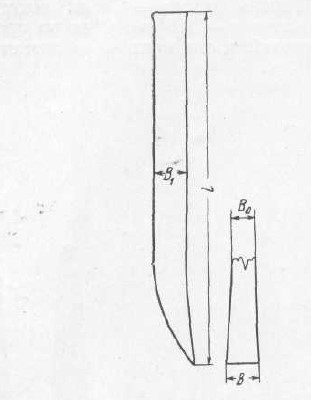

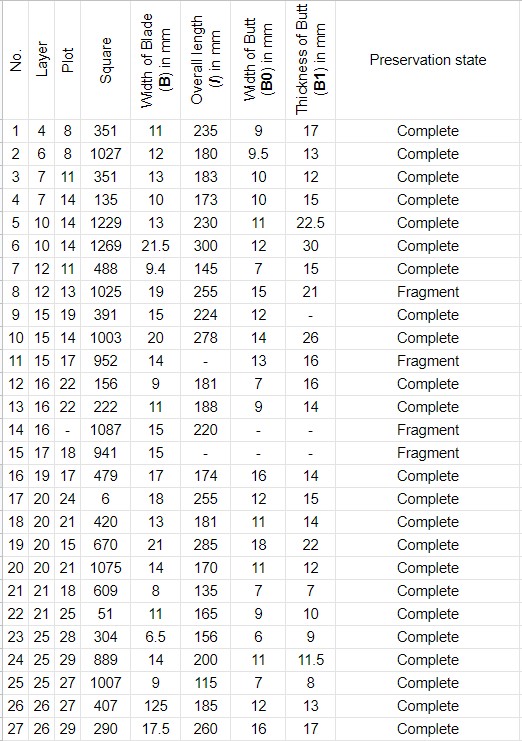

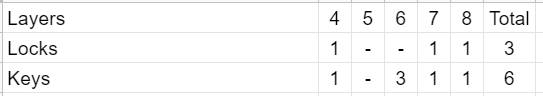

Simple, all-metal chisels appear as four-sided metallic rods with a blade on one end and a butt on the other (illustration 20). The construction of the blade for all chisels was completely analogous to modern practice. An elongated blade with a beveled edge was constructively most rational for chiseling wood. The blade’s cutting angle ranged from 17° to 20°. The dimensions of the chisels and their distribution by layer is shown in Table 10. Based on this table, we can see that, independent of time period, chisel blades ranged from the narrow (6.5 mm) to wide (21.5 mm). Depending on the width of the blade, chisels sometimes came in decidedly large lengths (300 mm).

The technology for creating chisels, beginning from the 10th century, was uniform and characteristic for medieval Rus’. This involved welding a steel blade into an iron body. Microstructural analysis on 2 chisel blades (17-18-941, 12-13-1025) and macro-etching of 5 examples (6-8-1027, 15-14-1003, 19-17-479, 20-15-670, 25-28-304) showed that all of these examples had welded steel blades. The microsection of chisel 12-13-1025 showed a large steel plate bevel-welded to the iron body (illustration 24, 2). The welding seam was thin and very clean (illustration 14, 6). The structural state of the weld was martensite, which provides evidence of blade hardening.

The microsection of chisel 17-18-941 likewise revealed a welded steel blade, but with a different technological method (illustration 24, 1). Thin sheets of steel were welded to either side of the iron chisel blade, which has survived in an annealed state. The structure of the welded steel sheets was ferrite with perlite with carbon content around 0.4%.

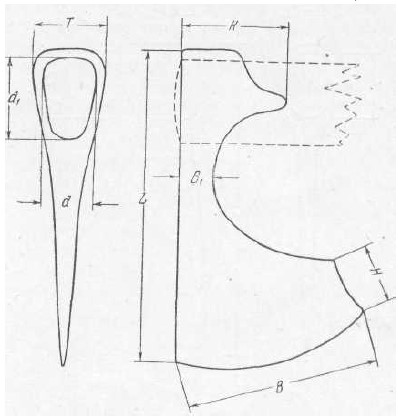

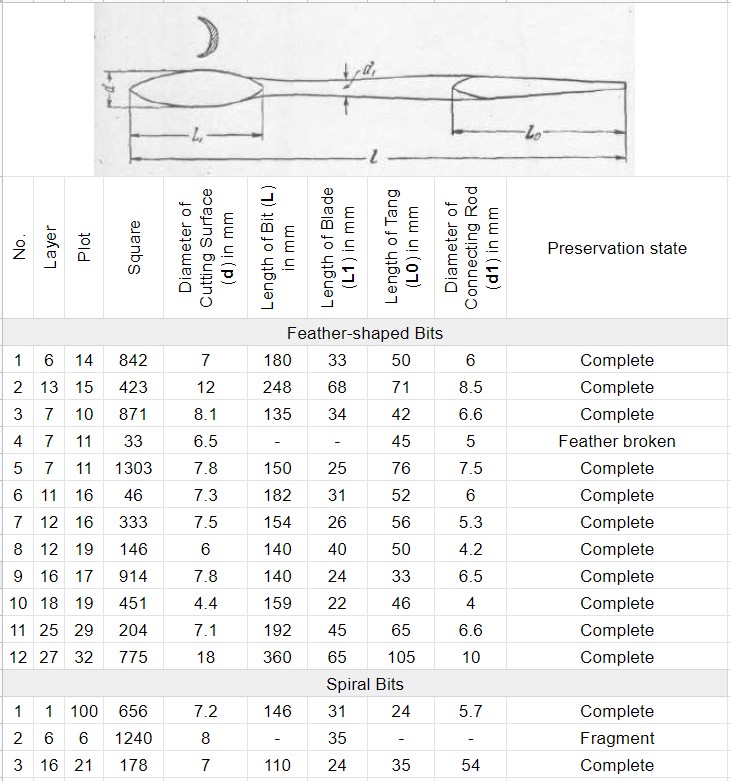

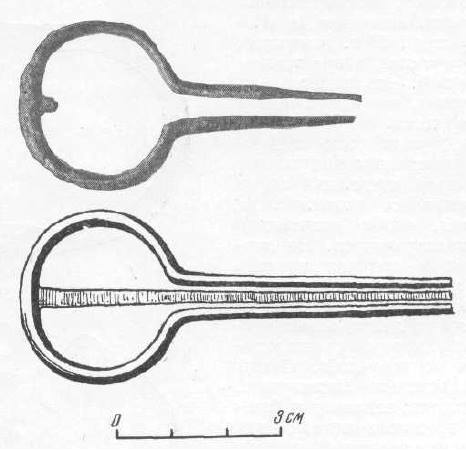

Drill bits [Rus. сверло, sverlo]

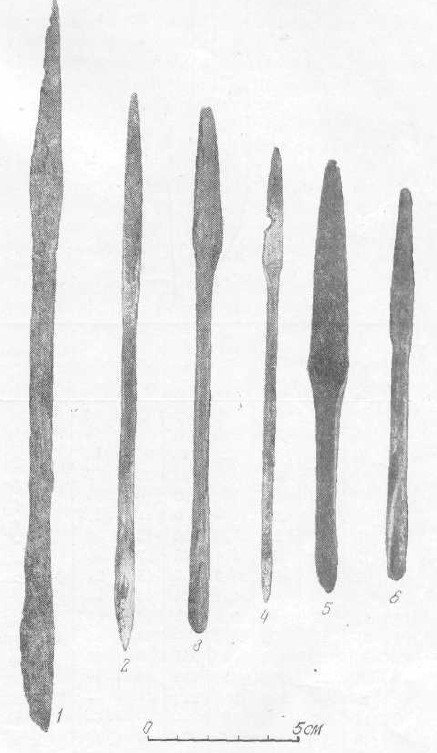

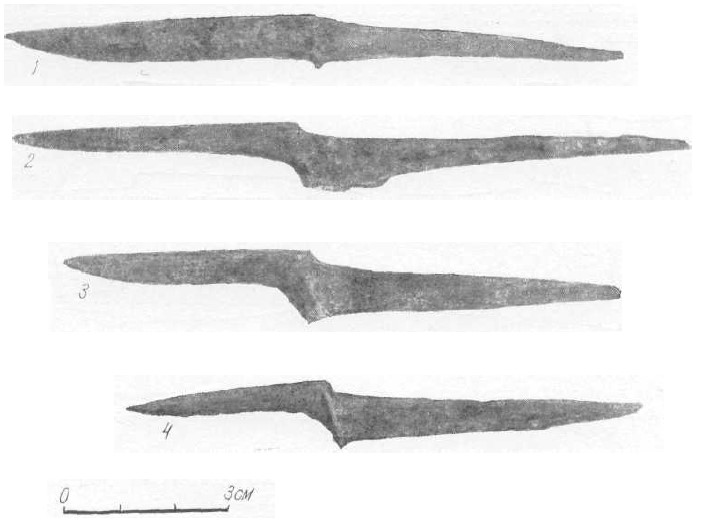

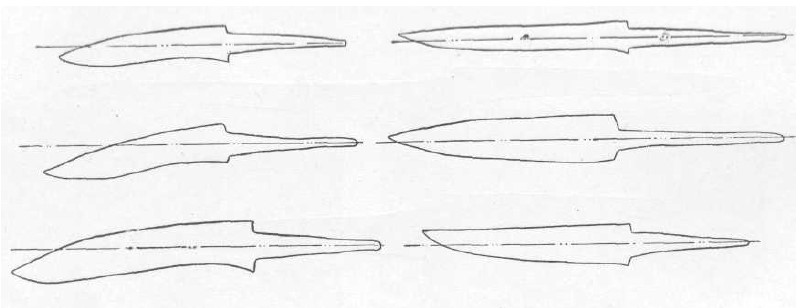

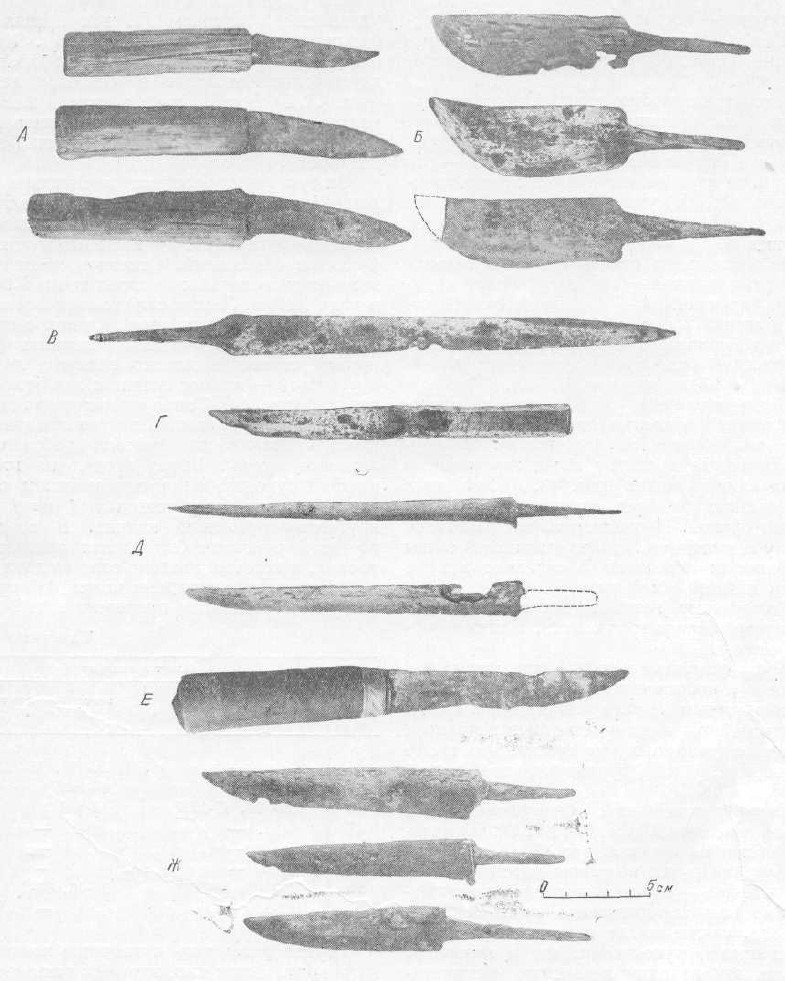

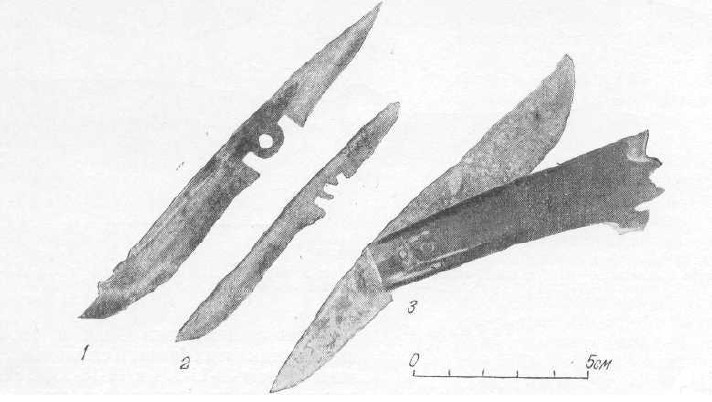

1-13th cent. (13-15-423); 2-11th cent. (25-29-204); 3-late 14th cent. (6-14-842); 4-12th cent. (18-19-451); 5-14th cent. (7-11-1303); 6-14th cent. (7-10-871)